- It is often necessary to construct a dental appliance as separate parts and then join them together either by a soldering or welding process.

- Dental brazing is covered by ISO 9333.

Terms And Definitions

Metal joining operations are usually divided into four categories: welding, brazing, soldering, and cast-joining.

Welding

The term welding is used if two pieces of similar metal are joined together without the addition of another metal that is, the metal pieces are heated to a high enough temperature so they join together by melting and flowing.

Read And Learn More: Basic Dental Materials Notes

Brazing And Soldering

The words soldering and brazing are used if two pieces of metal are joined by means of a third metal called a filer.

Brazing

- During soldering, metal parts are joined together by melting a filler metal between them at a temperature below the solidus temperature of the metal being joined and below 450 °C.

- In dentistry, the joining of metal parts are done at temperatures above 450 °C, and therefore the operation should ideally be called brazing.

- This is also the term used by the ISO. However, most dentists still prefer to use the word soldering.

- The term ‘brazing material’ is often used interchangeably with the term ‘solder’.

Substrate Metal

- Substrate metal or parent metal refers to the metal parts to be joined.

- In dentistry alloys that can be soldered or welded include alloys of gold, silver, palladium, nickel, cobalt, titanium, etc.

Ideal Requirements Of A Brazing Material (Dental Solder)

- It should melt at temperatures below the solidus temperature of the parent metal.

- When melted, it should wet and flow freely over the parent metal.

- Its color should match that of the metal being joined.

- It should be resistant to tarnish and corrosion.

- It should resist pitting during heating and application.

Types Of Solders Or Brazing Materials

They may be divided into two major groups.

- Soft solders

- Hard solders

Soft Solders

Soft solders have a low melting range of about 260 °C. They can be applied by simple means like a hot soldering iron. They lack corrosion resistance and so are not suitable for dental use, for example, lead-tin alloys (plumbers solders).

Hard Solders

These have a higher melting temperature and greater strength and hardness. They are melted with the help of gas blowtorches or occasionally in an electric furnace. Hard solders are more commonly used in dentistry. They are also used for industrial purposes and in the jewelry trade, for example, gold soldiers and silver soldiers.

Presoldering And Postsoldering

- The term soldering (brazing) refers to the soldering operation performed on metal-ceramic alloys prior to ceramic firing.

- Postsoldering (post brazing) refers to soldering performed on the alloy after ceramic firing.

- Obviously, the properties required of the two soldiers would be different.

- Soldiers used in soldering would be required to permit ceramic bonding as well as withstand the high porcelain filling temperatures.

Applications Of Soldering

In dentistry, they are used as follows.

- For soldering various types of wires in orthodontics.

- In pedodontics, construct various types of space maintainers.

- In fixed prosthodontics

- For joining of various components of field partial prostheses

- Repair of perforations in crowns and bridges.

- To develop contact points in crowns.

- For cutting and rejoining an ill-fitting distorted bridge.

- In removable partial prosthodontics for soldering of clasps.

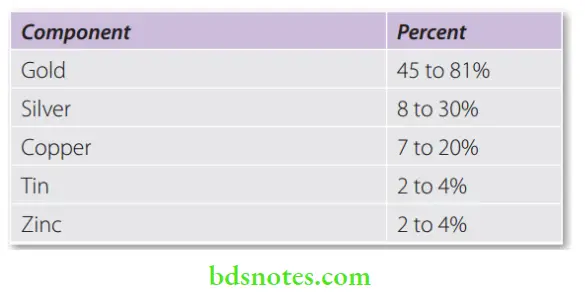

Composition Gold Solders

- In the past soldiers were referred to by a karat number.

- The numbers did not describe the gold content of the solder but rather the carat of gold alloys for which the solder was to be used.

- In recent years the term fitness has been substituted for karat.

- The composition of gold solders varies considerably depending on their finesse.

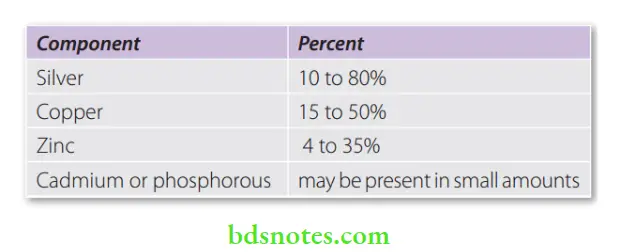

Composition Silver Solders

- Silver solders are less commonly used in dentistry.

- They are used when a low-fusing solder is required for soldering operations on stainless steel or other base metal alloys.

Improving the fi of a fixed partial denture (FPD) through soldering

- The fi of an FDP is often improved when it is cast as two separate pieces.

- Long-span FDPs are especially prone to poor fi because of distortion.

- The two parts of the prosthesis are tried separately in the mouth.

- After the operator is satisfied with the individual fi of the castings, the two pieces are assembled in the mouth and their relationship is recorded and transferred with the help of a suitable index material (impression plaster or zinc oxide eugenol or elastomers).

- The pieces are reassembled in the laboratory and invested using soldering investment.

- The parts are then joined with solder. If done correctly this technique can give superior fitting fixed partial dentures.

Properties Of Dental Brazing Materials

Fusion Temperature

The fusion temperature of the solder should be at least 50 °C lower than the parent metal.

- Gold solders – 690 to 870 °C

- Silver solders – 620 to 700 °C.

Flow

A good flow and wetting (low wetting angle) of the parent metal by the solder is essential to produce a good bond.

Factors Affecting Flow

- Melting range Solders with short melting ranges have a better flow.

- Composition of parent metal Gold and silver-based alloys have better flow than nickel-based alloys.

- Oxides Presence of an oxide layer on the parent metal reduces the flw.

- The surface tension of solder.

Color

- The color of gold solders varies from deep yellow to light yellow to white.

- In practice, most dental soldiers are able to produce an inconspicuous joint.

Tarnish And Corrosion Resistance

- Tarnish resistance increases as the gold content increases.

- However, lower fitness gold alloys also perform well clinically without any serious tendency to discolor.

- Silver solders have reduced tarnish resistance when compared to gold alloy solders.

Mechanical Properties

- Gold solders have adequate strength and hardness and are comparable to dental cast gold alloys having a similar gold content.

- Silver solders also have adequate strength and are similar to gold solders.

Tensile strength of the brazed joint

According to ISO 9333:2006, the tensile strength of the brazed joint should exceed 250 MPa. If the 0,2 % proof strength of either one or both of the metallic materials to be joined by the brazing material is below 250 MPa, the tensile strength should exceed the lower of the two.

Microstructure Of Soldered Joints

- Microscopic examination of an ideal well-formed soldered joint shows that the solder alloy does not combine excessively with the parts being soldered.

- There is a well-defined boundary between the solder and the soldered parts.

- If the heating is prolonged a diffusion takes place and the new alloy formed has inferior properties.

Fluxes

- The Latin word ‘flux’ means flow. For a solder to wet and flow properly, the parent metal must be free of oxides.

- This is accomplished with the help of a flux.

Function Of Flux

- To remove any oxide coating on the parent metal.

- To protect the metal surface from oxidation during soldering.

Flux of Types

Fluxes may be divided into three activity types.

- Protective: This type covers the metal surface and prevents access to oxygen so no oxide can form.

- Reducing: This reduces any oxide present to free metal and oxygen.

- Solvent: This type dissolves any oxide present and carries it away. Most fluxes are usually a combination of two or more of the above.

Commonly Used Dental Fluxes

The commonly used fluxes are

- Boric and borate compounds

- Fluoride fluxes

Boric and Borate Compounds

Boric acid and borax are used with noble metal alloys. They act as protective and reducing fixes.

Fluorides

- Fluoride fluxes like potassium fluorides are used on base metal alloys and are usually combined with borates.

- They help to dissolve the more stable chromium, nickel, and cobalt oxides.

- Fluoride fluxes should be used carefully around porcelain as it can attack the porcelain.

- Note excess flux should be avoided as it can get entrapped within the filer metal and result in a weak joint.

Fluxes May Be Supplied As

- Liquid (applied by painting)

- Paste

- Powder

- Fused onto the solder

- Preflxed solder in tube form.

Antiflux

- There are times when the operator desires that the solder should not flow out of a specific area.

- The flow can be controlled by the use of an antireflux material.

- The solder will not flow into an area where antiflx has been applied.

- It is applied before the flux or solder is applied.

- Examples of antireflux are graphite (soft lead pencil), rouge (iron oxide), or whiting (calcium carbonate) in an alcohol and water suspension.

Technical Considerations

Heat Source

The heat source is a very important part of brazing. In dentistry, two heat sources may be used

- Flame

- Oven

Flame Brazing Or Soldering

- The most commonly used heat source is a gas-air or gas-oxygen torch.

- The flme must provide enough heat not only to melt the filler metal but also to compensate for heat loss to the surroundings.

- Thus, the flme should not only have a high temperature but also a high heat content.

- The low heat content of fuels leads to longer soldering time and more danger of oxidation.

- Heat content is measured in Btu per cubic foot of gas.

Types of gas fuel

- Hydrogen It has the lowest heat content (275 Btu) and therefore heating would be slow. It is not indicated for the soldering of large FDPs.

- Natural gas It has a temperature of 2680 °C and heat content is four times that of hydrogen (1000 Btu). However, normally available gas is nonuniform in composition and frequently contains water vapor.

- Acetylene It has the highest flme temperature (3140 °C) and a higher heat content than H2 or natural gas. However, it has certain problems. Temperature from one part of its flme to another may vary by more than 100 °C.

- Therefore, positioning the torch is critical and a proper part of the flme should be used. It is chemically unstable and decomposes readily to carbon and hydrogen. The carbon may get incorporated into the Ni and Pd alloys, and hydrogen may be absorbed by the Pd alloys.

- Propane It is the best choice. It has the highest heat content (2385 Btu) and a good flme temperature (2850 °C).

- Butane It is more readily available in some parts of the world and is similar to propane. Both propane and butane are uniform in quality and water-free.

Oven Brazing (Furnace Brazing)

- An electric furnace with heating coils may be used for brazing.

- The furnace also provides heated surroundings, so less heat is lost to other parts of the fixed partial denture and the atmosphere.

Technique Of Soldering

Two techniques of dental soldering are employed to assemble dental appliances

- Freehand soldering

- Investment soldering

Free Hand Soldering

In free-hand soldering, the parts are assembled and held in contact manually while the heat and solder are applied.

Investment Soldering

- In investment soldering, the parts to be joined are mounted in a soldering type of investment.

- The hardened investment holds it in position while the heat and solder are applied.

Steps In Soldering Procedure

- Selection of solder

- Cleaning and polishing of components

- Assembly of the prosthesis in soldering investment

- Application of flux

- Preheating the bridge assembly

- Placement of solder

- Application of hot gas flme to joint and solder

- Cooling of the assembly followed by quenching in water

Technical Considerations For Successful Soldering

- Cleanliness – Metal should be free of oxides

- Gap between parts

- Selection of solder – Proper color, fusion temperature, and flow

- Flux-type and amount

- Flame – Neutral or reducing in nature

- Temperature

- Time

Gap The liquid solder is drawn into the joint through capillary action.

- Therefore, an optimum gap is necessary for proper flow, the strength of the joint and to avoid distortion of the assembly.

- Gap widths ranging from 0.13 to 0.3 have been suggested.

If the gap is too narrow, strength is limited due to

- Porosity caused by the incomplete file

- Flux inclusion

If the gap is too great

- The joint strength will be the strength of the solder.

- There is a tendency for the parts to draw together as the solder solidifies.

Flame

- The flme has multiple zones.

- The portion of the flame that is used should be neutral or slightly reduced.

- An improperly adjusted or positioned flme can lead to oxidation and/or carbon inclusion.

- Once the flme has been applied to the joint area, it should be not removed until brazing is complete.

- Due to its reducing nature, the flme gives protection from oxidation.

Temperature

- The temperature used should be the minimum required to complete the brazing operation.

- Prior to the placement of the solder, the parent metal is heated till it is hot enough to melt the filer metal as soon as it touches.

- A lower temperature will not allow the filer to wet the parent metal.

- A higher temperature increases the possibility of diffusion between parent and filler metal.

Time

- The flame is held until the filler metal has flowed completely into the connection and a moment longer to allow the flux or oxide to separate from the fluid solder.

- Insufficient time increases the chances of incomplete filling of the joint and the possibility of flux inclusion in the joint.

- Excessive time increases the possibility of diffusion. Both conditions cause a weaker joint.

Pitted Solder Joints

Pits or porosities in the solder joint often become evident during finishing. They are due to

- Volatilization of the lower melting components due to heating at higher temperatures and for a longer time.

- Improperly melted or excess flux that is trapped in the solder joint. To avoid such pitting, less flux is applied and the heating should be discontinued as soon as the flux and solder are well melted and flowed into position.

Advantages And Disadvantages of Pitted Solder Joints

Advantages

- Low cost.

- Relative effctiveness.

Disadvantages

- Problems such as oxidation of the parts joined by weld.

- Joint porosity and overheating of the union during the welding process can promote small structural defects and failure of the rehabilitation treatment.

Welding

The term welding is used if two pieces of similar metal are joined together without the addition of another metal. It is usually used to join flt structures such as bands and brackets.

Welding Indications

- In orthodontics, to join flt structures like bands and brackets.

- In pedodontics, to weld bands and other appliances.

- In prosthodontics, to join wrought wire clasps and repair of broken metal partial dentures.

Welding Types

Welding processes used in dentistry are

- Resistance spot welding

- Laser welding

- Plasma arc welding (PAW)

- Tungsten inert gas (TIG) welding

Resistance Spot Welding

- Welding is done by passing an electric current through the pieces to be joined.

- These pieces are also simultaneously pressed together.

- The resistance of the metal to flow of current causes intense localized heating and fusion of the metal.

- The combined heat and pressure fuse the metals into a single piece.

- Welding is done in an electric spot welding apparatus.

- The wires or the band to be welded is placed between the two copper electrodes of the welder.

- A flexible spring attached to the electrode helps to apply pressure on the metals.

- A hand-controlled switch is used to operate the welder.

- On pressing the switch a large current passes through the wires or band between the copper electrodes.

- The combined heat and pressure fuse the metal pieces at that point and join them.

- This kind of welding may also be referred to as ‘spot welding’.

- Prosthodontic appliances are welded in a larger machine.

- The parts to be joined are held together in a clamp.

- A hand or foot-controlled switch controls the current.

- Weld’s joints are susceptible to corrosion because of the precipitation of chromium carbide and consequent loss of passivation.

Tungsten Inert Gas Welding And Plasma Arc Welding

- Plasma Arc Welding (PAW) and Tungsten Inert Gas (TIG) welding are techniques in which a union is obtained by heating materials by an arc established between a non-consumable tungsten electrode and the part to be welded.

- The electrode and the area to be welded are protected by using an inert gas, usually argon or a mixture of inert gases (argon and helium).

- The basic equipment consists of a power supply, a torch with a tungsten electrode, a shielding gas source, and an opening system for the arc.

- The main difference between TIG and plasma welding is the use of a constrictor torch that concentrates the electric arc in plasma welding.

Plasma arc and TIG welding Procedure

- The equipment allows for the adjustment of both the pulse and current which is required for welding.

- After adjusting the machine, screw into one of the claws a structure without use and position the parts to be welded with hands or through specific equipment, which positions the parts to be joined.

- The argon activation is done by a foot pedal. The foot pedal is pressed until the argon flows.

- The buzzer will indicate when contact is made. Quickly release the pedal.

- The weld will be made, and the flw of argon will continue for a few seconds

- . It is possible that in the first few attempts, the electrode will stick to the piece making it necessary to regrind the same.

Plasma arc and TIG welding Advantages And Disadvantages

Advantages

- This allows the execution of welds of high quality and excellent finishing, particularly in small joints.

- The thickness of the joint allows for welding in any position, for example, repairing a removable partial prosthesis.

- excellent control of the weld pool, i.e. the region being welded.

- Less time needed.

- It can be executed directly in the working model.

- The equipment is affordable compared to that of laser welding.

- Allows welding in regions near the resins and porcelains.

- Allows welding with the frameworks in close contact or with minimal space for welding, using filler metal.

Disadvantages:

- A large amount of heat to achieve fusion can cause microstructure transformations. These transformations occurring in the ‘heat affected zone’ can cause material distortion, residual stresses, generation of fragile microstructures, grain growth, cracks, fissures, and changes in mechanical, physical, and chemical properties, among others.

- Insufficient weld penetration in butt-type joints.

- Porosities caused by the inclusion of an argon gas shield may occur in the weld region. These bubbles can initiate fractures leading to the failure of welded structures.

Laser Welding

- A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation.

- The term “laser” originated as an acronym for “light amplification by stimulated emission of radiation”.

- The first laser was built in 1960 by Theodore H. Maiman at Hughes Laboratories.

- Laser is finding increasing applications in dentistry including welding.

- The laser used is a pulsed neodymium laser with a very high power density.

- Among their many applications, lasers are used in optical disc drives, laser printers, and barcode scanners; fiber-optic and free-space optical communication; laser surgery and skin treatments; laser pointers; cutting and welding materials; military and law enforcement devices for marking targets and measuring range and speed; and laser lighting displays in entertainment.

Laser use in dentistry

- Lasers have been used in dentistry since 1994 to treat a number of dental problems.

- But, despite FDA approval, no laser system has received the American Dental Association’s (ADA) Seal of Acceptance.

- That seal assures dentists that the product or device meets ADA standards of safety and efficacy, among other things.

- The ADA, however, states that it is cautiously optimistic about the role of laser technology in the field of dentistry.

- These lasers are different from the cold lasers used in phototherapy for the relief of headaches, pain, and inflmmation.

Dental Applications Of Laser

- Tooth decay- Lasers are used to remove decay within a tooth and prepare the surrounding enamel to receive the filing.

- Curing- Lasers are also used to “cure” or harden composite filings.

- Gum disease- Lasers are used to reshape gums and eliminate pockets.

- Pulpectomy- Remove bacteria during root canal procedures.

- Biopsy or lesion removal- Lasers can be used to remove a small piece of tissue (called a biopsy) so that it can be examined for cancer. Lasers are also used to remove lesions in the mouth.

- Pain relief- Used to relieve the pain of canker sores. Surgical procedures- Like frenectomy, gingivectomy ), healing abutment exposure, incisions, etc.

- Teeth whitening- Lasers are used to speed up the in-office teeth whitening procedures. A peroxide bleaching solution, applied to the tooth surface, is “activated” by laser energy, which speeds up of the whitening process.

- Gum lightening- Laser is used to removing the surface layer of mucosa containing the dark melanin pigment in patients with dark gums. On healing the new mucosa is lighter in color.

- Welding- For joining of metal parts.

How Do Lasers Work in Dentistry?

- All lasers work by delivering energy in the form of light.

- When used for surgical and dental procedures, the laser acts as a cutting instrument or a vaporizer of tissue that it comes in contact with.

- When used for “curing” a filing, the laser takes the role of an intense curing light.

- When used in teeth whitening procedures, the laser acts as a heat source and enhances the effct of tooth bleaching agents.

Laser Advantages

Compared to the traditional dental drill, lasers have certain advantages

- They cause less pain in some instances, therefore, reducing the need for anesthesia.

- They may reduce anxiety in patients uncomfortable with the use of the dental drill.

- They minimize bleeding and swelling during soft tissue treatments.

- They may preserve more healthy teeth during cavity removal.

Laser Disadvantages

- Lasers cannot be used on teeth with fillings already in place.

- Lasers cannot be used in many commonly performed dental procedures. For example, lasers cannot be used to fill cavities located between teeth, around old fillings, and large cavities that need to be prepared for a crown. In addition, lasers cannot be used to remove defective crowns or silver fillings or prepare teeth for fixed prostheses.

- Traditional drills may still be needed to shape the filing, adjust the bite and polish the filing, even when a laser is used.

- Lasers do not fully eliminate the need for anesthesia.

- Laser treatment is more expensive since the cost of the laser is much higher than a dental drill. Lasers can cost between 6 to 7 times the cost of a standard drill.

Different Types of Dental Lasers Used

Many different types of lasers are used in dentistry. They can be used in a wide range of power, ranging, from a fraction of a watt to 50 watts or even more.

- The Erbium YAG laser possesses the potential of replacing the drill. This laser is also used to alter pigmentation in the gingival tissues, providing the patient with pink gums. This laser is commonly used to prepare the patient for a cavity filling.

- The carbon dioxide laser can be used to perform gingivectomy and to remove small tumors. As a laser that does not require local anesthesia, it poses no discomfort for the patient and is practically a bloodless procedure.

- The argon laser is used in minor surgery. Its gas laser releases blue-green light through a fiberoptic cable to a handpiece or microscope.

- The Nd: YAG laser is used in tissue retraction, endodontics, and oral surgery. This laser usually does not require anesthesia. For procedures regarding the gingival pockets, the fier is inserted between the gingiva and the tooth to sterilize and stimulate the tissue, causing the gingiva to adhere to the neck.

- The Diode laser introduced in the late 1990s has been effctive for oral surgery and endodontic treatment. This laser also helps treat oral diseases and correct esthetic flaws. The diode is a compact laser.

- Low-level lasers are less well-known, smaller, and less expensive. Sometimes referred to as “soft lasers” the therapy performed by these lasers is called “low-level laser therapy.” Low-level lasers improve blood circulation and regenerate tissues.

Waterlase (from Biolase)

- The Waterlase combines a laser with an ultra-fie stream of water, which is capable of cutting into tooth, bone, and soft tissues.

- As the stream of water flows into the laser beam, the water molecules become laser energized and create tiny explosions on impact with teeth or soft tissue.

Commercial Names

- elexion Duros, Claros, Nano, Pico (elexxion AG, Germany)

- Dental laser DL 2002 (Dentaurum, Germany)

- Haas Laser LKS (Haas Laser GmbH, Germany)

- Heraeus Haas laser 44P (Heraeus Kulzer GmbH, Germany)

- Bego Laserstar (Bego, Germany)

- The unit consists of a small box that contains the laser tip, an argon gas source, and a stereo microscope with lens crosshairs for the correct alignment of the laser beam with the components.

- The maximum depth the laser can penetrate is 2.5 mm.

- The heat generated is small, so the parts can be hand-held during welding and it can be done close to the ceramic or even resin facings without damaging it.

Laser welding Indications

- Laser welding is used mainly to join titanium components.

- This is because the commercially pure titanium (cpi) used in dentistry for fixed and removable partial denture frameworks is highly reactive in air.

- Ordinary soldering procedures result in a weak joint because of the formation of a thick layer of titanium oxide (especially when heated above 850 °C).

- Laser welding or plasma welding can be done at lower temperatures.

Laser Welding Mechanism

- When the light beam reaches the surface of the metal, the metal absorbs its energy, converting it into heat that penetrates into the interior of the metal by conduction.

- Owing to a high concentration of heat, the metal is taken to its melting point, and a series of events culminates in the formation of a keyhole or spots that will be filled with the melted metal.

Advantages Of Laser Welding

Advantages

- Lower heat generation.

- It can be executed directly in the working model.

- Allows welding in regions near the resins and porcelain portions without fear of damage to these materials.

- No oxide formation because of the inert argon atmosphere.

- Joints are made of the same pure titanium as the components, thus reducing the risk of galvanic corrosion.

- It produces a keyhole that concentrates the energy absorbed in a small region, resulting in high penetration and formation of a narrow heat affected zone (HAZ) that results in less distortion compared to conventional welding methods;

- Less time expended

- Allows welding with the structures in close contact or with minimal space for brazing using filler metal.

Disadvantages

- Residual stress introduced into welding joints is a consequence of the heating and cooling cycles of the welding process. This affects the mechanical behavior of laser-welded structures.

- Argon gas can cause porosities which can lead to the failure of welded structures.

- Insufficient penetration of the laser beam can cause a big defect or internal failure if the equipment is not adjusted properly.

- High cost of the equipment.

Cast-Joining

- Cast-joining is an alternative method of joining metal parts that are difficult to solder such as base metal alloys.

- The two parts are joined by a third metal which is cast into the space between the two.

- The two parts are held together purely by mechanical retention which is achieved by proper flow of the new metal during casting.

- Therefore, if the cast metal is poorly adapted it can result in a weak joint.

- The joint area is ground to make a space of at least 1 mm. Mechanical undercuts are prepared at the interphase.

- The parts to be joined are assembled with the help of an index. Hard inlay casting wax is flowed into the space and a sprue is attached.

- The structure is then invested in a casting ring using suitable casting investment. The wax is burnt out and molten metal is cast into the space.

Radiographic Assessment Of Joints

- Most prosthodontic structures are usually fabricated in commercial laboratories.

- The quality of the structure especially that of the joints can be assessed through a radiograph.

- The structure is placed on a firm and exposed.

- It is turned 90 degrees and exposed a second time on a new film.

- The structure is assessed for defects like porosity and cracks, especially in the joints.

- Porosity and other defects in the joints can weaken the restoration causing it to fail in the mouth during function.

- The best joints are those that are cast as one piece, followed by soldered and cast-joined.

Leave a Reply