Denture Resins And Polymers

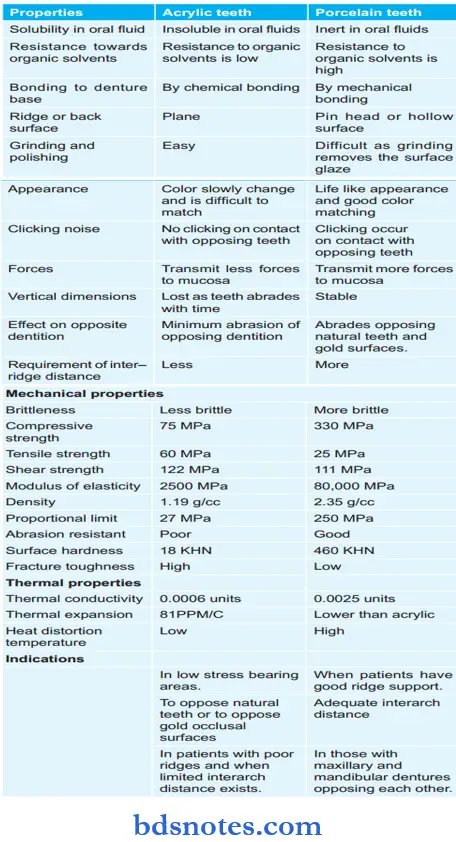

Question 1. Write a short note on acrylic and porcelain teeth

Answer:

Question 2. Write a short note on the stages of polymerization.

Or

Write a brief on the stages of polymerization.

Or

Write in brief on the polymerization of the resin.

Or

Describe the physical and chemical stages in polymerization.

Answer:

Polymerization: The term polymerization refer to a series of chain reaction by which a macromolecule or polymer is formed from a single molecule known as monomer. Polymerization is a repetitive intermolecular reaction that is capable of proceeding indefinitely.

Stages of Polymerization:

- Chemical Stages: Occurs in four stages

- Induction

- Propagation

- Chain transfer

- Termination.

1. Induction:

The induction or initiation period is the time during which the molecules of the initiator become energized or activated and start to transfer the energy to the monomer.

There are three induction systems for dental resins:

- Heat activation: Most denture resins are polymerized by this method, e.g. the free radicals liberated by heating benzoyl peroxide will initiate the polymerization of methyl methacrylate monomer.

- Chemical activation: This system consists at least two reactants, when mixed they undergo a chemical reaction and liberate free radicals, e.g. benzoyl peroxide and an aromatic amine (Dimethyl-p-toluidine).

- Light activation: Photons of light energy activates the inhibitor to generate free radicals. For example, camphor quinone and an amine will react to form free radicals when they are irradiated with visible light.

2. Propagation:

The resultant free radical monomer complex, then act as a free radical center when it approaches another monomer to form a dimer which also becomes a free radical, this process of polymerization continues by forming new active center.

- 2H2C = CH2 + CH2 = CH2 → 2H2C — CH2 — CH2 — CH2

This process continues very rapidly till all monomer are exhausted.

3. Chain transfer: Also called “Energy transfer”, here the active state in transferred from an activated radical to an inactive molecule, and a new nucleus of growth is created.

4. Termination: The chain reaction can be terminated either by direct coupling or by the exchange of a hydrogen atom from one growing chain to another.

Physical Stages of Polymerization:

- Stage I: Wet Sand Stage: Polymer gradually settles into the monomer forming a fluid, incoherent mass.

- Stage II: Sticky Stage:

- Monomer attacks the polymer by penetrating into the polymer.

- The mass is sticky and stringy (cobweb-like) when touched or pulled apart

- Stage III: Dough or Gel Stage:

- As the monomer diffuses into the polymer, it becomes smooth and dough-like.

- It does not adhere to the walls of the jar. It consists of undissolved polymer particles suspended in a plastic matrix of monomer and dissolved polymer.

- The mass is plastic and homogenous and can be packed into the mold at this stage.

- Stage IV: Rubbery Stage:

- Monomer disappears by further penetration into the polymer for evaporation.

- The mass is rubber-like, non-plastic, and can not be moulded.

- Stage V: Stif Stage: Formal mass is totally unworkable and should be discarded.

Question 3. Give the ideal requirements of denture base materials.

Or

How far acrylic resin fulfill those requirements?

Or

What are the ideal requirements of denture base materials? How far does polymethyl methacrylate meet these requirements?

Answer:

The most commonly used materials for the fabrication of denture bases are polymers such as polymethyl methacrylate or acrylic resin.

Requirements of an Ideal Denture Base:

The Material Should:

- Be tasteless, odorless, non-toxic, and non-irritant to the oral issue.

- Be aesthetically satisfactory, i.e. should be transparent or translucent and easily pigmented, the color should be permanent.

- Be dimensionally stable. It should not expand, contract or warp during processing and subsequent use by the patient.

- Have enough strength, resilience, and abrasion resistance.

- Be insoluble and impermeable to oral fluids.

- Have a low specific gravity and light in weight.

- Tolerate temperature well above the temperature of any hot foods or liquids taken in the mouth without undue softening or distortion.

- Be easy to fabricate and repair.

- Have good thermal conductivity.

- Be radiopaque (so that broken denture fragments can be detected by X-rays if accidentally aspirated or swallowed and also to examine the extensions of the resin restoration

in a tooth). - When used as a filling material it should bond chemically with the tooth.

- Have a coefficient of thermal expansion which match that of tooth structure.

- Be economical.

Acrylic Resin Of Ideal Denture Base:

Popularity of polymethyl methacrylate occurs from the fact that the material exhibits favorable working characteristics, has acceptable physical, mechanical, and aesthetic properties, and is easy to fabricate with inexpensive equipment.

- Taste and odor: Completely polymerized acrylic resin is tasteless and odorless. On the other hand, poorly made dentures with a high amount of porosity can absorb food and bacteria, resulting in an unpleasant taste and odor.

- Esthetics: It is a clear transparent resin, which can be pigmented (colored) easily to duplicate the oral tissue. It is also compatible with dyed synthetic filers thus esthetics is acceptable.

- Strength: These materials are typically low in strength. However, they have adequate compressive and tensile strength for complete or partial denture applications.

- Modulus of Elasticity: They have sufficient stiffness (2400 MPa) for use in complete and partial dentures.

- Dimensional stability: A well-processed acrylic resin denture has good dimensional stability. The processing shrinkage is balanced by the expansion due to water sorption.

- Solubility: Acrylic is virtually insoluble in water and oral fluids.

- Stability to heat: Polymethyl methacrylate is chemically stable to heat up to a point. It softens at 125°C.

- Radiopacity: There are instances of broken pieces of dentures being aspirated or swallowed. Radiopacity is a desirable property to enable easy location of fragments.

- Most denture base materials are radiolucent. Radiopacity is obtained by adding heavy metal salts such as bismuth or uranyl at a concentration of 10 to 15%

Thermal properties:

- Stability to heat: Polymethyl methacrylate is chemically stable to heat up to a point. It softens at 125°C. However, above this temperature, i.e. between 125°C and 200°C it begins to depolymerize. At 450°C, 90% of the polymer will depolymerize to monomer.

Thermal conductivity: They are poor conductors of heat and electricity. This is undesirable because patients wearing acrylic complete dentures often complain that they cannot feel the temperature of food or liquids they ingest, thus reducing the pleasure. Replacing the palatal portion with metal is one solution because the metal is a better conductor of heat.

- Coefficient of thermal expansion:

- These materials have a high coefficient of thermal expansion (CTE).

- The CTE for polymethyl methacrylate resin is 81 × 106/°C.

- The addition of filers reduces CTE.

- Heat distortion temperature: This is the measure of the ability of a plastic to resist dimensional change when loaded under heat. It is measured by observing the temperature at which a specimen under 1.8 MPa load defects 0.25 mm.

- Heat distortion temperature for PMMA — 71 to 91°C.

- Heat distortion temperature for vinyl resin — 54 to 77°C.

- Distortion is of concern during procedures like the repair or polishing of dentures.

- The temperature should be kept low to avoid distortion.

- Color stability: Heat-cure acrylic resins have good color stability. The color stability of self-cure resin is slightly lower.

- Biocompatibility: Completely polymerized acrylic resins are biocompatible.

- Adhesion: The adhesion of acrylic to plastic denture teeth is good chemical adhesion.

- Shelf life: Acrylic resins dispensed as powder and liquid have the best shelf-life.

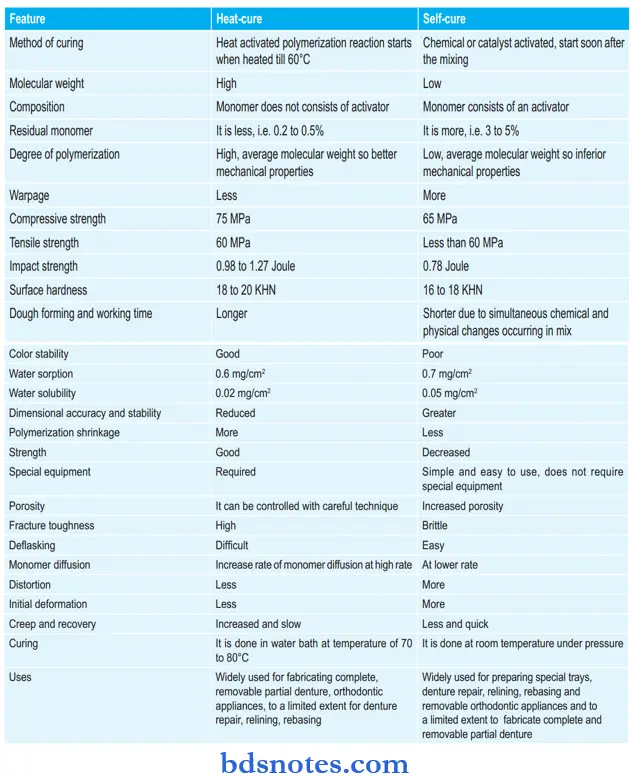

Question 4. Write notes on heat-curing vs self-curing acrylic resin.

Or

Compare and contrast self-cure and heat-cure denture base resin.

Or

Write the difference between cold-cure and heat-cure acrylic resin

Or

Answer:

Comparison Of Heat And Self – Cured Resins:

Question 5. Describe briefly the polymer-monomer reaction.

Answer:

Or

Write short notes on the physical stages of polymerization.

Answer:

Stages Occur during the Mixing of Polymer and Monomer:

After mixing, the material goes through various physical states. No polymerization reaction takes place during these stages. Plastic dough is formed by a partial solution of the

polymer in the monomer.

Physical Stages

- Stage I: Wet Sand Stage:

- Polymer gradually settles into the monomer forming a fluid, incoherent mass.

- Mix exhibits a sandy consistency during this stage.

- Stage II: Sticky/Stringy Stage:

- Monomer attacks the polymer by penetrating into the polymer.

- The mass is sticky and stringy (cobweb-like) when touched or pulled apart.

- Stage III: Dough or Gel Stage:

- As the monomer diffuses into the polymer, it becomes smooth and dough-like.

- It does not adhere to the walls of the jar.

- It consists of undissolved polymer particles suspended in a plastic matrix of monomer and dissolved polymer.

- The mass is plastic and homogenous and can be packed into the mold at this stage.

- Stage IV:

- Rubbery Stage Monomer disappears by further penetration into the polymer for evaporation.

- The mass is rubber-like, non-plastic, and cannot be moulded.

- Stage V: Stif Stage Formal mass is totally unworkable and should be discarded.

Question 6. Write a short note on the curing of a denture base material.

Answer:

Curing (Polymerization): After final closure, the flask is kept at room temperature for 30 to 60 minutes (bench curing).

Purpose of Bench Curing:

- Permits an equalization of pressure throughout the mold.

- It allows time for more uniform dispersion of monomer throughout the mass of dough, since the last material added is usually drier than the fist added to the flask.

- If resin teeth are used, it provides a longer exposure of resins teeth to the monomer in the dough producing a better bond of the teeth with the base material

Curing:

- After bench curing, the flask is placed in a cold water bath.

- It is then heated slowly.

- As the temperature of the water bath increases heat starts to conduct inside.

- When the temperature of the acrylic dough reaches about 60°C, benzoyl peroxide (initiator) is decomposed to produce two free radicals.

- Each free radical rapidly reacts with an available monomer molecule to initiate polymerization.

- The polymerization reaction propagates with the liberation of heat (12.9 kcal/mole) because the polymerization reaction is exothermic.

- Since the acrylic resin and stone are poor thermal conductors of heat, the heat of the reaction cannot be dissipated.

- Therefore, the temperature of the resin increases well above the temperatures of surrounding materials and may increase to a value even up to about l20°C–130°C.

- This temperature is greater than the boiling point of a monomer such as 100.8°C.

- So at these temperatures, the residual monomer will boil and the monomer vapor enclosed by hard polymer and a porous structure will be created.

- This type of porosity will not be seen at the surface of the denture base because exothermic heat can be conducted away from the surface of the denture into the investing medium and the temperature in the thin region is not likely to rise above the boiling point of the monomer.

- These do not show gaseous porosity but their heat of reaction is passed onto the interior portions of the dough.

- It is here the gaseous porosity is seen. In other words, it occurs away from the source of heat, i.e. at the center of a thick portion of the denture when heat cannot be conducted away with sufficient rapidity and the temperature of the resin is likely to cross 100.8°C.

Curing Cycle:

The curing cycle is the technical name for the heating process employed to control the initial propagation of polymerization in the denture mold.

For heat-cure acrylic resins, the curing cycle used is of great importance in the quality of the final denture since the polymerization reaction is strongly exothermic.

The following two methods have been suggested to obtain non-porous denture:

- Slow curing cycle.

- Fast curing cycle.

1. Slow curing cycle:

- It involves the processing of denture base resin in a constant temperature water bath at 74°C for 8 hours or longer with no terminal boiling treatment.

- The lower the constant temperature, the longer the time is needed for curing.

- If the bulk of the acrylic is more, better to cure at low temperatures and a longer time is required for curing.

- Slowly raise the temperature of the water bath to about 74°C in about half an hour and maintain the temperature constant for 8 hours or more.

2. Fast Curing Cycle

It involves heating the resin at 74°C for approximately 1½ to 2 hours and then increasing the temperature of the water bath to 100°C and processing for one hour or more.

- Slowly raise the temperature of the water bath to about 74°C in about half an hour and maintain the temperature constant for 1½ hours.

- During this time, more than 95% of monomer is converted to polymer.

- In order to reduce the amount of residual monomer or to ensure complete polymerization, the water in the bath can be boiled for about 1 hour.

- This technique enables a denture to be fabricated in a shorter

time.

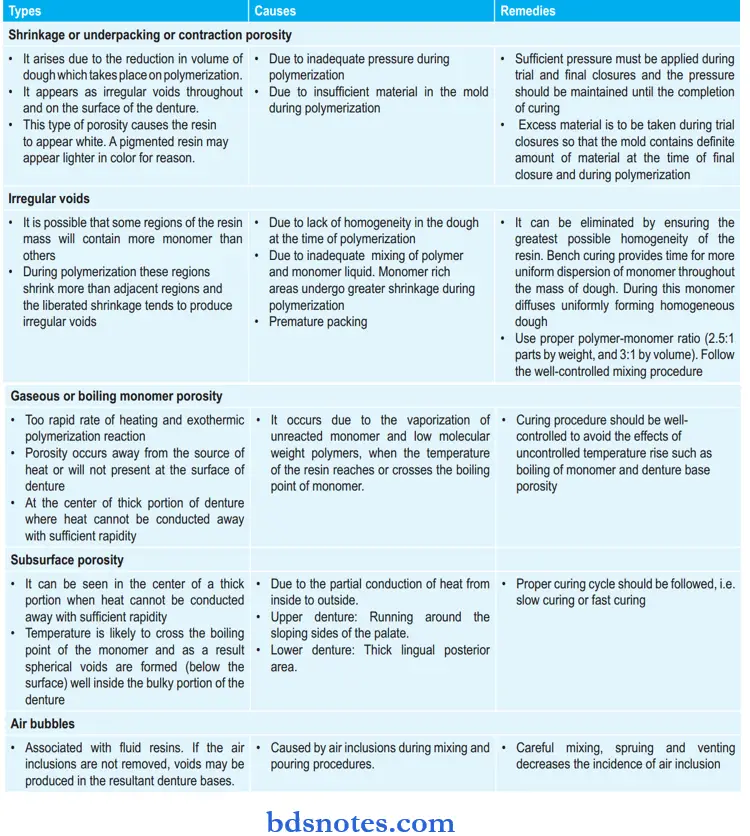

Question 7. Write a short note on porosities in the acrylic denture base.

Or

Write a short note on porosities in heat-cure acrylic resin.

Or

Write a short note on porosity in denture base resin.

Or

Write Causes of porosity in denture

Answer:

Porosity means the presence of voids or pores within a structure.

When the porosities are present on the surface of an acrylic denture base, it:

- Makes the appearance of a denture base unsightly.

- Proper cleaning of the denture is not possible, thus oral hygiene suffers.

- Weakens the denture base.

Types Of Acrylic:

Porosities are classified as:

On their Presence on Denture Base Surface:

- Internal porosity:

- Shrinkage or underpacking or contraction porosity

- Irregular voids

- Gaseous or boiling monomer porosity

- Subsurface porosity

- Air bubbles

- External porosity

Based Upon the Causes:

- Gaseous

- Granular

- Contraction

- Air inclusion

Description of Properties:

Internal Properties:

External porosity:

It can occur due to two reasons:

- Lack of homogeneity: If the dough is not homogenous at the time of polymerization the portion containing more monomer will shrink that localized shrinkage results in voids. Resin appear white.

- Avoided by: Using proper powder/liquid ratio and mixing it well. Packing should be done in dough stage.

- Lack of adequate pressure: Lack of pressure during polymerization or inadequate amount of dough in mould during fial closure cause bubble which are not spherical.

- Avoided by: Using adequate amount of dough. Also check for excess or flsh during trial closure. Flash is indicative of adequate material.

Question 8. Answer briefl on denture soft liner material.

Write a short note on soft liners.

Or

Write a short note on short denture liners

Answer:

Soft liners are soft cushion like liners which are given to the denture base to absorb some of the energy produced by masticatory impact and to distribute the forces of mastication more evenly.

Types Of Denture liners:

- Short-term soft liners (ISO 10139 Part 1)

- Long-term soft liners (ISO 10139 Part 2)

1. Short-term Soft Liners:

They are also known as temporary liners.

Composition Of Short-term Soft Liner:

- Powder:

- Prepolymerized spheres of PMMA

- Benzyol peroxide—initiator

- Color pigments

- Inorganic salts

- Liquid:

- Methyl methacrylate

- Dibutyl phthalate (50 to 60%)—plasticizer

- Tertiary amine—activator

- Hydroquinone—inhibitor

- Liquid: Mixture of ethyl glycol + An aromatic ester, i.e. butyl glycolate or dibutyl phthalate.

Indications Of Short-term Soft Liner:

- For relining an ill fitting denture which allows the tissues to return back to normal at which point a new denture can be made.

- As functional impression material.

Advantages Of Short-term Soft Liner:

- They have a high peel strength

- They are rupture resistant.

Disadvantages Of Short-term Soft Liner:

- They have poor resistance.

- They lose their plasticity in time.

Manipulation Of Short-term soft line:

- The denture base is relieved on the tissue surface.

- Mix powder and liquid together to form a gel and place it on the tissue surface of the denture and insert it in the mouth.

- Gel flows readily to fil the space between the denture base and oral tissue.

2. Long-term Soft Liner:

They are also known as permanent soft liners. This is because they are used for extended periods from 6 months to 5 years.

Types Of Soft Liner:

- Plasticized acrylic resin

- Plasticized vinyl resin

- Silicone rubbers

- Polyphosphazine

Indications Of Soft Liner:

- In patients having highly resorbed or atrophied ridges.

- In patients having bruxism.

- For relining the prosthesis which is used to restore maxillofacial defects.

- To restore congenital or acquired oral defects.

- In patients suffring from xerostomia.

Advantages Of Soft Liner:

- Abused tissues healed quickly.

- Patients adapt to dentures quickly.

- This creates the possibility of an immediate denture following extraction.

Disadvantages Of Soft Liner:

- Poor resistance to wear.

- With time plasticizers leach out making them hard.

- Color stability is poor.

- Rough surface harbors certain microorganisms.

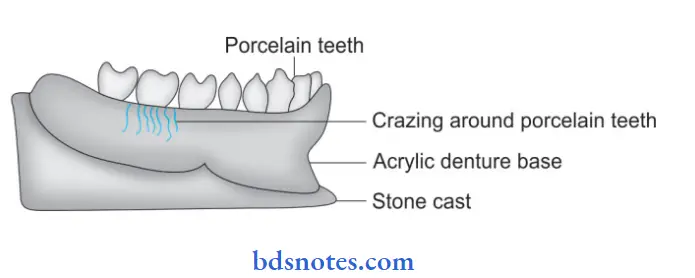

Question 9. Write a short note on crazing.

Answer:

Crazing is the formation of very fine microcracks or flaws on the surface of the denture.

Mechanism of Formation:

It occurs due to the mechanical separation of individual polymer chains on the application of tensile stresses. Crazing starts from the surface of resin and is oriented at a right angle to tensile force. Microcracks form in this manner subsequently progress internally.

The appearance of Crazing:

In transparent resins, appearance is hazy or foggy while in tinted resin it is white in appearance.

Effects of Crazing:

- It decreases the strength of the denture leading to the fracture of the denture base.

- The esthetic qualities of dentures are reduced.

- It leads to the collection of food and debris and denture become unhygienic.

Causes For Occurrence Of Crazing:

- As dentures get subjected to cycles of frequent drying and water sorption it leads to crazing

- This happens when the patient frequently removes the denture and dries it out which leads to induction of sufficient tensile stresses which causes crazing.

- Due to the difference in thermal expansion between porcelain and acrylic resin, crazing occur at neck of porcelain teeth.

- At the time of denture repair when the monomer contact with cured acrylic resin of broken fragments microcracks may appear.

- Crazing can also result due to solvent action.

- It occur due to prolonged contact with liquids, i.e. ethyl alcohol.

Prevention of Crazing

- By use of improved acrylic resin teeth and cross-linked denture-based resins.

- By avoiding porcelain teeth.

- By using tin foil separating medium.

- By using metal molds.

Question 10. Write a short note on tissue conditioners.

Or

Write the short answer on tissue conditioners.

Answer:

Tissue conditioners are for the short time use only, i.e. for few days only. Most commonly PMMA soft lining materials are used on the tissue surface of dentures to act as tissue conditioner.

Composition Of tissue conditioners:

- Powder: Polymethyl methacrylate polymer beads

- Liquid: Ethyl alcohol—solvent; Butyl phthalate/butyl glyco- late—plasticizer

Properties Of tissue conditioners:

- Tensile strength is 0.80 to 0.83 MPa

- Percentage elongation is 150 to 300%

- Hardness is 30 to 95 KHN

- Tear resistance is 29 to 260 N/cm.

Manipulation Of tissue conditioners:

- The denture base is relieved on the tissue surface.

- Mix powder and liquid together to form a gel and place it on the tissue surface of the denture and insert it in the mouth.

- Gel flows readily to fil the space between the denture base and oral tissue.

Indications Of tissue conditioners:

- For conditioning abused basal tissues before fabrication of denture.

- As reline material in surgical obturator.

- For stabilizing, enhancing retention and comfort of temporary denture base at the time of recording maxillomandibular relations.

- As functional impression material.

Advantages Of tissue conditioners:

- It has ideal viscoelasticity

- It provides a good fit to dentures

- A chairside application is present.

Disadvantages Of tissue conditioners:

- It has low cohesive strength

- It has alcohol which act as irritant.

Care and Maintenance

- Tissue conditioners should not be cleaned by scrubbing with a hard brush in order to prevent tearing of the material.

- The use of soft brush under running water is recommended.

- Their biggest flaw is that they are so easily misused

- Their longevity against wear is very limited and they tend to harden and roughen within 4 to 8 weeks due to the loss of plasticizer.

- Hence, they require close observation.

Question 11. Write a short note on the compressive molding technique.

Or

Compression molding technique.

Answer:

The compression molding technique is also known as the pressure packing technique. Heat-activated denture bases are commonly processed by this technique.

Steps in Compression Molding Technique:

- Preparation of the waxed denture pattern: The structure to be created is fist constricted in wax; the wax portion will be replaced with acrylic.

- Preparation of split mold: The waxed denture is invested in a dental flask with dental stone or plaster by three-pour technique. After the stone or plaster sets, it is dewaxed by placing it in a hot water bath. Removal of the wax leaves an empty space or creates mold. Mold is flashed further with hot water and mild detergent to remove any wax residue and is cleaned.

- Application of separating medium: A tin foil substrate, i.e. cold mold seal is applied both on the investment and the cast. Generally, two coats in succession should be applied.

- Mixing of powder and liquid: Polymer-monomer proportion 3:1 by volume or 2:1 by weight. The measured liquid is poured into a clean, dry mixing jar. The powder is slowly added allowing each powder particle to become wetted by monomer. The mixture is then stirred and allowed to stand in a closed container. Once the material reaches dough stage it is kneaded by a wet cellophane sheet.

- Packing: The powder liquid mixture should be packed into the mold space at the dough consistency and the flask is reassembled.

- Trial closure: Mold should be overfilled by the acrylic which should be removed by trial closures till no flesh is evident. A sharp scalpel is preferred to cut the flesh.

- Now flask is transferred to a hydraulic bench press which maintains the flask under compression for half an hour for bench curing during which the monomer completely dissolves the polymer. For curing to get complete, flask should be placed in a controlled water bath.

Question 12. Write a note on the curing cycle.

Or

Write briefly on curing cycles in acrylic resin.

Or

Describe briefly curing cycles of heat-cure resi

Answer:

The heating process used to control polymerization is called as curing or polymerizing cycle. This process should be well controlled to avoid effect of uncontrolled temperature rise, such as boiling of monomer and denture base porosity.’

The curing cycle is the technical name for the heating process employed to control the initial propagation of polymerization in the denture mold. For heat-cure acrylic resins, the curing cycle used is of great importance in the quality of the final denture since the polymerization reaction is strongly exothermic.

The following two methods have been suggested to obtain non-porous dentures:

- Slow curing cycle.

- Fast curing cycle.

1. Slow Curing Cycle:

- It involves the processing of denture base resin in a constant temperature water bath at 74°C for 8 hours or longer with no terminal boiling treatment.

- The lower the constant temperature, the longer the time is needed for curing.

- If the bulk of the acrylic is more, better to cure at low temperatures,s and longer time is required for curing.

- Slowly raise the temperature of the water bath to about 74°C in about half an hour and maintain the temperature constant for 8 hours or more.

2. Fast Curing Cycle:

- It involves heating the resin at 74°C for approximately 1½ to 2 hours and then increasing the temperature of the water bath to 100°C and processing for 1 hour or more.

- Slowly raise the temperature of the water bath to about 74°C in about half an hour and maintain the temperature constant for one and a half hours.

- During this time, more than 95% of monomer is converted to polymer.

- In order to reduce the amount of residual monomer or to ensure complete polymerization, the water in the bath can be boiled for about 1 hour.

- This technique enables a denture to be fabricated in a shorter time.

Question 13. Give composition and mode of polymerization of denture base acrylic resin.

Or

Give the composition of denture base acrylic resin.

Or

Composition of heat-cure and cold-cure acrylic resin

Answer:

Composition Of acrylic resin:

Heat Activated:

- Available as powder and liquid:

- The powder may be transparent or tooth-colored or pink (to stimulate the gums some even contain red fiers to duplicate blood vessels).

- The liquid is supplied in tightly sealed amber-colored bottoms (to prevent premature polymerization by light or UV radiation on storage).

- Liquid:

- Methyl methacrylate – Plasticizes the polymer

- Dibutyl phthalate – Plasticizer

- Glycol dimethacrylate (1–2%) – Cross-linking agent

- Hydroquinone (0.006%) – Inhibitor-prevents setting.

- Powder:

- Polymethyl methacrylate and another copolymer 5%

- Polymethyl methacrylate beads – Major component

- Ethyl or methacrylate (5%) – Copolymers improve properties

- Benzoyl peroxide – Initiator

- Compounds of mercuric – Dyes (color pigments) sulfide, cadmium sulfide, etc

- Zinc or titanium oxide – Opacifirs

- Dibutyl phthalate – Plasticizer

- Fillers, inorganic particles like – Improves physical glass fiers, zirconium silicate, properties like alumina, etc. stiffness

- Dyed synthetic nylon or – Stimulate small acrylic fibers capillaries

Chemically Activated Denture Base Resin

Composition Of Base Resin:

- Liquid:

- Methyl methacrylate – Dissolves/plasticizes/ monomer polymer

- Dimethyl-p-toluidine – Activator

- Dibutyl phthalate – Plasticizer

- Glycol methacrylate – cross-linking agent.

- Hydroquinone (0.006%) – Inhibitor

- Powder :

- Poly (methyl methacrylate) – Dissolved by and other copolymer − 5% monomer to form dough

- Benzoyl peroxide – Initiator

- Compounds of mercuric sulfide, cadmium sulfide – Dyes

- Zinc or titanium oxide – Opacifirs

- Dibutyl phthalate – Plasticizer

- Dyed organic filers – For esthetics and inorganic particles like glass fibers or beads table

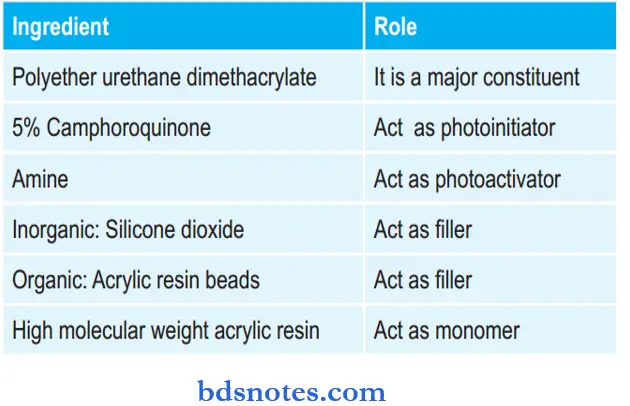

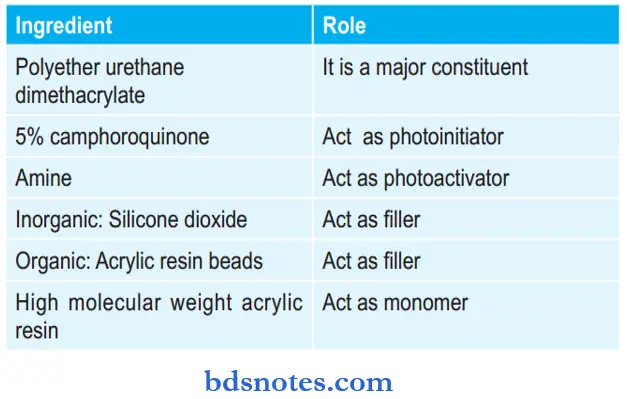

Composition Of Light Activated Acrylic Resin:

Mode of Polymerization of Denture Base Acrylic Resin:

There are three types of modes of polymerization of denture base acrylic resin, i.e.

- Heat Activated:

- Here the mode of polymerization is by application of external heat for activation of polymerization reaction which is provided by water bath or by microwave.

- Heat-activated resins are available in powder and liquid form.

- Chemical Activated:

- Here the mode of polymerization is by means of chemicals.

- In this polymerization reaction starts as soon as powder and liquid components are mixed together.

- Here activation of initiator benzoyl peroxide is done by chemical tertiary amine dimethyl-p-toluidine.

- Light Activated:

- Here the mode of polymerization is blue light of wavelength 400 to 500 nm.

- So as camphor quinone and organic amine come in contact with blue light of wavelength 400 to 500 nm they generate free radicals.

- This activation of the photoinitiator initiates the polymerization reaction.

- Light curing chamber consists of a rotating table over which the denture is placed so that it is exposed to uniform intensity of light.

Question 14. Classify denture base resin.

Or

Describe briefly denture base materials.

Or

Classification of Denture base Materials

Or

Write about the classification of denture base resin based on polymerization.

Answer:

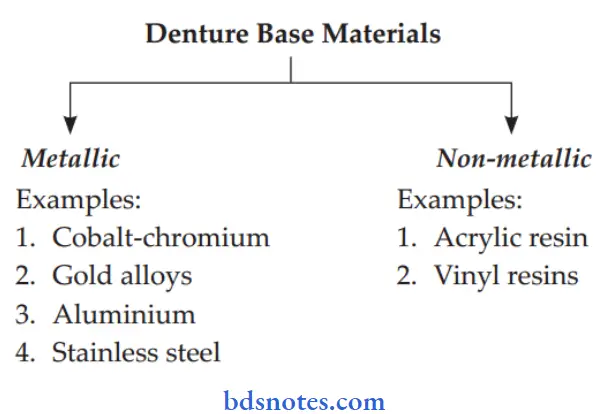

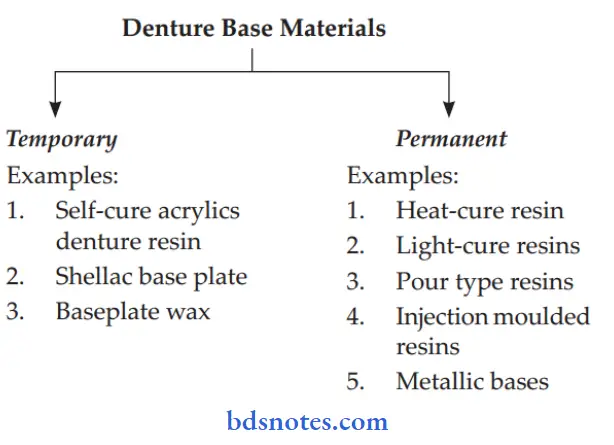

Material which is used for making denture base, is denture base materials.

Classification Of Denture Base Materials:

1.

2.

ISO 20795-1:2003 Classifiation:

- Type I—Heat polymerizable polymers

- Class 1 — Powder and liquid

- Class 2 — Plastic cake.

- Type II — Autopolymerizable polymers

- Class 1 — Powder and liquid

- Class 2 — Powder and liquid pour-type resins.

- Type III — Thermoplastic blank or powder

- Type IV — Light-activated materials

- Type V — Microwave cured materials.

Question 15. Write about use of self-cure acrylic resin.

Answer:

Uses of Self-cure Acrylic Resin:

- For making temporary crowns and FPDs.

- For denture repair, relining, and rebates.

- For making removable orthodontic appliances.

- For the construction of special trays.

- For adding a post-dam to an adjusted upper denture.

- For making temporary and permanent denture base

- For making inlay and post core patterns.

Question 16. Write a short note on self-cure acrylic resin.

Answer:

It is also known as chemically activated denture base acrylic resin or cold cure or autopolymerizing resin.

Composition Of self-cure acrylic resin:

Liquid:

- Methyl methacrylate monomer − Dissolves/plasticizes

- Dimethyl-p-toluidine − Activator

- Dibutyl phthalate − Plasticizes polymer

- Glycol methacrylate (1–2%) − Cross-linking agent

- Hydroquinone − (0.006%) Inhibitor

Powder

- Poly (methyl methacrylate) other co-polymers — 5% − Dissolved by and monomer to form a dough

- Benzoyl peroxide − Initiator

- Compounds of mercuric sulfide, cadmium sulfide − Dyes

- Zinc or titanium oxide − Opacifirs

- Dibutyl phthalate − Plasticizer

- Dyed organic filers and inorganic particles like glass fibers or beads − For esthetics

Properties Of self-cure acrylic resin:

- Its flexural strength is low.

- It has low compressive strength, i.e. 65 MPa, and low tensile strength, i.e. 60 MPa.

- Its surface hardness is 16 to 18 KHN.

- It exhibits lower dimensional changes.

- Its water sorption is 0.5 to 0.7 mg/cm2

- It has a higher solubility rate, i.e. 0.05 mg/cm2

- It has poor color stability so esthetics are compromised.

- Yellowing of material occurs.

Uses Of self-cure acrylic resin:

- For making temporary crowns and FPDs.

- For denture repair, relining, and rebates.

- For making removable orthodontic appliances.

- For the construction of special trays.

- For fabrication of temporary and permanent denture bases.

- For fabricating inlay and post-core patterns.

Advantages Of self-cure acrylic resin:

- The initial fi is good.

- Helps in repairing dentures and does not lead to warpage.

- It is easy to manipulate.

- It exhibits less shrinkage.

- Its dimensional accuracy is high.

Disadvantages Of self-cure acrylic resin:

- Color stability is inferior

- Properties are inferior compared to heat-cure acrylic resin.

- Polymerization is incomplete.

- Its flxural strength is low.

- Residual monomer leads to tissue irritation.

Question 17. Write about manipulation of heat-cure resin in detail.

Answer:

Manipulation of Heat-cure Resin:

- Mix the correct proportion of polymer and monomer, i.e. polymer/monomer ratio is 3 to 3.5/1 by volume or 2.5/1 by weight.

- First, the liquid monomer is poured in a thick, clean glass jar and then the powder is added slowly to it.

- After all powder is added the mix is stirred and vibrated thoroughly so that mechanical mixed pigments and dyes are dispensed evenly throughout the material.

- On completion of stirring, a light lid must be placed on the glass jar to prevent evaporation of the monomer.

- When polymer and monomer mix is allowed to stand in a closed container it undergoes physical changes due to the interaction of monomer to polymer.

The following are the physical stages:

- Stage I: Wet Sand Stage; Polymer gradually settles into the monomer forming a fluid incoherent mass.

- Stage II: Sticky Stage: Monomer attacks the polymer by penetrating into the polymer. The mass is sticky and stringy (cobweb-like) when touched or pulled apart.

- Stage III: Dough or Gel Stage: As the monomer diffuses into the polymer, it becomes smooth and dough-like. It does not adhere to the walls of the jar. It consists of undissolved polymer particles suspended in a plastic matrix of monomer and dissolved polymer. The mass is plastic and homogenous and can be packed into the mold at this stage.

- Stage IV: Rubbery Stage: Monomer disappears by further penetration into the polymer for evaporation. The mass is rubber–like, non-plastic, and cannot be moulded.

- Stage V: Stiff Stage: Formed mass is totally unworkable and should be discarded.

Question 18. Describe acrylic denture base materials in detail.

Answer:

Acrylic denture base materials

These are also known as polymethyl methacrylate resins.

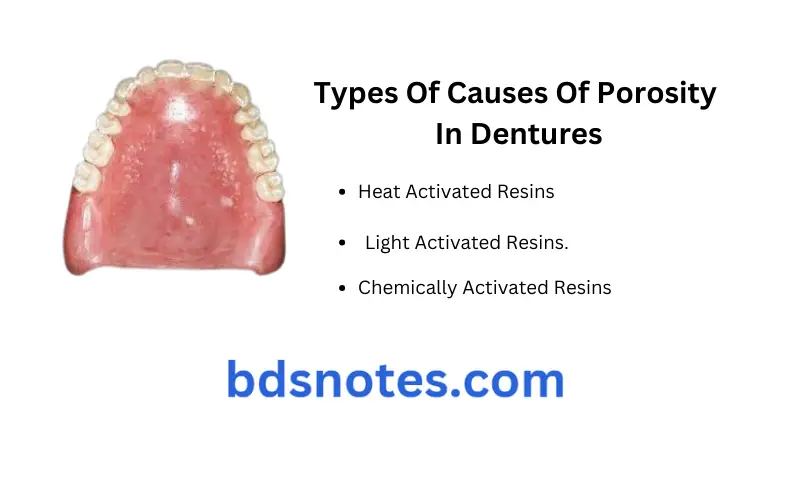

Types Of causes of porosity in dentures:

According to the method of their activation, there are three types of acrylic denture base materials, i.e.

- Heat activated resins

- Chemically activated resins

- Light activated resins.

1. Heat Activated Resins:

Polymerization Reaction: Polymerization of heat-activated resin is achieved by the application of heat and pressure. The reaction is:

Powder + Liquid + Heat → Polymer + Heat

(Polymer) (Monomer) (External) (Reaction)

Advantages Of Heat Activated Resins:

- It has low shrinkage, so it is dimensionally accurate.

- Vertical dimensions do not increase.

- The denture base is homogeneous.’

- Its impact strength is good.

Disadvantages Of Heat Activated Resins

- The cost of equipment is high.

- Problems are in mold designing

- Crazing resistance is low

- Requirement of special flask.

2. Chemically Activated Acrylic Resin:

- Polymerization Reaction:

- Polymer (Powder) + Monomer (Liquid) → Polymer + Heat

(Peroxide initiator) Amine accelerator ( Reaction)

- Polymer (Powder) + Monomer (Liquid) → Polymer + Heat

Manipulation Of Activated Acrylic Resin: Manipulation of chemically cured acrylic resin is done by following techniques:

- Sprinkle on technique

- Hand-adapting dough technique

- Fluid resin technique

- Compressing molding technique.

The most commonly used techniques for manipulation of self cure resin is sprinkle-on technique and hand-adapted dough method.

- Sprinkle-on technique:

- In this technique, both polymer and monomer are added to the cast which consists of a separating medium.

- In this powder is added to the cast and monomer is added to it till the proper thickness is achieved.

- The liquid is added to the powder with the help of a dropper.

- Hand-adapted dough technique:

- In this technique, both the powder and liquid are proportionate and mixed in a porcelain jar.

- As the mix proceeds to the dough stage, it is placed in between two glass slabs, now it is removed, and is adapted to the cast manually in the desired shape.

3. Light Activated Acrylic Resin:

They are single component system. Light-activated resin is supplied as premixed sheets or ropes packed in light-proof pouches to prevent accidental polymerization.

Composition of Light Activated Acrylic Resin:

Technique or Manipulation:

- Fabrication of denture base: As the base material is in the plastic stage, it should be adapted on the master cast. Polymerize it to hard set in the light chamber without teeth to be used as a base plate.

- Completion of denture: Attach the teeth to the base plate by additional material and the anatomy of the polished surface should be made accordingly. As sculpting is complete denture should be placed again in a light chamber for polymerization. As polymerization is overdenture should be fiished and polished.

Mode of Polymerization:

- Here the mode of polymerization is blue light of wavelength 400 to 500 nm.

- So as camphor quinone and organic amine come in contact with blue light of wavelength 400 to 500 nm they generate free radicals.

- This activation of the photoinitiator initiates the polymerization reaction.

- Light curing chamber consists of a rotating table over which the denture is placed so that it is exposed to the uniform intensity of light.

Properties Of Activated Acrylic Resin:

- The impact strength for visible light curing denture material is 13 J/m which is less than other dentures.

- Flexural strength is 80 MPa which is comparable to other resins.

- The hardness of light-activated resin is 18 KHN.

Advantages Of Activated Acrylic Resin:

- It has less porosity.

- It is light in weight.

- Its fabrication final adjustment should be done in the mouth.

- It does not produce any allergic reaction.

- It is free of methyl methacrylate.

- It is non-toxic.

- It also decreases polymerization shrinkage.

Disadvantages Of Activated Acrylic Resin:

- It should not be packed, so need artistic skills.

- Its procedure is time-consuming.

- It is very technique sensitive.

Question 19. Write a short note on separating media.

Or

Write a short note on the cold mold seal.

Or

Write a short note on sodium alginate.

Or

Write a short note on separating the medium.

Answer:

Separating media is defied as a coating applied to the surface and serves to prevent as second surface from adhering to the fist.

Types of Separating Media:

Various separating media used are:

Tin foil: It is widely used in the past but due to its time-consuming manipulation and laborious technique, it is replaced by tin foil substitutes.

Tin foil substitutes: A variety of alternating separating media was introduced instead of tin foil. So they are known as tin foil substitutes. Tin foil substitutes are:

- Cellulose lacquers

- Aqueous solution of sodium silicate

- Calcium oleate

- Soaps and starches

- Water soluble alginate solutions: Sodium and aluminum alginate solutions are commonly used.

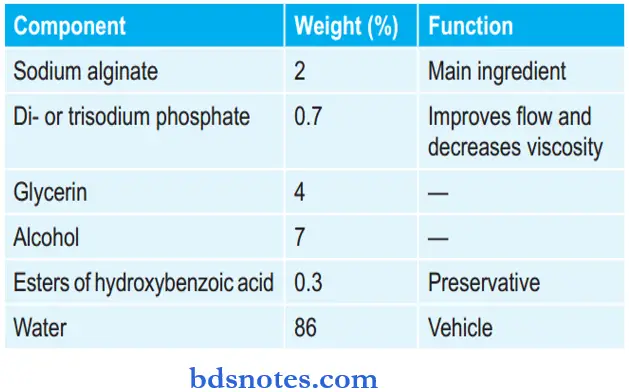

1. Cold Mold Seal:

- Sodium alginate solution also known as cold mold seal is the most commonly used separating media.

- Usually, two coats of sodium alginate solution are painted on gypsum cast as well as investment material which is left for drying, so it is called as paint-on separating media.

2. Mode of Reaction:

- When it is applied on gypsum surfaces sodium alginate reacts with calcium sulfate to form a thin insoluble film of calcium alginate.

- This coat of separating medium forms a barrier against acrylic flowing in micropores in gypsum which when polymerized is difficult to separate from the gypsum cast.

3. Method of Application:

- A small amount of separating medium is dispensed on a disposable container.

- A fine brush is used to spread the separating medium on the exposed surfaces of the warm, clean stone mold.

- Two coats of separating medium should be applied.

4. Precautions:

- The separator should not contact the exposed portions of acrylic resin teeth. This prevents the bonding of teeth with the denture base.

- Mold should be warm and not hot. Continuity of fim will break if mold is hot.

- Wax or oils remaining on the mold surface will interfere with the action of separating the medium.

- The coating must be thin and continuous without trapping air bubbles.

5. Purpose of Applying Separating Medium:

- To prevent water from the mold surface for entering in acrylic resin. This can affect the rate of polymerization and color. This can also lead to crazing.

- To prevent monomer from entering in mold material which causes plaster to adhere to acrylic resin and produce a rough surface.

- It helps in the easy retrieval of dentures from the mold.

Question 20. Write uses of acrylic resin And Light cure Acrylic resin.

Answer:

Uses of Acrylic Resin:

Heat-cure acrylic resin

- For fabricating complete and removable partial denture.

- For fabricating orthodontic appliances.

- For fabricating artifiial teeth.

- For fabricating obturators.

- For making temporary crown and bridges.

Light-cure Acrylic Resin:

- To fabricate special trays.

- To fabricate trial denture bases.

Question 21. Classify denture base materials. Describe in detail about manipulation of each type of resin.

Answer:

Manipulation of Each Type of Resin:

- Manipulation of Heat-cure Resin:

- Mix the correct proportion of polymer and monomer, i.e. polymer/monomer ratio is 3 to 3.5/1 by volume or 2.5:1 by weight.

- First, the liquid monomer is poured in a thick, clean glass jar and then powder is added slowly to it.

- After all powder is added the mix is stirred and vibrated thoroughly so that mechanically mixed pigments and dyes are dispensed evenly throughout the material.

- On completion of stirring, a light lid must be placed on the glass jar to prevent evaporation of the monomer.

- When polymer and monomer mix is allowed to stand in a closed container it undergoes physical changes due to the interaction of monomer to polymer.

- Manipulation of Chemically Activated Resin:

- The most commonly used techniques for the manipulation of self-cure resin is the sprinkle-on technique and hand-adapted dough method.

- Sprinkle-on technique: In this technique, both polymer and monomer are added to the cast which consists of separating medium.

- In this powder is added to the cast and monomer is added to it till the proper thickness is achieved.

- The liquid is added to the powder with the help of a dropper.

- Hand-adapted dough technique: In this technique, both the powder and liquid are proportionate and mixed in a porcelain jar.

- As the mix proceeds to dough stage, it is placed in between two glass slabs, now it is removed and is adapted to the cast manually in the desired shape.

- Manipulation of Light Activated Resin:

- Fabrication of denture base:

- As base material is in the plastic stage, it should be adapted on the master cast.

- Polymerize it to hard set in the light chamber without teeth to be used as a base plate.

- Completion of denture:

- Attach the teeth to base plate by additional material and the anatomy of the polished surface should be made accordingly.

- As sculpting is complete denture should be placed again in a light chamber for polymerization.

- As polymerization is over dentures should be finished and polished.

- Fabrication of denture base:

Question 22. Write a note on heat-cure denture base materials.

Or

Describe in detail the manipulation and properties of heat-cure acrylic denture base resin.

Answer:

Heat-cure Denture Base Materials:

They are most widely used resins for the construction of removable or complete dentures.

Properties Of Heat-cure Denture Base Materials:

- Taste and odor:

- Completely polymerized acrylic resin is tasteless and odorless.

- On the other hand, poorly made dentures with a high amount of porosity can absorb food and bacteria resulting in an unpleasant taste and odor.

- Esthetics:

- It is a clear transparent resin that can be pigmented (colored) easily to duplicate the oral tissue.

- It is also compatible with dyed synthetic filers thus esthetics is acceptable.

- Strength:

- These materials are typically low in strength.

- However, they have adequate compressive (75 MPa) and tensile strength (48 to 62 MPa) for complete or partial denture applications.

- Modulus of electricity: They have sufficient stiffness (2400 MPa) for use in complete and partial dentures.

- Dimensional stability:

- A well-processed acrylic resin denture has good dimensional stability.

- The processing shrinkage is balanced by the expansion due to water sorption.

- Solubility: Acrylic is virtually insoluble in water and oral fluids.

- Stability to heat: Polymethyl methacrylate is chemically stable to heat up to a point. It softens at 125°C.

- Color stability: Heat-cure acrylic resins have good color stability. The color stability of self-cure resin is slightly lower.

- Biocompatibility: Completely polymerized acrylic resins are biocompatible. True allergic reactions to acrylic resins are rarely seen in oral cavity.

- Adhesion: The adhesion of acrylic to plastic denture teeth is good chemical adhesion.

- Shelf life: Acrylic resins dispensed as powder and liquid have the best shelf-life.

- Radiopacity:

- There are instances of broken pieces of dentures being aspirated or swallowed.

- Radiopacity is a desirable property to enable easy location of fragments.

- Most denture base materials are radiolucent. Radiopacity is obtained by adding heavy metal salts such as bismuth or uranyl at a concentration of 10 to 15%.

Thermal properties:

- Stability to heat:

- Polymethyl methacrylate is chemically stable to heat up to a point. It softens at 125°C.

- However, above this temperature, i.e. between 125°C and 200°C it begins to depolymerize.

- At 450°C, 90% of the polymer will depolymerize to monomer.

Thermal conductivity:

- They are poor conductors of heat and electricity.

- This is undesirable because patients wearing acrylic complete dentures often complain that they cannot feel.

- The temperature of food or liquids they ingest, thus reducing the pleasure.

- Replacing the palatal portion with metal is one solution because the metal is a better conductor of heat.

- Coefficient of thermal expansion: These materials have a high coefficient of thermal expansion (CTE).

- The CTE for polymethyl methacrylate resin is 81 × 106/°C.

- The addition of filers reduces CTE.

- Heat distortion temperature: This is the measure of the ability of a plastic to resist dimensional change when loaded under heat.

- It is measured by observing the temperature at which a specimen under 1.8 MPa load defects 0.25 mm.

- Heat distortion temperature for PMMA — 71 to 91°C.

- Heat distortion temperature for vinyl resin — 54 to 77°C.

- Distortion is of concern during procedures like the repair or polishing of dentures. The temperature should be kept low to avoid distortion.

Polymerization Reaction: Polymerization of heat-activated resin is achieved by the application of heat and pressure.

The reaction is:

Powder + Liquid + Heat → Polymer + Heat

(Polymer) (Monomer) ( External) (Reaction)

Mode of Polymerization:

- Here the mode of polymerization is by application of external heat for activation of polymerization reaction which is provided by water bath or by microwave.

- Heat-activated resins are available in powder and liquid form.

Manipulation of Heat-cure Resin:

- Mix the correct proportion of polymer and monomer, i.e. polymer/monomer ratio is 3 to 3.5/1 by volume or 2.5/1 by weight.

- First, the liquid monomer is poured in a thick, clean glass jar and then the powder is added slowly to it.

- After all powder is added the mix is stirred and vibrated thoroughly so that mechanical mixed pigments and dyes are dispensed evenly throughout the material.

- On completion of stirring, a light lid must be placed on the glass jar to prevent evaporation of the monomer.

- When polymer and monomer mix is allowed to stand in a closed container it undergoes physical changes due to the interaction of monomer to polymer.

Advantages of Heat-cure Resin:

- Aesthetically it is good.

- It consists of the high glass transition temperature.

- It is easy to fabricate.

- Its surface finish is excellent.

Disadvantages of Heat-cure Resin:

- Its flexural strength is low.

- It has short fatigue life.

- It is radiolucent.

Uses of Heat-cure Resin:

- For fabricating complete and removable partial dentures.

- For fabricating orthodontic appliances.

- For fabricating artificial teeth.

- For fabricating obturators.

- For making temporary crowns and bridges.

Leave a Reply