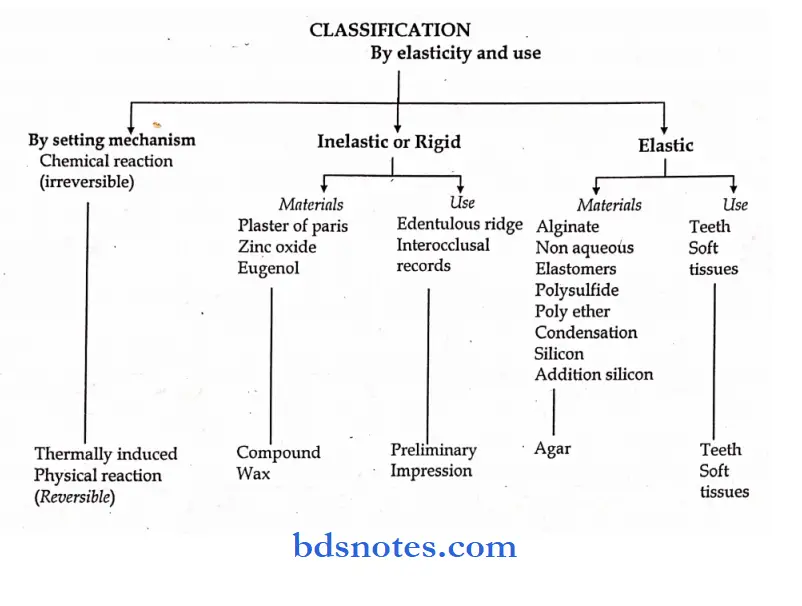

Impression Materials

Die: A reproduction of a prepared tooth made from a gypsum product, epoxy resin, a metal, or refractory material.

Cast: A dimensionally accurate reproduction of a part or parts of the oral cavity or ex- tra oral facial structures produced in a durable hard material.

Model: A positive full-scale replica of teeth, soft tissues, and restored structures used as a diagnostic aid for the construction of orthodontic and prosthetic appliances.

Polymerization: A chemical reaction that transforms small molecules into large polymer chains.

Syneresis: Expression of fluid into the surface of the gel structure.

Imbibition: Process of water sorption.

Read And Learn More: Basic Dental Materials Notes

A review of impression materials

Polysulphides: Also known as

- First dental elastomers

- Rubber-base impression materials Vulcanizing impression materials

- Mercaptan impression materials

- Thiokol

- Contains lead dioxide polymer that gives polysulfide its characteristic brown color.

- The polymerization reaction is exothermic in nature.

- It has a long setting time of 8 to 12 minutes. it has an unpleasant odor and color. both of these properties cause patients discomfort heat and moisture accelerate the setting time.

- It is messy and stains clothes.

- Shows the highest permanent deformation. if maximal accuracy is to

- be maintained, the cast should be poured within the first 30 minutes.

- Shows high polymerization shrinkage due to loss of the by-product (water).

- Polymerization shrinkage and permanent deformation can be minimized by taking a minimum quantity of impression material and by using the custom acrylic tray.

- Shows the highest tear strength.

- Hydrophobic in nature. So the impression area should be dried before making an impression.

- Shows high flexibility and so the material can be released from undercut areas with minimum stress.

- Causes the lowest cell death count & so biocompatibility is good.

- Polysulphides are the only impression materials that can be elec- troplated.

Condensation silicones:

- Also known as room temperature (RTV) silicones.

- Highest curing shrinkage due to evaporation of ethyl alcohol byproduct. to avoid this, cast should be poured within the first 30 minutes.

- Less permanent deformation than polysulphides.

- Pleasant color and odor.

- Low tear strength.

- Hydrophobic in nature.

- Flexibility is high when compared with polysulphides. So, the impression can be removed from undercuts without distortion. Has a limited shelf life because of oxidation of the tin component.

- Handling latex globes is contraindicated.

Addition silicones (pseudoplastic impression materials):

- Also known as polyvinyl siloxane or vinyl poly siloxane im- precision materials.

- No volatile by-product.

- Lowest curing shrinkage and lowest permanent deformation with best dimensional stability. So casts can be poured after several hours.

- Extremely hydrophobic.

- Shows the least setting time of all the elastomeric impression materials.

- Handling with latex gloves is not indicated because the sulfur present in the natural latex gloves inhibits the settings of the addition of silicone impression materials.

- Shows good shelf life than condensation silicones.

- Hydrophobic in nature.

- Vinyl impression materials can be disinfected by immersing in 10% hypochlorite or 2% glutaraldehyde solutions.

- Sometimes hydrogen may be evolved and may cause pinpoint voids in stone casts.

Polyether:

- First elastomer is to be developed primarily to function as an impression material. All the other materials were adapted for other uses.

- Stiffest of all elastomeric impression materials. So extremely difficult to remove from undercut areas because of the high modulus of elasticity.

- High tear strength next to polysulphides.

- Dimensionally more stable. The casts can be poured immediately or after several hours, or after several days. Pouring up the im- precision and removing the cast several times does not alter the dimensional stability of the polyether.

- Shows the highest cell toxicity and so the biocompatibility is not good.

- Hydrophilic in nature. (Note: Agar and alginate are also hydrophilic).

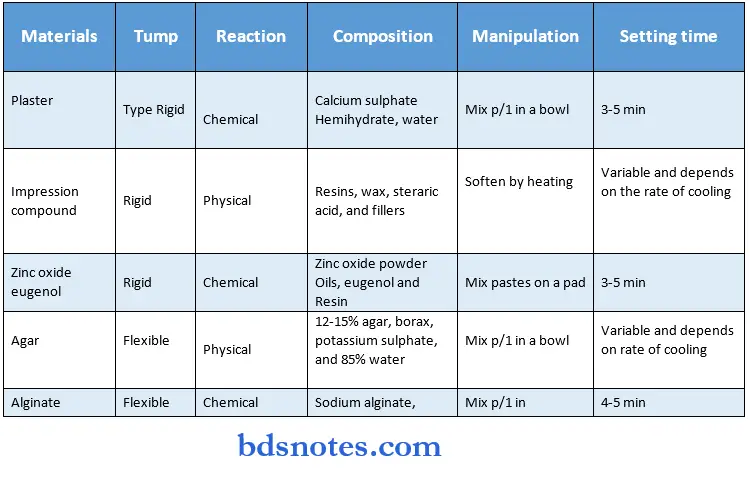

Impression Compound (ADA – 3) [SPOTTER]

Applications: For making a primary impression, individual teeth impression

Composition:

- Rosin 30%

- Copal resin 30%

- Carnauba 10%

- Rest-Stearic acid, talc, coloring agents.

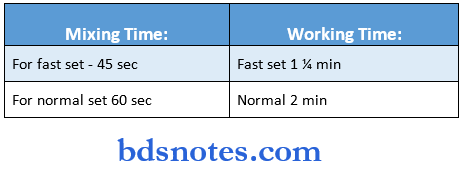

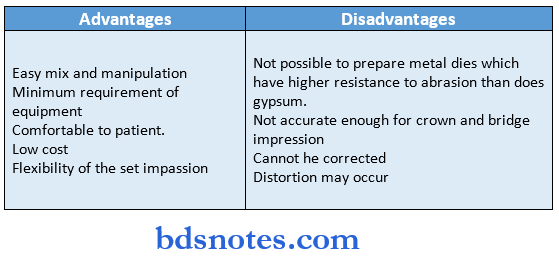

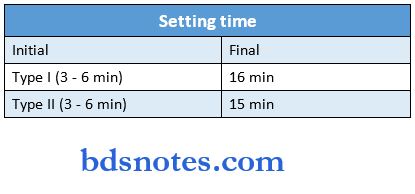

2. Alginate (ADA 18) [SPOTTER]

- Type 1 Fast setting

- Type 2 Normal setting

Applications: Impression making

- When there are undercuts in mouths with the excess flow of saliva.

- For partial denture with clasp.

- For making an impression for orthodontic and study models.

Composition:

Esters of

- Alginic acid – 15%

- CaSO4-16%

- Zinc phosphate – 4%

- K Ti fluoride

- Diatomaceous earth

- Nas PO

- Coloring and flavoring agent

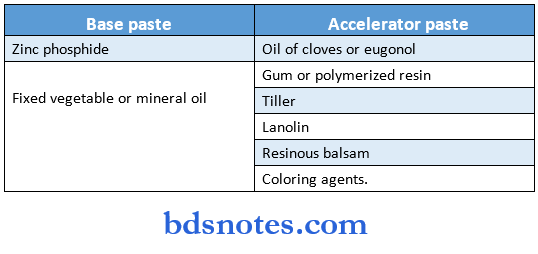

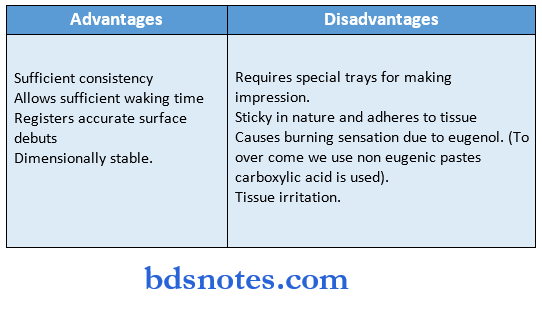

Zinc Oxide Eugenol Impression Paste (ADA 16) [SPOTTER]

- Type 1 Hard

- Type 2 Soft

Composition:

Uses:

- Cementing and Insulating medium.

- Temporary fillings

- Root canal filling material.

- Bite registration paste.

Leave a Reply