Basic Constituents And Manufacture Of Feldspathic Porcelain

- The wide variety of ceramic products in the market makes it virtually impossible to provide a single composition.

- Traditionally, porcelains were manufactured from a mineral called feldspar. These porcelains are referred to as feldspathic porcelains.

- As technology improved other ceramic systems were introduced, like core porcelains, glass ceramics, etc.

- The composition of these differs from the traditional feldspathic porcelains.

Read And Learn More: Basic Dental Materials Notes

Basic Structure

Most current ceramics consist of two phases.

- Glassy phase—acts as the matrix

- Crystalline phase—dispersed within the matrix and improves strength and other properties of the porcelain, for example, quartz, alumina, spinel, zirconia, etc.

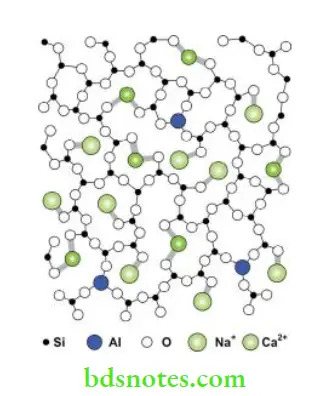

- The structure of porcelain is similar to that of glass. The basic structure, therefore, consists of a three-dimensional network of silica (silica tetrahedra). The pure glass melts at too high a temperature for dental use. Adding certain chemicals lowers the melting temperature by disrupting the silica network.

- The glass obtains porcelain-like qualities when the silica network is broken by alkalies like sodium and potassium. This also lowers the fusion temperature. These chemicals are known as glass modifiers or faxes. Other substances which act as glass modifiers are alumina (Al2O3) and boric oxide (B2O3).

- Boric oxide forms its own separate network between the silica network. Adding certain opacifiers reduces the transparency and completes the transformation to dental porcelain.

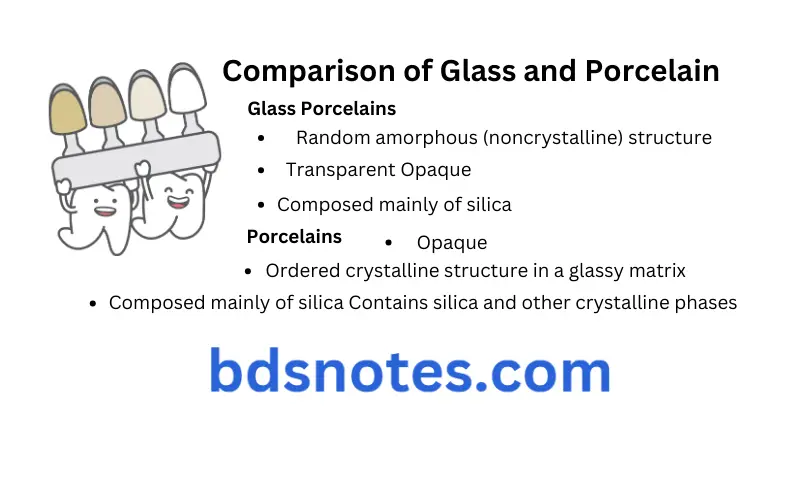

Comparison of Glass and Porcelain

- Glass Porcelains

- Random amorphous (noncrystalline) structure

- Transparent Opaque

- Composed mainly of silica

- Porcelains

- Ordered crystalline structure in a glassy matrix

- Opaque

- Composed mainly of silica Contains silica and other crystalline phases

Basic Constituents

The basic constituents of feldspathic porcelains are

- Feldspar – Basic glass former/matrix

- Kaolin – Green stage binder

- Quartz – Filler and opacifier

- Alumina – Additional glass former and fix

- Alkalies – Glass modifiers (fix)

- Color pigments – Modifis color

- Opacifiers – Reduces transparency

Feldspar

- It is a naturally occurring mineral and forms the basic constituent of feldspathic porcelains. Most of the components needed to make dental porcelain are found in feldspar. It thus contains potash (K2O), soda (Na2O), alumina (Al2O3), and silica (SiO2).

- It is the basic glass former. When fused at high temperatures (during manufacture) it forms a feldspathic glass containing potash feldspar (K2O.Al 2O3.6SiO2) or soda feldspar (Na2O.Al2O3.6SiO2).

- Pure feldspathic glass is quite colorless and transparent. As explained earlier, various glass modifiers and opacifiers are added to alter its sintering temperature, viscosity, thermal coefficient of expansion (CTE), and appearance.

Kaolin

- Kaolin also called china clay, is a white clay-like material (hydrated aluminum silicate). Kaolin is named after the hill in China (Kao-ling) from which it was mined for centuries.

- It acts as a binder when wet, helping to shape the green porcelain. It also gives opacity to the mass. Some manufacturers use sugar or starch instead of kaolin.

Quartz

Quartz is a form of silica. Ground quartz acts as a refractory skeleton, providing strength and hardness to porcelain during firing. It remains relatively unchanged during and after firing.

Alumina

- Aluminum oxide (alumina) replaces some of the silica in the glass network. It gives strength and opacity to the porcelain.

- It alters the softening point and increases the viscosity of porcelain during firing.

- Another glass former is a boric oxide (B2O3) which forms its own glass network (also called lattice) interspersed between the silica network (lattice).

Glass modifiers

- Alkalies such as sodium, potassium, and calcium are called glass modifiers.

- Glass modifiers lower the fusion temperature and increase the flow of porcelain during firing.

- They also raise the CTE (important in metal ceramics).

- However, too high a concentration of glass modifiers is not good for the ceramic because

-

- It reduces the chemical durability of the ceramic

- It may cause the glass to devitrify (crystallize)

Opacifirs

- Since pure feldspathic porcelain is quite colorless, opacifiers are added to increase its opacity in order to simulate natural teeth.

- Oxides of zirconium, titanium, and tin are commonly used opacifiers.

Color modifiers

- Natural teeth come in a variety of shades. In addition, it acquires external stains from the environment.

- Thus, color modifiers are required to adjust the shades of the dental ceramic. Various metallic oxides provide a variety of colors, for example, titanium oxide (yellow-brown), nickel oxide (brown), copper oxide (green), manganese oxide (lavender), cobalt oxide (blue), etc.

- They are fused together with regular feldspar and then reground and blended to produce a variety of colors.

Other Specialized Porcelains

Glazes

- It is a special type of colorless porcelain applied to the surface of the completed ceramic restoration to give it a smooth finish as well as increase the life of the restoration.

- Obviously, they do not contain opacifiers. They must also have a lower fusion temperature and therefore must contain a lot of glass modifiers.

- This also makes them somewhat less chemically durable.

Stains

- They are porcelain powders containing a high concentration of color modifiers (as described previously).

- They too have a lower fusion temperature made possible by an increased content of glass modifiers. Stains are used to provide individual color variation in the finished restoration.

Opaquer Porcelains

- It is a specialized type of porcelain which is used to conceal the metal core in PFM (metal-ceramic) restorations. It is the first layer applied before the addition of regular porcelain.

- Obviously, it contains a high concentration of opacifiers. Some amount of color modifiers are also added.

Reinforced Core Ceramics

- The low strength of traditional feldspathic porcelain prompted research into methods of reinforcing ceramics.

- The first reinforced ceramic (alumina reinforced) was introduced by McLean and Hughes in 1965. Subsequently, other materials and techniques were introduced.

- Among the strongest of core ceramics currently available are the machined zirconia cores.

Manufacture

- Traditionally, porcelain powders are manufactured by a process called fritting. Various components are mixed together and fused.

- While it is still hot, it is quenched in water. This causes the mass to crack and fracture, making it easier to powder it.

- The fruit is ground to a fine powder and supplied to the consumer in bottles.

- Most of the chemical reaction takes place during the manufacture (pyrochemical reaction).

- During subsequent firing in the dental laboratory, there is not much of a chemical reaction).

- The porcelain powder simply fuses together to form the desired restoration.

Porcelain/Ceramic Systems

- Currently, various ceramic systems exist which can be quite confusing to the dental student.

- The entire restoration may be made of just one type of porcelain (for example. an inlay machined from a single block of ceramic) or it may be layered with different types of porcelain.

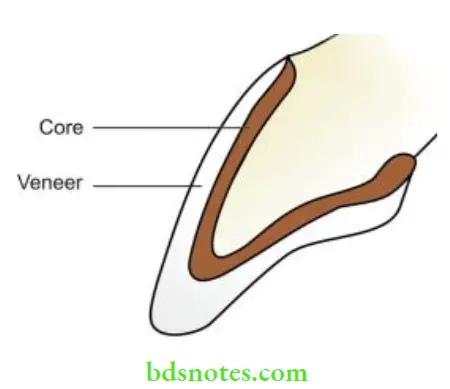

- Many crowns and FDPs are fabricated as layered restorations. A layered restoration can be divided into 2 basic parts.

- Core (or substructure)

- Veneer (outer layer).

1. Core

- The core provides support and strength for the crown.

- Early crowns were constructed entirely of a single type of feldspathic porcelain (for example PJC).

- In 1965 McLean demonstrated improved strength in crowns layered over an aluminous core.

- Since then other core materials and techniques have been introduced.

- The core functions as a supporting frame. Freshly mixed porcelain is like wet sand.

- It needs to be supported while it is being condensed and built up.

- The core is therefore usually constructed first.

- The rest of the restoration is built up onto the core.

- With metal-ceramic crowns, the metal coping or frame takes the role of the ceramic core.

- They provide support and reinforcement. Examples of core materials currently available are alumina, spinel, zirconia, etc.

2. Veneer

- The core is usually dense and opaque and generally unesthetic.

- The esthetics is improved by filling additional layers of ceramic known as veneer porcelains.

- The core is veneered with various layers of specialized porcelains called dentin, enamel, cervical and translucent.

- It can also be internally and externally (surface) stained to mimic natural teeth color and finally glazed.

Leave a Reply