Dental Investments And Refractory Materials

Question 1. What is casting shrinkage? How can we compensate for the same?

Or

Describe in brief with relation to gypsum bonded investments.

Or

How can you compensate for the casting shrinkage?

Answer:

Casting shrinkage: At the time of casting, the molten metal is forced in an investment mold to occupy the space occupied by the wax pattern before. As the molten metal cools at room temperature, it shrinks dimensionally this is known as casting shrinkage or solidification shrinkage.

Read And Learn More: Dental Materials Question And Answers

Shrinkage Occurs in Three Stages:

- Thermal contraction of the liquid material.

- Contraction of metal while changing from liquid to solid mass.

- Thermal contraction of solid metal as it reaches room temperature.

Compensation of Casting Shrinkage:

Shrinkage affects the fi of the restoration, therefore it must be controlled and compensated by the expansion of investment material. During heating, the investment expands thermally and this expansion compensates for the casting shrinkage.

Expansions of Investment by GypsumBonded Investment Materials:

Gypsum-bonded investment materials are used for the conventional casting of inlays, onlays, crowns, and fixed partial dentures made of gold alloys. Expansion of casting shrinkage by gypsum bonded investment is of 3 types:

- Normal settng expansion.

- Hygroscopic setting expansion.

- Thermal expansion.

1. Normal Setting Expansion:

- As water gets mixed with investment powder, water surrounds the calcium sulfate crystals and converts them into calciumα–dihydrate. Setting expansion enlarges the mold partially for casting shrinkage of gold alloys. The effectiveness of setting expansion depends on the thermal expansion of wax pattern.

- Expansion in the wax pattern is due to exothermic heat which is released from the investment while settling. As the soft is the wax and thin is the wax pattern, more is the expansion since the investment can move soft and thin wax more easily. ADA specification N o. 2 for type I investment permit maximum setting expansion in air of 0.5%. Modern investments show setting expansion of 0.4%.

2. Hygroscopic Setting Expansion

- Hygroscopic setting expansion is a continuation of normal setting expansion when it is allowed to set in the presence of water. Water has to be incorporated before the setting of investment takes place. This water replaces the water of hydration and prevents the confinement of crystal growth. So the crystals continue to grow outward in the presence of water which causes more expansion.

- Water here is provided to gypsum crystals from a wet liner which is placed over the inner surface of the casting ring or from the exposed surface of the investment which is immersed in water. Hygroscopic setting expansion is 5 to 6 times that of normal setting expansion. ADA specification no. 2 for type II investments requires a minimum of 1.2% and a maximum of 2.2% expansion.

3. Thermal Expansion: In the case of gypsum investment thermal expansion is achieved by placing the mold in the furnace at a temperature below 700°C (If the temperature is more than 700°C, the investment is breakdown and gases are released which contaminate the gold alloy).

- The thermal expansion of gypsum-bonded investment is directly related to the amount and type of silica.

- A considerable amount of quart or allotropic form of silica is necessary to counterbalance the contraction in the gypsum during heating.

- When investment is heated:

- The gypsum contracts between 200 to 400°C and a slight expansion takes place between 400°C to 700°C and a large contraction occurs after this.

- If a considerable amount of allotropes of silica are present in the investment this contraction can be eliminated and change in expansion. Because when heated, quart or crystabolite changes its crystalline form this occurs at a transition temperature.

- Quart when heated, inverts from a “low” form known as alpha quart to a “high” form known as beta quartz at a temperature of 370°C.

- Crystabolite similarly when heated inverts from ‘low’ or alpha crystalline to high or beta crystalline form at temperatures between 200°C and 270°C.

- The density changes (decreases) as alpha form changes to beta form with a resulting increase in volume and a rapid increase in linear expansion.

The permissible minimum and maximum thermal expansion for gypsum-bonded investments are 0 to 0.5% at 500°C and 1 to 1.6% at 700°C temperatures.

Question 2. Write a short note on investment material.

Or

Write a short note on dental investment material.

Or

Describe briefly investment material.

Answer:

An investment can be described as a ceramic material, which is suitable for forming a mold into which molten metal or alloy is cast. The procedure for forming the mold is described as “investing”.

Materials such as gypsum, phosphate, and silicate are used for investment as they can withstand higher temperatures of burnout and casting procedures. Investment material is available as a two-component system as powder and liquid, to be mixed before investing wax pattern.

Ideal Requirements for Dental Investment Material:

- The investment mold must expand to compensate for the alloy shrinkage that occurs during the cooling of the molten alloy.

- The powder should have a fine particle size to give a smooth surface to the casting.

- The manipulation should be easy. It should have a suitable setting time.

- The material should have a smooth consistency when mixed.

- The set material should be porous enough to permit air in the mold cavity to escape easily during casting.

- At higher temperatures, the investment must not decompose to give off gases that may corrode the surface of the alloy.

- It must have adequate strength at room temperature to permit handling and enough strength at higher temperatures to withstand the impact force of the molten metal.

- Casting temperature should not be critical.

- After casting, it should break away readily from the surface of the metal and should not react chemically with it.

- The material should be economical.

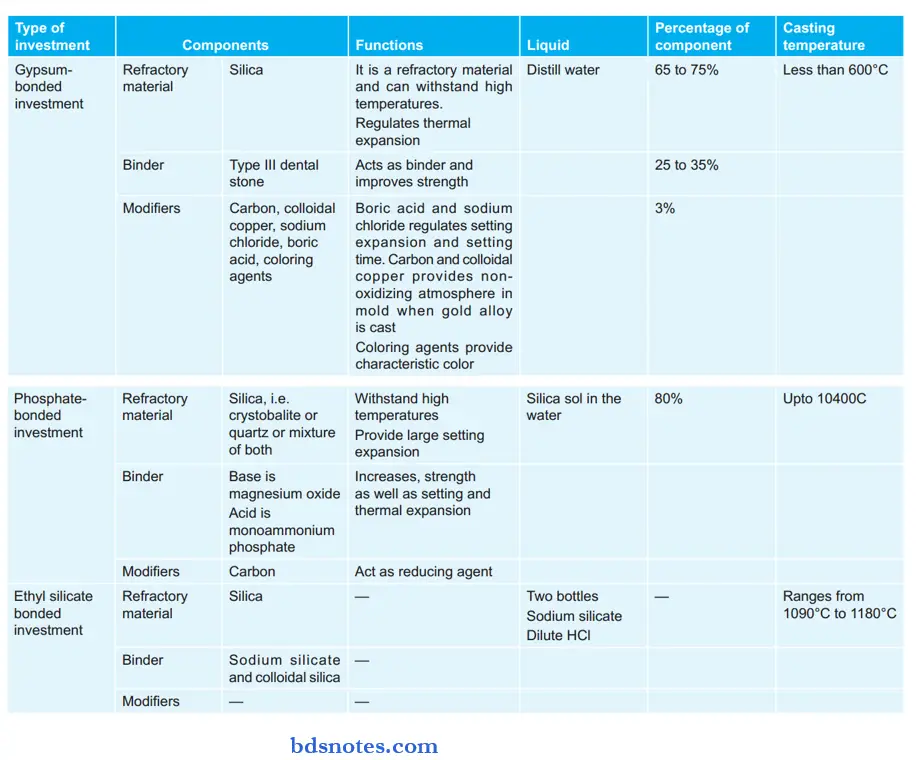

Composition of Investments Material:

All investment materials must contain a refractory and a binder.

Refractory: A material that will withstand high temperatures without decomposing or disintegrating, for example, Silica.

Silica exists in at least four allotropic forms:

- Quart

- Tridymite

- Crystabolite

- Fused quartz

They serve two functions:

- Act as a material that can withstand high temperatures.

- Regulates the thermal expansion.

Binder: A material that will set, and bind together the particles of refractory substances, for example, Gypsum, Phosphate, and Silicate.

Other chemicals: Other chemicals such as sodium chloride, boric acid, graphite, and copper are added in small quantities to modify the physical properties.

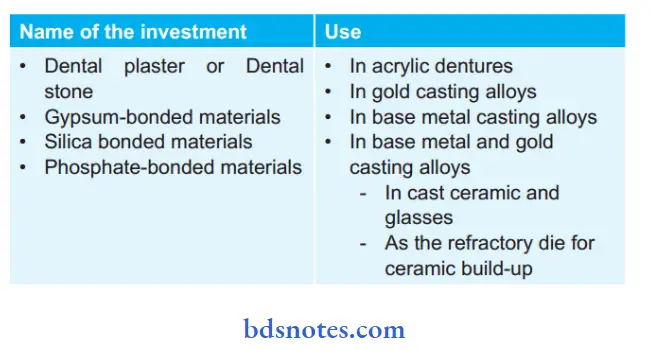

Types/Classification of Investment Materials:

1. Based on the Type of Binder Used: There are three types of investment materials. Based on the type of binder all contain silica as refractory material.

- Gypsum-bonded investment: A common type of binder used is alpha hemihydrate.

- Uses: For the casting of ‘inlays, bridges and removable partial denture framework using gold alloys and another low fusing alloy’.

- Phosphate-bonded investment: Ammonium diacid phosphate is used as a binder.

- Uses: For casting high-fusing alloys.

- For example High fusing noble metal alloys, metal-ceramic alloys, and base metal alloys like nickel-chromium and cobalt chromium.

- Silica-bonded investments: The silica is the binder. It is derived from ethyl silicate or aqueous dispersion of colloidal silica or sodium silicate.

- They are the alternatives to phosphate-bonded investments for high-temperature casting. They are primarily used in the casting of base metal alloy partial dentures.

2. Based on Application:

- Type 1: For the construction of inlays, crowns, and other fixed restorations.

- Type 2: For construction of complete or partial dentures or other removable partial appliances.

- Type 3: For construction of casts using brazing procedures.

- Type 4: For construction of refractory dies.

Applications of Investment Materials:

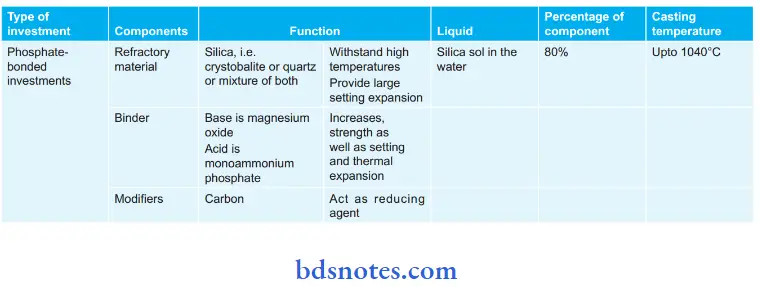

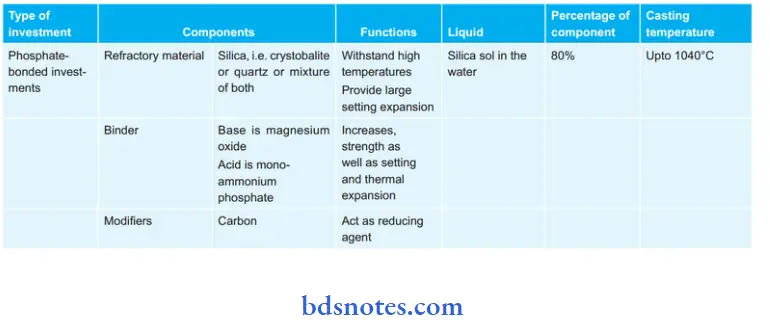

Question 3. Write a short note on phosphate-bonded investments.

Or

Write a short note on phosphate-bonded investment material.

Or

What is an investment? Describe phosphate-bonded investment in detail.

Answer:

An investment is defined as a ceramic material that is suitable for forming a mold into which molten metal or alloy is cast. Phosphate-bonded investments are the most commonly used investments in the casting of palladium-based alloys and base metal alloys.

Types of phosphate-bonded investment

Based on application they are classified into two types, i.e.

- Type I: For inlays, crowns, and other field restorations

- Type II: For partial dentures and other removable restorations

Composition of phosphate-bonded investment:

Setting Reaction of phosphate-bonded investment:

At room temperature, ammonium diacid phosphate reacts with magnesium oxide to give the investment green strength or room temperature strength.

NH4 + H2PO4 + MgO + 5H2O→ NH4Mg PO4 + H2O

Manipulation of phosphate-bonded investment:

- For manipulation, the power liquid ratio should be 16 to 23 mL/100 g. The powder is mixed with a measurable amount of liquid using a bowl and spatula. Hand mixing is done for 20 seconds and mechanical mixing is done for 90 seconds.

- Working time should be 8 to 9 minutes. Hand mixing or mechanical mixing under a vacuum can be done. The mixed material is vibrated into the casting ring or agar mold (RPD frameworks). The bench set for material should be for 30 to 45 minutes depending on the particular investment.

Properties of phosphate-bonded investment:

- Expansion: Expansion of mold compensates for casting shrinkage. Phosphate investments have their expansion from three sources:

- Wax pattern expansion: Heat during setting allows for proper expansion of the wax pattern.

- Setting expansion: It is 0.7 to 1%.

- Thermal expansion: It ranges from 1 to 1.5%.

- Strength: Its wet strength is from 4 to 10 MPa. According to the studies, there is no correlation between the wet and dry strength of phosphate-bonded investments.

- Thermal Reaction: Phosphate investments undergo thermochemical reactions when they are heated to high temperatures.

- Flow: When the phosphate investment is mixed it appears to have low flow. This material flows readily and covers the pattern when it is poured in mold under vibration. So use of a vibrator is recommended. Reducing agents should be used on wax patterns to improve wetting.

- Surface Smoothness: Early phosphate investments produce rough castings when compared to gypsum-based investments. Current phosphate investments have improved surface smoothness comparable to gypsum-bonded investments.

Question 4. Write a short note on binding agents in investment materials.

Answer:

A material that will set and bind together the particles of a refractory substance known as a “binder”.

In gypsum-bonded investment: Dental stone (alpha hemihydrate) acts as a binder for investment used in casting gold-containing alloys.

- It permits the pouring of the mix into the mold.

- It binds and holds the silica particles together.

- It imparts strength to the mold.

In phosphate-bonded investment: The binder consists of magnesium oxides (basic) and a phosphate that is acid in nature. Originally phosphoric acid was used, but monoammonium phosphate has replaced it because it can be incorporated into the investment powder.

In silica-bonded investment: The silicate is a binder.

- It is derived from ethyl silicate or aqueous dispersion of colloidal silica or sodium silicate.

- Ethyl silicate has the disadvantage of containing inflammable components which are required for manufacture.

- Sodium silicate and colloidal silica are more commonly used as binders.

Soldering investment:

Binder:

- Calcium sulfate

- Hemihydrate.

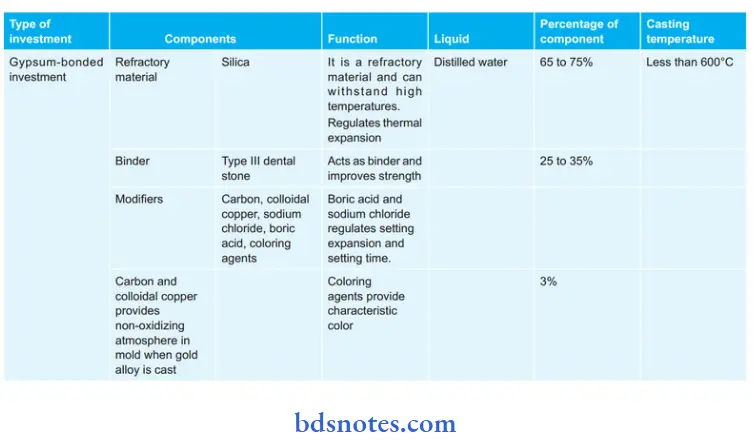

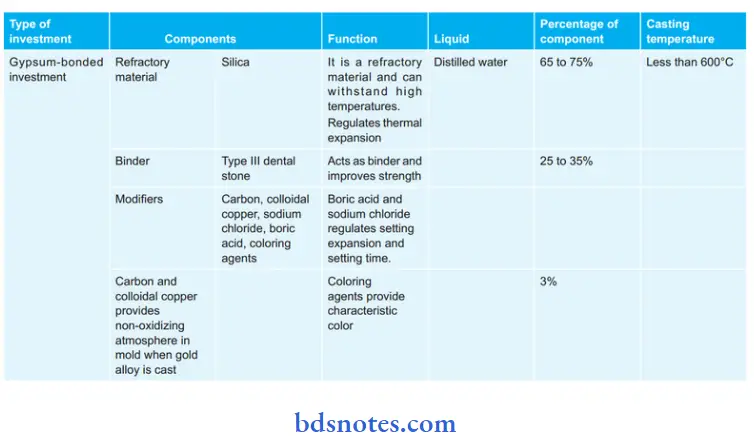

Question 5. Write a note on gypsum-bonded investment materials.

Or

Write a short note on gypsum-bonded investment.

Answer:

Gypsum-bonded investments are used for casting gold alloys. They can withstand temperatures up to 700°C.

Classification of gypsum-bonded investment:

As per ADA specification No. 2

- Type I- For casting inlays or crowns

- Type II- For casting partial and complete denture bases.

Composition of gypsum-bonded investment:

The function of Each Constituent:

- Alpha hemihydrate:

- It binds and holds the silica particles together.

- Permits pouring of the mix into the mold.

- It imparts strength to the mold.

- Contributes to mold expansion (by setting expansion).

- Silica: Quart or cristobalite

- Acts as a refractory during heating.

- Regulates thermal expansion.

- Increases setting expansion of stone.

- Silica in the investment eliminates the contraction of gypsum and changes it to an expansion during heating.

- Modifiers:

- Coloring matter

- Reducing agents: They reduce any oxides formed on the metal by providing a non-oxidizing atmosphere in the mold when the mold alloy enters, for example, Carbon

or copper powder. - Modifying chemicals: They regulate setting expansion and setting time and also prevent shrinkage of gypsum when heated above 300°C, for example, Boric acid and sodium chloride.

Manipulation of gypsum-bonded investment: The measured quantity of powder and water is mixed manually using a flexible rubber bowl and spatula or in a vacuum investment mixing machine.

Setting Reaction of gypsum-bonded investment: When water is mixed the hemihydrates react to form dihydrate which sets to form a solid mass that binds the silica particles together.

Uses of gypsum-bonded investment: Casting of inlays, bridges, removable partial denture framework using gold alloys and another low-fusing alloy.

Question 6. Write in detail about investing and burnout procedure for gold fied partial denture.

Answer:

Investing Procedure for Gold Fixed Partial Denture:

- We use gypsum-bonded investing material type III for gold fixed partial dentures.

- Apply a wetting agent on the wax pattern.

- Seat casting ring into crucible former taking care that it is located near center of the ring.

- Mix investment and vibrate.

- The same investment is applied to the wax pattern with a brush to reduce trapping air bubbles.

- The ring is reseated on the crucible former placed on the vibrator and gradually filed with the remaining investment mix. Allow it to set for 1 hour.

Burnout Procedure for Gold Fixed Partial Denture:

- Burnout is started when the mold is set.

- Store in a humidor if burnout is to be delayed. Heating should be gradual.

- Rapid heating produces steam which causes the walls of the mould cavity to fake.

- The ring is placed in a burnout furnace and heated gradually to 400°C for 20 minutes maintained it for 30 minutes.

- In the next 30 minutes, raise the temperature to 700°C and again maintain for 30 minutes.

- Casting should be completed as soon as the ring is ready.

Question 7. Define and classify dental casting investment materials. Write about the composition and setting mechanism of phosphate-bonded investment material.

Or

Classifyinvestmentmaterials.

Answer:

An investment is described as a ceramic material that is suitable for forming a mold into which molten metal or alloy is cast. The procedure for forming the mold is known as investing.

Classification of Dental Casting Investment Materials:

- Based on the Type of Binder Used: There are three types of dental casting investment materials based on the binder used.

- Gypsum-bonded investments: They are used for casting gold alloys. They can withstand temperatures to 700°C.

- Phosphate-bonded investments: They are used for metal ceramic and cobalt-chromium alloys. They can withstand higher temperatures.

- Ethyl silica bonded investments: It is an alternative to phosphate-bonded investments for high-temperature casting. They are used in the casting of base metal alloy partial dentures.

2. Based on application:

- Type 1: For the construction of inlays, crowns, and other fields

restorations. - Type 2: For the construction of complete or partial dentures or other

removable partial appliance. - Type 3: For the construction of casts using brazing procedures.

- Type 4: For the construction of refractory dies

Composition of Phosphate – Bonded Investment material:

Setting mechanism of phosphate-bonded investment material:

Ammonium phosphate and magnesium oxide react with water to form hydrated magnesium ammonium phosphate and water.

The chemical reaction is:

NH4H2PO4 + MgO + 5H2O → NH4MgPO4.6H2O + MgO + NH4H2PO4 + H2O

(Room temperature)

Excess of magnesia and water are present. Some of the magnesia is never fully reacted. Settling reaction continues to occur as there is an increase in temperature at the time of burnout. Water produced during this reaction decreases the viscosity of the mix as speculation continues.

The formation of magnesium ammonium phosphate plays a role as the binding medium in which filer particles get embedded in the matrix. This reaction is the hydration reaction which is followed by a crystallization reaction. The set matrix consists of multimolecular NH4H2PO4 which aggregates around an excess of magnesium oxide and filers.

Setting Reaction at Higher Temperatures:

- Now as the temperature of the investment increases (burnout temperature) setting reaction continues. A sequence of both chemical and thermal reactions with various phase changes occurs at the time of settling and burnout, providing room-temperature strength, and high-temperature strength which enables the investment to withstand high casting temperatures of metal alloy.

- At a temperature of about 300°C, ammonia and water are liberated leading to the degradation of small amounts of magnesium ammonium phosphate which results in shrinkage of the investment, now this is compensated by the outward thrust of the expanding silica forms.

- At higher temperatures, phosphate reacts with silica and forms complex silicophosphates. The strength of the investment increases by the formation of silicophosphates on heating.

Question 8. Write a short note on the composition of gypsum-bonded investments.

Answer:

Composition of gypsum-bonded investments.

- Silica—60–65%: Act as a refractory material. During heating this material will withstand high temperatures without decomposing or disintegration. It also regulates thermal expansion.

- Alpha hemihydrate (dental stone) 30–35%: It acts as a binder and it binds and holds the silica particles together. It imparts strength to the mold.

- Chemical modifirs-5%:

- Coloring material.

- Reducing agents: They reduce any oxides formed on the surface of the metal by providing a non-oxidizing atmosphere in the mold, for example, Carbon or copper powder.

- Modifying chemicals: They regulate setting expansion and setting time, e.g. boric acid and sodium chloride.

Question 9. What is a reservoir?

Answer:

A reservoir is that part of a spread network that solidifies last and hence can act as a source of supply of molten material to the mold cavity. It helps to compensate for solidification shrinkage and prevent localized shrinkage porosity.

Question 10. What is a ring liner?

Answer:

A material that allows uniform expansion of the investment which compensates for casting shrinkage is called as ring liner.

Question 11. Write notes on casting shrinkage.

Or

Write a short note on casting shrinkage.

Or

Answer:

Casting Shrinkage:

- At the time of casting, the molten metal is forced into an investment mold to occupy the space occupied by the wax pattern before. As the molten metal cools at room temperature, it shrinks dimensionally this is known as casting shrinkage

- The casting shrinkage of gold alloy is about 1.25–1.65% and for cobalt-chromium alloys, it is about 2.25%.

- High shrinkage is due to high fusion temperature.

- Silica or phosphate-bonded investments are used to compensate shrinkage for cobalt-chromium alloys.

- Casting shrinkage can be compensated by the expansion of mold investments.

- The setting, hygroscopic, and thermal expansion can be controlled by varying P/L ratios of investments.

- Increasing the burn-out temperature and water bath temperature increases the expansion and vice versa.

- In the controlled water-added technique, water is added during the setting of investment to compensate for the casting shrinkage.

Shrinkage Occurs in three Stages:

- Thermal contraction of liquid metal between temperature to which it is heated and the liquidus temperature.

- The contraction of the metal in heat its changes from a liquid to a solid state.

- The thermal contraction of the solid metal occurs on further cooling to room temperature.

For Phosphate-bonded Investments:

- The expansion of mold is desirable to compensate for casting shrinkage. The expansion of phosphate-bonded investments depends on the thermal expansion of the material. At higher temperatures, melting alloys have high contraction at the time of solidification which necessitates greater expansion of investment. This is done by thermal expansion of investment and inversion of silica.

- Replacement of liquid components from water to colloidal silica increases hygroscopic expansion. So the expansion of investment varies as per the ratio of colloidal silica to water. As the ratio of colloidal silica to water increases, the expansion increases.

- So when the ratio of colloidal silica to water is 1:3 expansion of phosphate investment material is 1.3% to 1.5%; the ratio of 1:1 leads to an expansion of 1.5 to 1.7% and the ratio of 3:1 leads to an expansion of 1.7 to 1.9%.

Expansion of phosphate investment occurs from three sources, i.e.

- Wax pattern expansion: Heat during setting allows significant expression of wax pattern.

- Setting expansion: It is 0.7 to 1%.

- Thermal expansion: It is 1 to 1.5%.

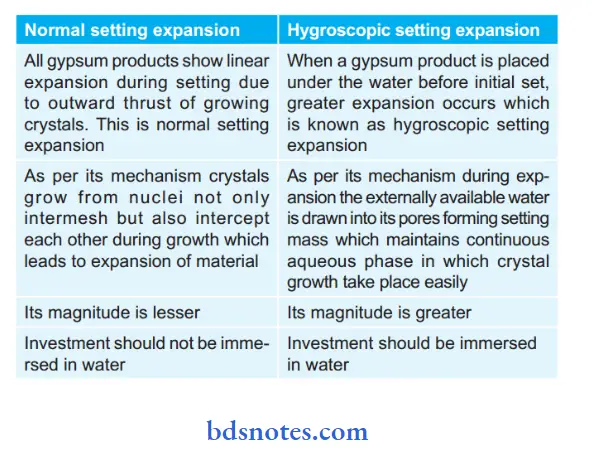

Question 12. Write on differences between the normal and hygroscopic setting expansion of gypsum products.

Answer:

Following are the differences between normal and hygroscopic setting expansion:

Question 13. Describe how casting shrinkage occurs.

Answer:

All castings will shrink as the metal transitions from a liquid state to a solid state. As a casting cools there are three phases of shrinkage, liquid shrinkage, solidification shrinkage, and solid shrinkage.

- Liquid shrinkage is where the melt cools and as it is cooling the melt is changing volume in its liquid form. Solidification shrinkage is an effect of the phase change from liquid to solid.

- This is just the same as water changing phase from liquid to ice. Solid shrinkage is a stage of shrinkage where the temperature of the solidified casting is decreasing causing the casting volume to decrease also.

- Liquid shrinkage and solidification shrinkage are the primary cause of shrinkage defects in castings.

- The design of the part will determine the likelihood that a shrinkage defect will occur. Gating and risering are employed in such a way as to reduce the amount of shrinkage or move it into a non-critical area of the casting.

- The third phase, solid shrinkage, occurs after the metal has solidified. This shrinkage is accounted for in the pattern sizing.

Question 14. Write in detail about different types of expansions to compensate for the casting shrinkage.

Answer:

Following are the different types of expansions to compensate for the casting shrinkage:

Normal Setting Expansion:

- As the water gets mixed with investment powder, water surrounds the calcium sulfate crystals and converts them into calcium α-dihydrate. Setting expansion enlarges the mold partially for casting shrinkage of gold alloys.

- The effectiveness of setting expansion depends on the thermal expansion of the wax pattern. Expansion in the wax pattern is due to exothermic heat which is released from the investment while setting.

- As the soft is the wax and thin is the wax pattern, more is the expansion since the investment can move soft and thin wax more easily. ADA specification no. 2 for type I investment permits a maximum setting expansion in air of 0.5%. Modern investments show a setting expansion of 0.4%.

Hygroscopic Setting Expansion or Low Heat Technique:

- Hygroscopic setting expansion is a continuation of normal setting expansion when it is allowed to set in the presence of water. Water has to be incorporated before the setting of the investment takes place. This water replaces the water of hydration and prevents the confinement of crystal growth.

- So the crystals continue to grow outward in the presence of water which causes more expansion. The water here is provided to gypsum crystals from wet liner which is placed over the inner surface of the casting ring or from the exposed surface of the investment which is immersed in water.

- Hygroscopic setting expansion is 5 to 6 times that of normal setting expansion. ADA specification no. 2 for type II investments requires a minimum of 1.2% and a maximum of 2.2% expansion.

Thermal Expansion or High Heat Technique:

For Gypsum-bonded Investment

- In the case of gypsum investment thermal expansion is achieved by placing the mold in the furnace at a temp below 700°C (If the temperature is more than 700°C, the investment is breakdown, and gases are released which contaminate the gold alloy).

- The thermal expansion of gypsum-bonded investment is directly related to the amount and type of silica.

- A considerable amount of quart or allotropic form of silica is necessary to counterbalance the contraction in the gypsum during heating.

- When investment is heated: The gypsum contracts between 200 to 400°C and a slight expansion takes place between 400°C to 700°C and a large contraction occurs after this.

- If a considerable amount of allotropes of silica are present in the investment this contraction can be eliminated and change in expansion. Because when heated, quart or crystabolite changes its crystalline form this occurs at a transition temperature.

- Quart when heated, inverts from a “low” form known as alpha quart to a “high” form known as beta quartz at a temperature of 370°C.

- Crystabolite similarly when heated inverts from ‘low’ or alpha-crystalline to high or beta-crystalline form at temperatures between 200°C and 270°C.

- The density changes (decreases) as alpha form changes to beta form with a resulting increase in volume and a rapid increase in linear expansion.

- The permissible minimum and maximum thermal expansion for gypsum-bonded investments are 0 to 0.5% at 500°C and 1 to 1.6% at 700°C temperatures.

For Phosphate-bonded Investment:

- The expansion of phosphate-bonded investments depends on the thermal expansion of the material. At higher temperatures, melting alloys have high contraction at the time of solidification which necessitates greater expansion of investment.

- This is done by thermal expansion of investment and inversion of silica. Replacement of liquid components from water to colloidal silica increases hygroscopic expansion.

- So the expansion of investment varies as per the ratio of colloidal silica to water. As the ratio of colloidal silica to water increases, the expansion increases. So when the ratio of colloidal silica to water is 1:3 expansion of phosphate investment material is 1.3% to 1.5%; the ratio of 1:1 leads to an expansion of 1.5 to 1.7% and a ratio of 3:1 leads to an expansion of 1.7 to 1.9%

Question 15. Describe the composition and properties of gypsum-bonded investment material.

Answer:

Composition of Gypsum-bonded Investment Material:

Properties of Gypsum-bonded Investment Materials:

- Thermal Behavior of Gypsum: When gypsum is heated to a high temperature, it shrinks and fractures. At 700°C, it shows slight expansion and then a great amount of contraction. The shrinkage is due to the decomposition and the release of sulfur dioxide. It contaminates the casting with the sulfides of silver and copper. So the gypsum-bonded investments should not be heated above 700°C.

- Thermal Behavior of Silica: When heated, quart or cristobalite changes its crystalline form. This occurs at a transition temperature, characteristic of the particular form of silica.

- Quart when heated, inverts from a ’low’ form known as alpha-quart to a high form called as beta-quart at a temperature of 375°C.

- Cristobalite similarly when heated, inverts from low or alpha-cristobalite to high or beta-cristobalite at a temperature between 200°C and 270°C.

The beta forms are stable only above the transition temperature. It changes back to the low or alpha form that occurs upon cooling in each case. The density changes (decreases) as alpha-form changes to beta-form with a resulting increase in volume and a rapid increase in linear expansion.

Expansion of Gypsum-bonded Investment Material:

- Normal Setting Expansion: As water get mixed with investment powder, water surrounds the calcium sulfate crystals and converts them into calcium α-dihydrate. Setting expansion enlarges the mold partially for casting shrinkage of gold alloys.

- The effectiveness of setting expansion depends on the thermal expansion of the wax pattern.

Expansion in the wax pattern is due to exothermic heat which is released from the investment while setting. As the soft is the wax and thin is the wax pattern, more is the expansion since the investment can move soft and thin wax more easily. - ADA specifications No. 2 for type I investment permit maximum setting expansion in the air of 0.5%. Modern investments show a setting expansion of 0.4%.

- The effectiveness of setting expansion depends on the thermal expansion of the wax pattern.

- Hygroscopic Setting Expansion: Hygroscopic setting expansion is a continuation of normal setting expansion when it is allowed to set in the presence of water. Water has to be incorporated before the setting of the investment takes place.

- This water replaces the water of hydration and prevents the confinement of crystal growth.

So the crystals continue to grow outward in the presence of water which causes more expansion. - Water here is provided to gypsum crystals from a wet liner which is placed over the inner surface of the casting ring or from the exposed surface of the investment which is immersed in water.

- Hygroscopic setting expansion is 5 to 6 times that of normal setting expansion. ADA specification N o. 2 for type II investments requires a minimum of 1.2% and a maximum of 2.2% expansion.

- This water replaces the water of hydration and prevents the confinement of crystal growth.

- Thermal Expansion:

- In the case of gypsum investment, thermal expansion is achieved by placing the mold in the furnace at a temperature below 700°C (If the temperature is more than 700°C, the investment is a breakdown, and gases are released which contaminate the gold alloy).

- The thermal expansion of gypsum-bonded investment is directly related to the amount and type of silica.

- A considerable amount of quart or allotropic form of silica is necessary to counterbalance the contraction in the gypsum during heating.

- When investment is heated: The gypsum contracts between 200 to 400°C and a slight expansion takes place between 400°C to 700°C and a large contraction occurs after this.

- If a considerable amount of allotropes of silica are present in the investment this contraction can be eliminated and change in expansion.

- Because when heated, quart or cristobalite changes its crystalline form this occurs at a transition temperature

- Quart when heated, inverts from a “low” form known as alpha quart to a “high” form known as beta-quart at a temperature of 370°C.

- Crystabolite similarly when heated inverts from ‘low’ or alpha crystalline to high or beta-crystalline form at temperatures between 200°C and 270°C.

- The density changes (decreases) as alpha-form changes to beta-form with a resulting increase in volume and a rapid increase in linear expansion.

- The permissible minimum and maximum thermal expansion for gypsum-bonded investments are 0 to 0.5% at 500°C and 1 to 1.6% at 700°C temperatures.’

Strength: According to ISO 15912:2006, the compressive strength for investments should not be less than 2 MPa when tested 2 hours after setting.

The porosity: More the gypsum crystals present in the set investment, the less is its porosity. Less is the hemihydrate content and the greater the amount of gauging water, the more is its porosity. A mixture of coarse and fine particles exhibits less porosity than an investment composed of uniform particle size.

Fineness: A fine particle size is preferable to a coarse one. The faster the investment, the smaller will be the surface irregularities on the casting.

Storage: Investments should be stored in airtight and moisture-proof containers. Purchase in small quantities.

Question 16. Define investment materials. Write about the ideal requirements of investment materials.

Answer:

An investment material is defined as a ceramic material that is suitable for forming a mold into which a metal or alloy is cast.

Ideal Requirements of an Investment Material:

- The investment mold must expand to compensate for the alloy shrinkage that occurs during the cooling of the molten alloy.

- The powder should have a fine particle size to give a smooth surface to the casting.

- The manipulation should be easy. It should have a suitable setting time.

- The material should have a smooth consistency when mixed.

- The set material should be porous enough to permit air in the mold cavity to escape easily during casting.

- At higher temperatures, the investment must not decompose to give of gases that may corrode the surface of the alloy.

- It must have adequate strength at room temperature to permit handling, and enough strength at higher temperatures to withstand the impact force of the molten metal.

- Casting temperature should not be critical.

- After casting, it should break readily from the surface of the metal and should not react chemically with it.

- The material should be economical

Leave a Reply