Mechanical Properties Of Dental Materials

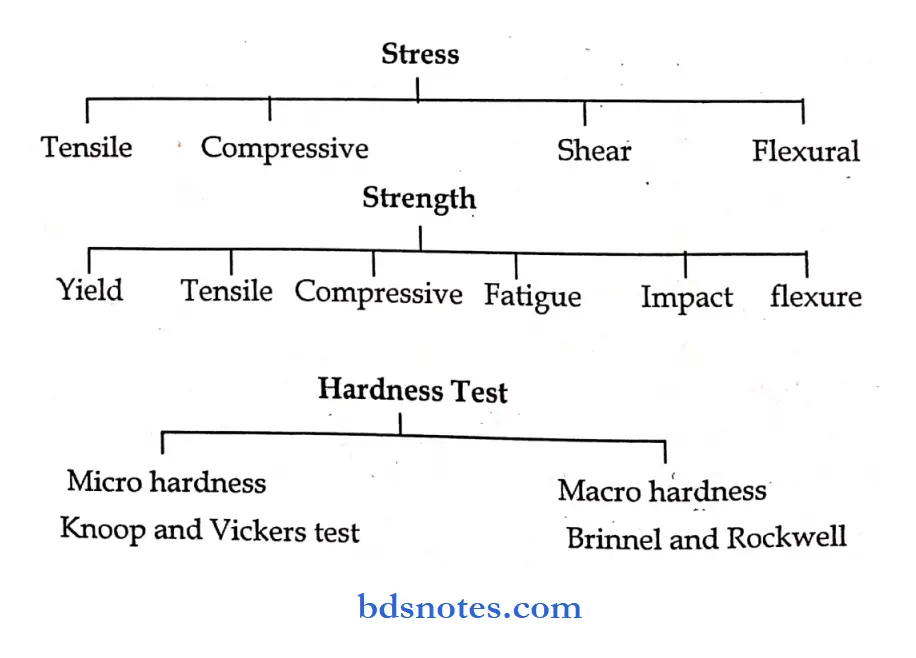

- Stress: Force per unit area within a structure subjected to an external force on pressure.

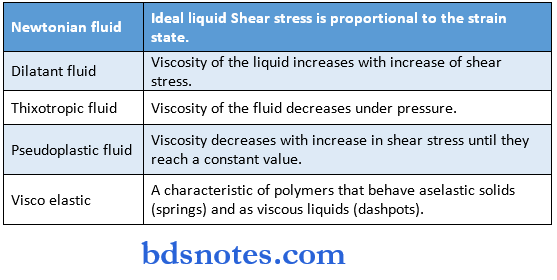

- Shear stress: Ratio of force to the original cross-sectional area parallel to the direction of the force applied to a test specimen.

- Tensile stress: Ratio of tensile force to the original cross-sectional area perpendicular to the direction of applied force

- Compressive stress: Ratio of compressive force to cross-sectional area perpendicular to the axis of applied force

- Strain: Change in length per unit initial length.

- Elastic Strain: Deformation that is recovered upon removal of an externally applied force or pressure.

- Plastic strain: Deformation that is not recoverable when the externally applied force is removed

- Strength: Maximum stress that a structure can withstand without sustaining a specific amount of plastic strain or stress at the point of fracture.

- Tensile strength: Tensile stress at the point of fracture.

- Yield strength: The stress at which a test specimen exhibits a specific amount of plastic strain.

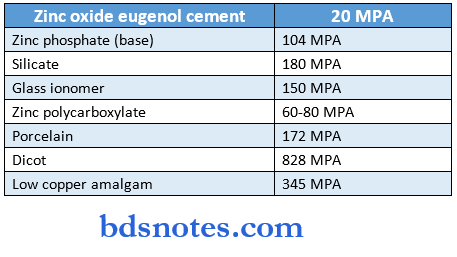

- Compressive strength: Compressive stress within a compression test specimen at the point of fracture.

- Elastic modulus or Young’s modulus: Relative stiffness of material or ratio of elastic stress to elastic strain.

- Proportional limit: Maximum stress at which stress is directly proportional to strain and above which plastic deformation occurs.

- Resilience: The relative amount of elastic energy per unit volume released on unload- ing of a test specimen

- Ductility: Relative ability of a material to deform plastically under tensile stress before it fractures.

- Malleability: Ability of a material to sustain considerable permanent deformation without rupture under compressions as in hammering or rolling into a sheet. Gold is the most ductile and malleable pure metal., 2nd silver.

- Brittleness: Relative to the ability of a material to deform plastically.

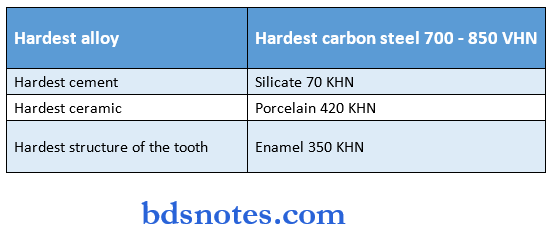

- Hardness: Resistance of a material to plastic deformations typically measured under an indentation load.

- Toughness: Ability of a material to absorb elastic energy to deform plastically before Fracturing.

- Average max. sustainable biting force is approximately 756 N (170 Pounds)

Classification: based on:

Hard ness:

Compressive strength:

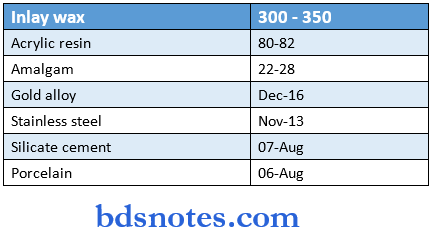

Linear coefficient of thermal expansion(X10-6/0c)

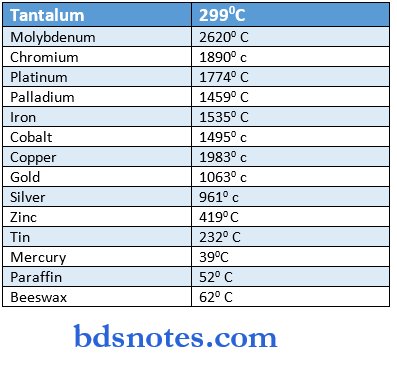

Melting Points

Leave a Reply