Waxes In Dentistry

Question 1. Write a short note on the classification of dental waxes.

Or

Classify dental waxes.

Answer:

During the construction of dentures and many other appliances waxes are used as a modeling material, different types of waxes are used to prepare patterns for alloy casting.

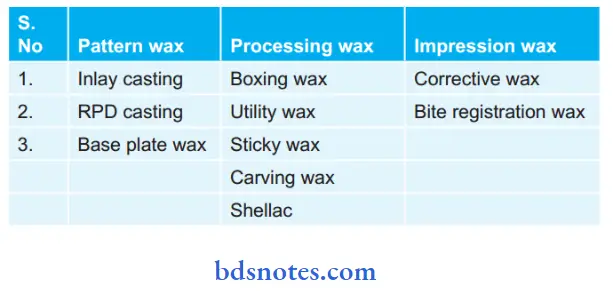

Classification of Dental Waxes:

Read And Learn More: Dental Materials Question And Answers

1. According to use in dentistry:

2. According to origin:

Mineral waxes : Paraffin wax and microcrystalline waxes (distillation product of petroleum)

Plant waxes : Carnauba wax, candelilla wax, Japan wax, and cocoa butter

Insect waxes : Bee wax

Animal wax : Spermaceti (obtained from the sperm of a whale).

ISO Classification (ISO 15854: 2005) for Casting Inlay and Base Plate Wax:

As per ISO two types of wax are present which are sub-classified based on their characteristics which represent their hardness.

- Type I (casting wax) — For cast metal restorations

- Class 1: Soft.

- Class 2: Hard.

- Type II (base plate wax)—For denture bases and occlusal rims.

- Class 1: Soft

- Class 2: Hard

- Class 3: Extra hard.

Question 2. Write a short note on blue inlay wax.

Or

Write briefly on blue inlay wax.

Or

Discuss the composition, properties, manipulation, and uses of inlay casting wax.

Or

Write about the manipulation and properties of the inlay wax.

Or

Write composition, properties, manipulation, and uses of blue inlay wax.

Or

Write a short note on inlay waxes.

Or

Write a brief on inlay casting wax.

Or

Write a short note on inlay casting wax.

Or

Write short notes on the composition and ideal requirements of inlay casting wax.

Or

Write about the composition, ideal properties and uses of inlay wax.

Or

Write briefly on the properties of inlay wax.

Or

Write a short note on ideal requirements for inlay wax.

Or

Write the long answer on inlay wax.

Or

Classify waxes used in dentistry. Describe the composition, properties, and ideal requirements of blue inlay wax.

Or

Describe the composition and ideal requirements of inlay casting wax.

Answer:

Blue inlay wax: Blue inlay wax is a type of pattern wax that is used for making patterns for inlays, crowns, and bridges which is later replaced by metal or alloy.

Ideal Requirements of Blue Inlay Wax:

- When soften, the wax should be uniform, there should be no graininess or hard spots in the plastic material.

- The color should contrast with die.

- There should be no flakiness, or roughening of the surface when the wax is molded after softening.

- The wax should not pull or chip during carving.

- During burnout (500°C), it should vaporize completely without residue.

- The wax pattern should be rigid and dimensionally stable till it is eliminated.

- It is sufficiently plastic slightly above the mouth temperature and get rigid when cooled to mouth temperature.

- Wax should have good flow when heated and it set rigidly when cooled.

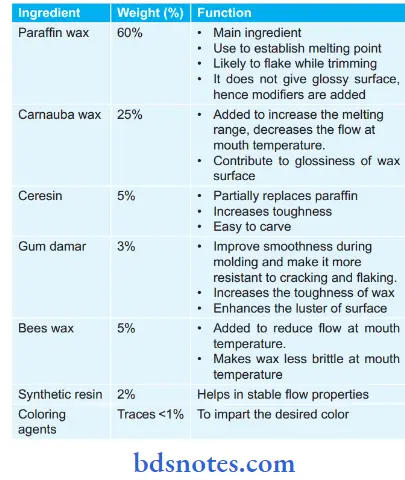

Composition of Blue Inlay Wax:

Classification of Blue Inlay Wax:

According to ISO 15854:2005

- Class 1: Soft extraoral or laboratory use

- Class 2: Hard intraoral use.

According to ADA specification no. 4 there are two types of inlay waxes, i.e.

- Type I — Medium wax: Used in the fabrication of direct patterns

- Type II — Soft wax: For indirect technique for inlays and crowns.

Supplied as of Blue Inlay Wax: Blue, green, or purple sticks are also available as small pellets and cones.

Properties of Blue Inlay Wax:

1. Physical properties

Type I inlay casting wax is meant for use in the mouth, whereas. Type II wax is used in the laboratory. Both would have slightly different properties.

Flow: Flow is a change in shape under an applying force.

- Flow is highly dependent upon time and temperature.

- Flow is denoted as a percentage of actual height but as time approaches the melting range of flow increases.

- For pattern wax, the flow is generally not desirable at room temperature. Since it results in permanent distortion of the wax pattern.

- According to ADA specification no.

- 4. At 45°C – Class 1 and Class 2 should have a flow between 70 to 90%

- At 37°C – Class 2 should not flow more than 1%.

- At 30°C – Class 1 should not flow more than 1%.

- Class 1 inlay wax: This type melts and flows when heated to 45°C. Temperature is tolerated by the patient. Good flow at this temperature ensures good reproduction of the inlay cavity. Wax cools down and hardens at 37°C (mouth temperature), allowing the operator to carve and shape it in the mouth.

- Class 2 inlay wax: It hardens at 30°C (room temperature). This wax is more suitable for the laboratory. Flow characteristics are not suitable for use in the mouth.

- Homogeneity: Components of the wax should be evenly distributed since it should have the same property throughout the solid.

- Contact Angle: At wax is melted, it should wet the surface of the material to which it is added and should spread easily on, it, i.e. it should have a low contact angle.

- Ductility: Inlay wax consists of moderate ductility. This allows the wax to be more plastic so that it will deform rather than get fractured. This property also allows the wax to be carved or burnished.

- Residual Stress: This property is responsible for the distortion of wax pattern. Residual stress is minimized by working the wax at a high temperature or by preheating die. For minimizing the residual

stress molding of wax is done slightly above the melting point or above transitional temperature.

2. Thermal property:

- The thermal conductivity of waxes is low. It takes time to heat the wax uniformly and to cool it to room temperature.

- The coefficient of thermal expansion of inlay wax is high. Its value is 350 × 10-6 °C.

- Its thermal changes are higher than any other dental materials.

- The addition of modifir wax, i.e. bees wax and carnauba wax decreases the coefficient of thermal expansion of inlay wax.

- This decreases the susceptibility of wax to distortion on cooling.

- This property is a more significant indirect technique because contraction of the pattern can occur when it is taken from mouth to room temperature.

3. Chemical property: When inlay wax is pyrolyzed, oxidation completely transforms in water vapor and carbon dioxide, so there is no residue left.

Manipulation of Blue Inlay Wax:

- Direct Technique:

- Hold the stick of wax over the visible flame and rotate it rapidly until it becomes plastic taking care not to volatile the wax.

- The wax is inserted into the cavity and it is held under finger pressure ask the patient to bite the wax, while it solidifies. The wax should be allowed to cool gradually to mouth temperature.

- Indirect Technique:

- Dipping method: In full crowns die can be dipped repeatedly in hot liquid wax. Wax should be allowed to cool, carve, and is removed from the dye.

- Softening in warm water: Technique is not recommended.

- Addition: Wax is melted and is added in layers by a spatula or brush.

Polishing of Blue Inlay Wax: Polishing is done by rubbing with silk cloth.

Uses or Application of Inlay Casting Wax or Inlay Wax

- It is used in the fabrication of direct patterns

- It is used in indirect techniques for inlays, crowns, and FPDs.

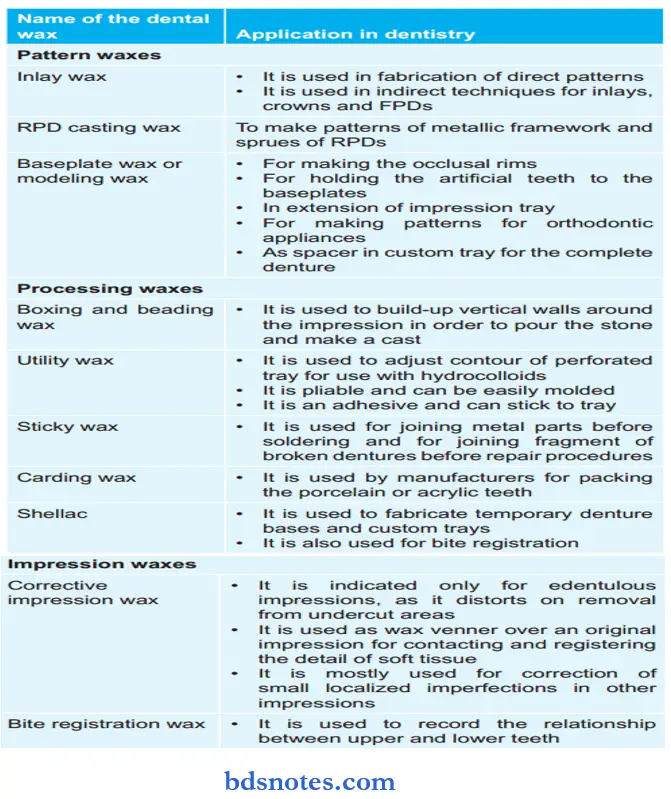

Question 3. Write a short note on the dental application of waxes.

Answer:

Question 4. Write a short note on pattern waxes.

Answer:

Pattern waxes are of three types viz:

- Inlay casting wax

- RPD casting wax

- Baseplate wax.

1. Inlay casting wax: Blue inlay wax is a type of pattern wax that is used for making patterns for inlays, crowns, and bridges which is later replaced by metal or alloy.

Ideal Requirements of Blue Inlay Wax:

- When soften, the wax should be uniform, there should be no graininess or hard spots in the plastic material.

- The color should contrast with die.

- There should be no flakiness, or roughening of the surface when the wax is molded after softening.

- The wax should not pull or chip during carving.

- During burnout (500°C), it should vaporize completely without residue.

- The wax pattern should be rigid and dimensionally stable till it is eliminated.

- It is sufficiently plastic slightly above the mouth temperature and get rigid when cooled to mouth temperature.

- Wax should have good flow when heated and it set rigidly when cooled.

Uses or Application of Inlay Casting Wax or Inlay Wax:

- It is used in the fabrication of direct patterns

- It is used in indirect techniques for inlays, crowns, and FPDs.

2. RPD Casting Wax: Partial denture casting wax has different handling and appearance properties as compared to inlay casting wax.

Property of RPD Casting Wax:

- RPD casting waxes are tacky and highly ductile, they adapt easily and stick on refractory cast.

- This wax accurately copies the surface details against which

it is adapted. - Wax comes in preformed shapes, so it is easy to assemble.

- As wax pattern is completed, it is invested and ignited.

Uses RPD Casting Wax: For making patterns of metallic framework and sprues of the removable partial denture.

3. Baseplate Wax:

It is also known as modeling or Type 2 wax. These wax are easy to carve. They cannot chip or break during try-in. They can boil without leaving any residue.

Classification of Baseplate Wax:

- Type I: Soft—for building veneers

- Type II: Hard—in mouth in normal climate

- Type III: Extra hard—used in tropical climates.

Composition of Baseplate Wax:

Uses of Baseplate Wax:

- For constructing occlusal rims

- For making contour of the denture after setting

- For constructing patterns of orthodontic appliances and other prostheses which are constructed of plastics.

Question 5. Discuss compensation casting shrinkage.

Answer:

Compensation of Casting Shrinkage:

For Gypsum-bonded Investments

- Normal expansion.

- Hygroscopic setting expansion.

- Thermal expansion.

1. Normal Setting Expansion:

As the water gets mixed with investment powder, water surrounds the calcium sulfate crystals and convert them into calcium α–dihydrate. Setting expansion enlarges the mold partially for casting shrinkage of gold alloys. The effectiveness of setting expansion depends on the thermal expansion of the wax pattern.

Expansion in the wax pattern is due to exothermic heat which is released from the investment while setting. As the soft is the wax and thin is the wax pattern, more is the expansion since the investment can move soft and thin wax more easily. ADA specification N o. 2 for type I investment permits maximum setting expansion in air of 0.5%. Modern investments show a setting expansion of 0.4%.

2. Hygroscopic Setting Expansion:

Hygroscopic setting expansion is a continuation of normal setting expansion when it is allowed to set in the presence of water. Water has to be incorporated before the setting of the investment takes place. This water replaces the water of hydration and prevents the confinement of crystal growth. So the crystals continue to grow outward in the presence of water which causes more expansion.

The water here is provided to gypsum crystals from the wet liner which is placed over the inner surface of the casting ring or from the exposed surface of the investment which is immersed in water. Hygroscopic setting expansion is 5 to 6 times that of normal setting expansion. ADA specification N o. 2 for type II investments requires a minimum of 1.2% and a maximum of 2.2% expansion.

3. Thermal Expansion:

In the case of gypsum investment thermal expansion is achieved by placing the mold in the furnace at a temperature below than 700°C (If the temperature is more than 700°C, the investment is

a breakdown, and gases are released which contaminate the gold alloy). The thermal expansion of gypsum-bonded investment is directly related to the amount and type of silica.

- A considerable amount of quart or allotropic form of silica is necessary to counterbalance the contraction in the gypsum during heating.

- When investment is heated the gypsum contracts between 200 to 400°C and a slight expansion takes place between 400°C to 700°C and a large contraction occurs after this.

- If a considerable amount of allotropes of silica is present in the investment.

- This contraction can be eliminated and changed in expansion.

- Because when heated, quart or crystabolite changes its crystalline form this occurs at a transition temperature.

- Quart when heated, inverts from “low” form known as alpha quart to a “high” form known as beta quartz at a temperature of 370°C.

- Crystabolite similarly when heated inverts from ‘low’ or alpha crystalline to high or beta crystabolite form at temperatures between 200°C and 270°C.

- The density changes (decreases) as alpha form changes to beta form with a resulting increase in volume and a rapid increase in linear expansion.

For Phosphate-bonded Investments:

The expansion of mold is desirable to compensate for casting shrinkage. Expansion of phosphate investment occurs from three sources, i.e.

- Wax pattern expansion: Heat during setting allows significant impression of the wax pattern.

- Setting expansion: It is 0.7 to 1%.

- Thermal expansion: It is 1 to 1.5%.

Question 6. Write the importance and ideal requirements of dental wax.

Answer:

Importance:

- Their most important uses are as patterns, which are used to shape the molds in which resin and cast metal restorations are made.

- Dental waxes are important in the construction of dental prosthetic appliances.

Ideal Requirements of Dental Wax:

- When soften the wax should be uniform.

- The color should be contrasted with the die.

- There should be no flakiness, or roughening of the surface when the wax is molded after softening.

- The wax should not pull or chip during carving.

- During burnout (500°C), it should vaporize completely without residue.

- The wax pattern should be rigid and dimensionally stable till it is eliminated.

- It is sufficiently plastic slightly above the mouth temperature and gets rigid when cooled to mouth temperature.

- Wax should have good flow when heated and it set rigidly when cooled.

Question 7. Write in brief on dental wax.

Answer:

Dental wax can be defined as a thermoplastic molding material that is solid at room temperature and when subjected to moderate temperatures becomes a low viscosity liquid.

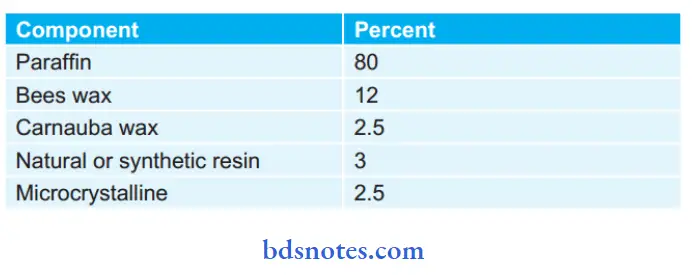

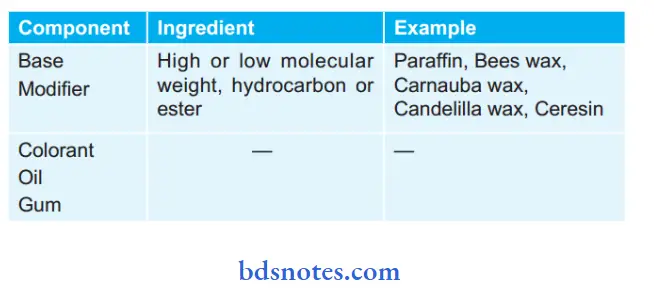

Composition of Dental Wax:

Application of Dental Wax:

- Used in the formation of inlay patterns.

- Used in a dental laboratory to box impressions prior to cast pouring with gypsum.

- Used as a base plate for registration of jaw relation.

- Used as a casting wax to establish minimum thickness to certain areas.

- Used as a utility wax to prevent distortion of impression materials.

- Used as a sticky wax to join fractured parts together.

- Used as a corrective impression wax to contact and register the detail of soft tissue.

- Used as a bite registration wax.

Properties of Dental Wax:

- Melting Range:

- Waxes have melting ranges rather than melting points. Mixing of waxes may change their melting range. The melting range varies depending on its use.

- Thermal Expansion: Waxes expand when subjected to a rise in temperature and contract as the temperature is decreased. Dental waxes and their components have the largest coefficient of thermal expansion among the materials used in restorative dentistry. Temperature changes in wax patterns after removal from the mouth can produce inaccuracies in the finished restoration.

- Mechanical Properties: The elastic modulus, proportional limit, and compressive strength of waxes are low compared to other dental materials. These properties are strongly dependent on the temperature. As temperature decreases, the properties improve.

- Flow: Flow is an important property, especially in inlay waxes. When melted, the wax should flow readily into all the parts of the die.

- Flow is dependent on:

- The temperature of the wax

- Force applied

- The length of time the force is applied.

- Flow increases as the melting point of the wax is approached.

- Residual Stress: Regardless of the method used to make a wax pattern, residual stresses will exist in the completed pattern. The stress may be compressive or tensile in nature.

- Ductility: Like flow, the ductility increases as the temperature of the wax is increased. In general, waxes with low melting points have greater ductility than those with high melting points

Leave a Reply