Lab Procedures

Question 1. Write short note on soldering and welding.

Or

Write briefly on soldering and welding.

Or

Write short note on soldering.

Answer.

Soldering

- Soldering is defied as a process of joining metals by the use of a filler metal which has a substantially lower fusion temperature than that of the metals being joined.

- Dental solders: Dental solders are alloys that are used as intermediary or a filer metal is joining two or more metallic parts.

- Most dental solders are composed of gold, silver, copper, zinc, tin and nickel.

Materials Used in Soldering

- Solder: Silver solders are mostly used and they are the alloys of silver, copper and zinc in which indium and tin are added to decrease fusion temperature.

- Flux: It is made up of boric acid, borax and potassium floride. It removes the oxide coating over substrate material when filler metal become molten and is ready to flow.

- Antiflux: Graphite is used. It prevents flow of molten solder over areas coated.

Read And Learn More: Orthodontics Question And Answers

Types of Soldering

In dental practice soldering can be carried out in two methods:

- Investment soldering.

- Free hand soldering.

Investment Soldering

It is carried out whenever the area of contact between the metallic parts being joined is large.

The procedure involves the embedding of the metallic parts in an investment leaving a gap of about 0.13 mm between the metals.

Free Hand Soldering

Most of the soldering procedures in orthodontics falls in this category.

The process involves soldering two metallic parts together after adequate stabilization without use of investment.

Application of Soldering in Orthodontics

- Soldering is used to join parts of orthodontic appliance.

- Soldering can be used to fasten attachment to bands.

Steps in Soldering

- Clearing the surface to be joined—to remove dirt and other surface contaminants.

- Assembling the parts to be joined using plaster or orthophosphate cement. A gap of about 0.5 mm should exist between the parts to be joined.

- Selecting the right solder and flux: the solder selected should be compatible with the metal in aspects of strength and color. They should exhibit a lower fusion temperature.

- Selection of a proper joint: Between metals being joint, this greatly enhances strength of joint. Here the point of contact do not offer adequate strength when two wires are joined together. It is beneficial to wrap one of the wire around another.

- Application of flux: Flux applied between the gaps in the parts also covers a portion of parts being joined. The flow of solder is limited by using anti-flx.

- Heating and introduction of solder: The area to be joined is heated using a soldering torch. The solder melts and encases the joint.

- Quenching: The assembly is immediately quenched in water so as to limit the spread of heat.

Welding

Welding involves the joining of two or more metal pieces directly under pressure, heat or both without the introduction of a filler material so that a localized union establish between two parts.

- Cold welding is done by hammering or pressure.

- Hot welding uses heat to melt the metals being joined

- The type of welding used to join orthodontic components is called spot welding.

Parts of Welder

- Electric transformer: It decreases the voltage of main supply.

- Copper electrodes: They carry current to work pieces

- Pressure mechanism: It keep working pieces pressed in contact.

- Timer switch: Controls duration of flow of current.

- Heat is calculated by the formula H= I2RT.

- H denote heat in joule.

- I denote current in ampere.

- R denote resistance in Ohm.

- T denote current duration in second.

Principle of Spot Welding

- Heat and the pressure are two basic principles which are involved in the spot welding.

- Electric current should be made to pass via a step down transformer for obtaining the low voltage and high amperage current which is conducted via two copper electrodes on either side of metals being joined.

- Resistance offered by stainless steel to current of high amperage generates very high temperature at electrodes. So area of metal under the electrodes becomes plastic.

- Copper electrodes simultaneously apply pressure on metals and squeeze the metals into each other.

- It is very important that the passage of current at weld spot should be of short duration i.e. not more than 1/10th of the second. If incase the current is passed for the longer duration of time, it leads to weld decay because of precipitation of carbides from the metal. So most of the modern welders have electronic timer which help in discharging the current of very short duration.

- Welding of the stainless steel depend on proper use of following three variables:

- Current flowing via the circuit.

- Time during which the current is allowed to flow.

- Mechanical pressure applied at the welding heads.

Application of Welding in Orthodontic

- Joining of metal strips during banding.

- Fixing attachments such as brackets and molar tubes onto bands.

Procedure of Spot Welding

- Select the proper electrode for thickness or shape of material to be welded. Use a broad electrode for thin materials and narrow for thick material.

- Clean the electrodes of the welder to remove any carbide precipitate. Surface of each electrode should be smooth, flat and perpendicular to its long axis.

- As electrodes are together, they should be in complete contact.

- Welder has a timer, which is set to the required reading.

- Metals which are to be joined should be placed between two electrodes and switch should be turned on.

- Maintain the electrode pressure for few seconds to obtain a good joint.

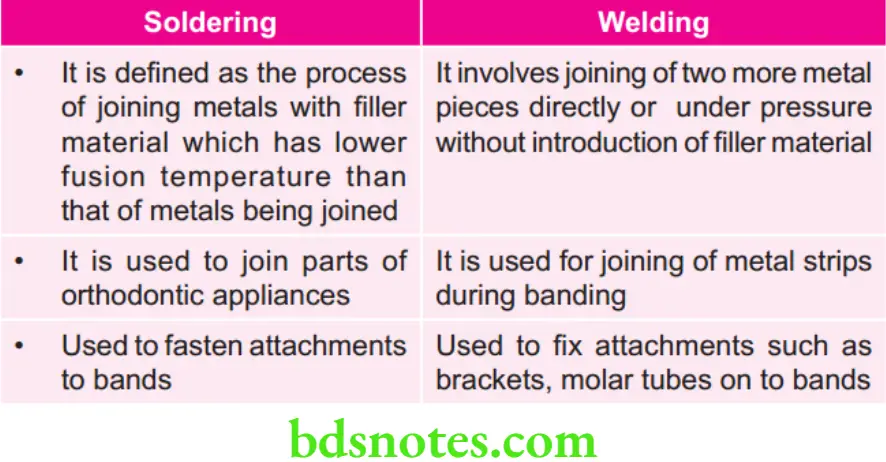

Question 2. Briefly differentiate between soldering and welding.

Answer.

Leave a Reply