Dental Casting And Metal Fabrication Procedures

Question 1. Write a short note on back pressure porosities in casting.

Or

Write a short note on back pressure porosity.

Or

Answer briefly back pressure porosity as a casting defect.

Answer:

It is also known as entrapped air porosity. Back pressure porosity occurs on the inner surface of the casting as a large concave depression.

Read And Learn More: Dental Materials Question And Answers

Cause of Porosity:

Due to the inability of air to escape through the investment and accumulation of an air pocket which exerts pressure back toward the sprue and button.

Mechanism of Porosity:

- Air is trapped in the mold and is unable to escape. Sprue pattern length should be adjusted so that there is not more than ¼” thickness of the investment between the bottom of the casting ring and the wax pattern.

- When molten metal enters the mold, the air inside is pushed out through the porous investment at the bottom. If the bulk of investment is too great, the escape of air becomes difficult causing increased pressure in a mold. Gold will then solidify before the mold is completely filed resulting in porous casting with rounded short margins.

Casting Failures & Defects in Dentistry

The appearance of Porosity:

This porosity is found as a pocket on the surface of the crown or MOD casting.

Avoided by:

- Using adequate casting force.

- Use of investment of adequate porosity

- Place a pattern not more than 6 to 8 mm away from the end of the ring.

- By providing vents in large castings.

Question 2. Enumerate defects in casting. Discuss in detail casting porosities.

Or

Write a short note on porosities in casting defects.

Or

Write a short note on porosities in dental castings.

Or

Write a short note on porosity in dental castings.

Or

Classify various types of casting defects. Describe in detail common types of casting defects in dental castings.

Answer:

If proper procedure is not followed, the casting may have some defects, and the casting in such a case may not fit or may have poor esthetic and mechanical properties.

The casting of Defects:

- Distortion

- Surface roughness

- Porosity is one of the most common types of defect in dental casting

- Incomplete casting

- Contaminated casting.

The porosity of Defects:

Porosity may be external or internal. External porosity can cause “discoloration” of the casting. Internal porosity weakens the restoration.

Casting Failures & Defects in Dentistry

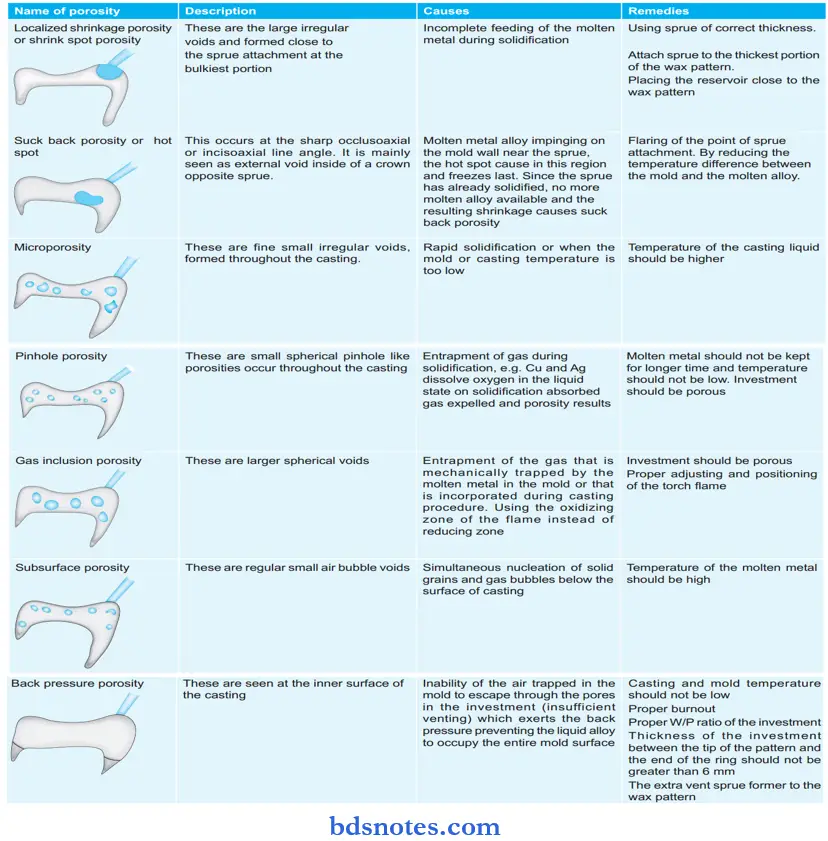

Porosities are Classified as:

- Those caused by solidification shrinkage:

- Localized shrinkage porosity

- Suck back porosity

- Microporosity.

- Those caused by gas:

- Pinhole porosity

- Gas inclusion (spherical in shape)

- Subsurface porosity.

- Those caused by air trapped in the mold:

- Back pressure porosityimg

Question 3. Write a short note on surface irregularities on casting.

Answer:

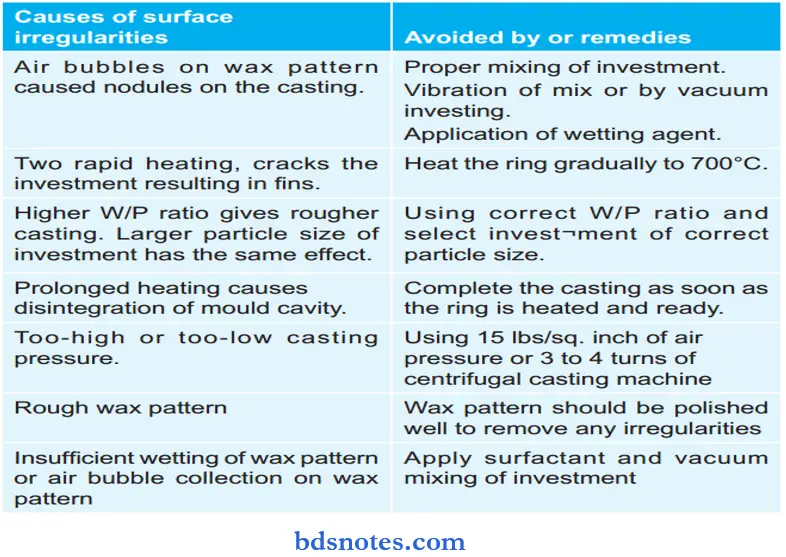

Surface irregularities are isolated imperfections such as nodules and scratches which are not characteristic of the entire surface area

Question 4. Write a short note on pickling.

Answer:

After removing the investment the surface of the casting appears dark with oxides and tarnish. Such surface film can be removed by a process known as “pickling” which consists of heating the discolored casting in an acid.

- One of the best pickling solutions for gypsum-bonded investment is a 50% hydrochloric acid solution.

- Hydrochloric acid aids in the removal of any oxide coating as well as any residual investment.

- The disadvantage of HCl is that the fumes from the acid are likely to corrode laboratory metal furnishing.

- In addition, these fumes are a health hazard.

- Ultrasonic devices are useful for cleaning the casting, as are commercial pickling solutions made of acid salt.

- Abrasive blasting devices are also useful for cleaning the surface of the casting.

- The best method for pickling is to place the casting in a test tube or dish and pour the acid over it.

- It may be necessary to heat the acid, but boiling should be avoided because of the considerable amount of acid fumes involved.

- After pickling the acid is poured off and the casting is removed.

Casting Failures & Defects in Dentistry

Question 5. Write a short note on sprue and sprue former.

Answer:

Sprue can be defined as a channel created in the investment through which molten metal enters the mold space which is created due to the burnout of wax pattern. Sprue formers are the materials that form sprues. Sprue former can be made up of wax, metal, plastic/resin.

Functions of Sprue:

- It forms a mount for the wax pattern.

- To create a channel for the elimination of wax during burnout.

- Forms a channel for entry of molten alloy during casting.

- Provides a reservoir of molten metal that compensates for alloy shrinkage during solidification.

Dental Casting Alloy

Dimensions of Sprue Former:

- Diameter: This depends on the thickness of the wax pattern. The diameter should be equal to the thickest portion of the wax pattern.

- Location: Sprue should be attached to the widest part of the wax pattern to allow proper flow of molten metal. Sprue should also be placed towards the center to wax pattern to allow molten metal to be directed at all parts of the mold.

- Direction: Sprue former should be attached at 450 to the thickest part of the wax pattern. The direction of the sprue should also remain away from a thin portion of the wax pattern because molten metal can fracture investment material in this area leading to failure of casting.

- Attachment: The dimension of connection between the sprue former and wax pattern depends on the density of the metal that has to be cast. Flaring of sprue should be done as it is attached to a wax pattern to allow the entry of molten metal freely into the mold. As the sprue gets attached to the widest part of the pattern, the molten metal will flow from a thick section of mold to thin areas.

- Length: The length of the sprue solely depends on the length of the casting ring. The length of the sprue former should be adjusted so that the upper end of the wax pattern is within 6 mm of the open end of the casting ring for gypsum-bonded investments and 3 to 4 mm for phosphate-bonded investments. This gives a good strength.

Question 6. Describe casting defects and their remedies in detail.

Or

Classify casting defects and various methods to compensate for defects.

Or

Discuss casting defects in detail.

Or

Classify casting defect. Write in detail about casting defects.

Or

Describe and classify casting defects. Write in detail about casting defects.

Or

Write in detail about casting defects in metals.

Or

Write a short note on casting defects.

Or

Write briefly on casting defects.

Or

Write a short answer on casting defects.

Answer:

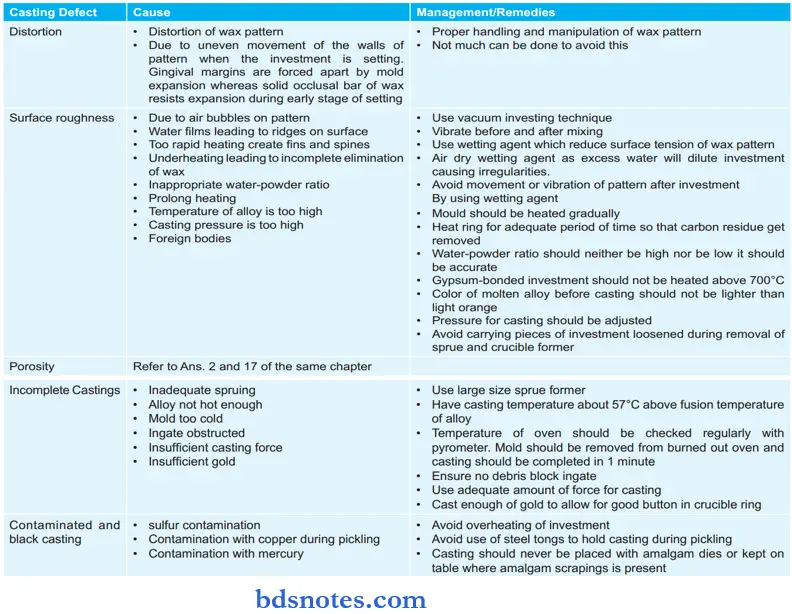

If proper procedure is not followed the casting has some defects.

Classification of Casting Defects:

- Distortion

- Surface roughness

- Porosity

- Incomplete casting

- Contaminated and black casting.

Question 7. Describe briefly suck back porosity.

Answer:

It is also known as hot spot porosity. This occurs at the sharp occlusoaxial or incisoaxial line angle. It is mainly seen as an external void inside of a crown opposite sprue.

Cause Of Suck Back Porosity:

Molten metal alloy impinging on the mold wall near the sprue, the hot spot caused in this region and freezes last. Since the sprue has already solidified, no more molten alloy is available and the resulting shrinkage causes suck-back porosity.

Remedies Cause Of Suck Back Porosity:

- Flaring of the point of sprue attachment.

- By reducing the temperature difference between the mold and the molten alloy.

Types Of Casting Defects

Question 8. Write a short note on casting ring liners.

Answer:

A ring liner is placed inside of the casting ring. Earlier asbestos liners were used. Its use has been discontinued due to the health hazard of breathing its dust.

Functions of Ring Liner:

- Allows for mold expansion. (Acts as a cushion)

- When the ring is transferred from the furnace to the casting machine, it reduces heat loss as it is a thermal insulator.

- It permits easy removal of the investment after casting.

A casting ring liner is placed under the casting ring. The casting ring liner should be 3 mm short at one end to allow proper contact between the investment and casting ring once the liner is burnt out.

Types of Ring Liners:

- Asbestos ring liner: Discontinued using due to health hazard

- Non-asbestos ring liner:

- Fibrous ceramic aluminous silicate

- Cellulose

- Ceramic–cellulose combination.

Functions of Ring Liners:

- It leads to mold expansion.

- It acts as a thermal insulator when the ring is transferred from the furnace to the casting machine.

- It causes easy removal of investment after casting.

Question 9. Classify investment material and casting failure

Answer:

Classification of Investment Materials:

Types Of Casting Defects

1. Based on the Type of Binder Used:

There are three types of investment materials. Based on the type of binder all contain silica as refractory material.

Gypsum-bonded investment: A common type of binder used is alpha hemihydrate.

- Use: For the casting of inlays, bridges, and removable partial denture frameworks using gold alloys and another low-fusing alloy.

Phosphate-bonded investment: Ammonium diacid phosphate is used as a binder.

- Use: For casting high-fusing alloys. For example, fusing noble metal alloys, metal-ceramic alloys, and base metal alloys like nickel-chromium and cobalt chromium

Silica-bonded investments: The silica is the binder. It is derived from ethyl silicate or aqueous dispersion of colloidal silica or sodium silicate.

- They are the alternatives to phosphate-bonded investments for high-temperature casting.

- They are primarily used in the casting of base metal alloy partial dentures.

2. Based on application:

- Type 1: For the construction of inlays, crowns, and other field restorations.

- Type 2: For the construction of complete or partial dentures or other removable partial appliances.

- Type 3: For the construction of casts using brazing procedures.

- Type 4: For the construction of refractory dies.

Classification of Casting Failures:

- Distortion

- Surface roughness

- Porosity

- Incomplete casting

- Contaminated and black casting.

Question 10. Write a short note on casting the crucible.

Answer:

- The crucible is heat resistant container in which alloy is melted before casting.

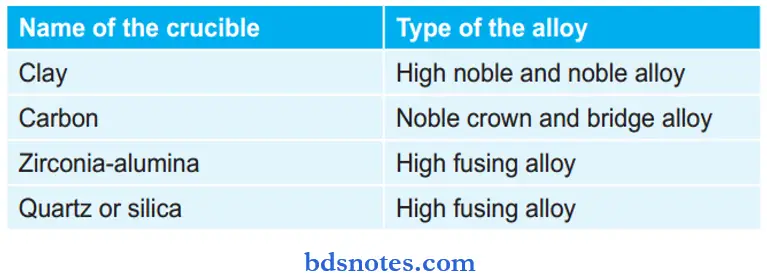

- There are four types of casting crucibles, i.e. Clay, carbon, quart, and zirconia-alumina.

- Clay crucibles are used for high noble and noble type alloys while carbon crucibles are used for high noble crown and bridge alloys and for high fusing, gold-based metal ceramic alloys.

- Alumina, quart, or silica crucibles are recommended for high-fusing alloys that have high melting temperatures and are sensitive to carbon contamination.

- So carbon crucibles are not used with high palladium, silver palladium, nickel-chromium, and cobalt-chromium alloys.

Various crucibles and alloys are used in them

Question 11. Write briefly about the casting machine.

Answer:

The casting machine accelerates molten metal in the mold by centrifugal force under the air pressure of a vacuum or by a combination of both. All the casting machines work on the principle of centrifugal force which drives molten metal in the mold.

Types of Casting Machines

Centrifugal Casting Machine:

- This is carried out by melting alloy in a separate crucible and molten metal is forced in the mold by centrifugal force.

- Centrifugal force is created by spring-wound which depends on the amount of molten metal which is to be cast and desired speed of rotation.’

- Attach the crucible to the free arm of the casting machine. The spring of the casting machine is wound and locked.

- As the heating casting ring is placed and the alloy is melted to casting temperature, spring is released which leads to the initiation of rotational motion.

- The free arm of the crucible accelerates the initial rotational speed of the casting machine.

Electrical Resistance Heated Centrifugal Casting Machine:

- In this machine, the alloy is placed in a graphite or ceramic crucible and is heated with the help of a resistance-based heating unit.

- As crucible in this machine is located flush with the casting ring. This leads to the alloy button staying molten for a long time which ensures a continuous flow of molten metal and proper solidification.

Induction Casting Machine:

- Melt the alloy in an electric induction furnace inside the crucible which is surrounded by water-cooled metal tubing.

- As the alloy reaches casting temperature in air or vacuum, it is cast into the mold by centrifugal force.

Direct Current Arc Melting Machine:

- Alloy is vacuum melted and is cast by pressure in an argon atmosphere.

- The direct current arc is produced between the two electrodes, i.e. alloy and water-cooled tungsten electrodes.

- Since the temperature in the arc exceeds 4000°C, the alloy melts quickly which is the major disadvantage.

Vacuum or Pressure-Assisted Casting Machine:

- Titanium and its alloys need a vacuum arc heating argon pressure casting machine.

- As the melting point of commercially pure titanium is 1671°C, so to prevent absorption of gases in a molten state, titanium should be cast in a protective atmosphere of argon or in a vacuum.

- Here a graphite or water-cooled copper crucible is used.

- Vacuum creates a negative pressure within the mold which helps to draw alloy in the mold.

Casting machines are also grouped based on the heating system, i.e.

- Torch melted

- Induction melted

- Arc melted.

- Torch melting: In this fuel used is the combination of natural or artificial gas; oxygen and acetylene gas.

- Induction melting: In this electrically conducting object is heated by electromagnetic induction. It is useful for melting high-fusing alloys, i.e. metal ceramic and base metal alloys.

- Arc melting: It melts industrial alloys such as steel. Direct current passes between two electrodes, i.e. a tungsten electrode and an alloy. It is used to melt high-fusion metals such as titanium.

Types Of Casting Defects

Question 12. Classify dental alloys used in dentistry.

Answer:

Classification of Dental Alloys

- According to use:

- Alloy for all metal and resin veneer restorations.

- Alloys for metal-ceramic restoration.

- Alloys for removable dentures.

- According to yield strength and percentage elongation:

- Type I: Soft

- Type II: Medium

- Type III: Hard

- Type IV: Extra-hard.

- According to nobility:

- High noble metal alloy: Containing > 40% Au and > 60 wt % of noble metals.

- Noble metal alloys: Contains > 25 wt % of noble metals.

- The predominantly base metal alloy contains: < 25 wt% of noble metals.

- According to major elements:

- Gold alloy

- Silver alloy

- Palladium alloy

- Nickel alloy

- Cobalt alloy

- Titanium alloys.

- According to three major elements:

- Gold: Palladium- silver

- Palladium: Silver-tin

- Nickel: Chromium-molybdenum

- Cobalt-chromium-molybdenum

- Iron-nickel-chromium

- Titanium-aluminium-vanadium.

- According to a number of alloys present:

- Binary: Two elements

- Ternary: Three elements

- Quaternary: Four elements.

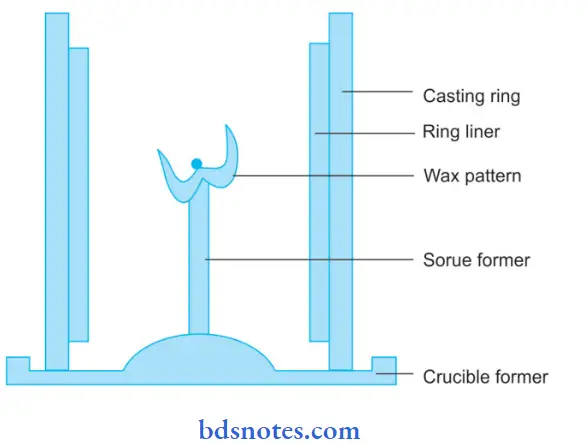

Question 13. Describe with a diagram various parts of a dental casting mold.

Answer:

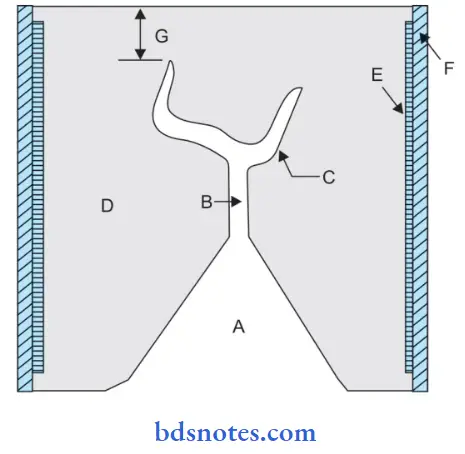

Following is the diagram of various parts of the dental casting mold:

- A.Crucible former

- B. Sprue

- C. Cavity formed by wax pattern after burnout

- D. Investment

- E. Liner

- F. Casting ring

- G. Recommended maximum investment thickness of approximately 6 mm

- Crucible former: It is a heat-resistant container in which alloy is melted prior to casting. It is made up of clay, carbon, quart, and ceramic.

- Sprue former: It is a device that provides a channel through which the molten alloy can reach the mold space in an invested ring after the wax has been eliminated.

- Following are the functions of sprue former:

- It forms a mount for the wax pattern.

- It creates a channel for the elimination of wax during burnout.

- It forms a channel for the entry of molten alloy during casting.

- It provides a reservoir for molten metal which compensates for alloy shrinkage during solidification.

- Wax pattern: It is the pattern of a final restoration which is made with type II inlay wax or other casting waxes with all precautions to avoid distortion. Before making the pattern a die lubricant is applied to help separate the wax pattern from the die.

- Investment: An investment is described as a ceramic material that is suitable for forming a mold in which molten metal or alloy is cast.

- Ring liner: A thin uniform sheet of material that is lined on the internal surface of the casting ring to facilitate the uniform expansion of the investment.

- The following are the functions of ring liner:

- It allows for mold expansion

- As the ring is transferred from the furnace to the casting machine it reduces heat loss as it is a thermal insulator.

- It permits easy removal of investment after casting.

- Casting ring: It is made up of corrosion-resistant alloys to withstand high temperatures and corrosion.

Dental Casting Alloy

Question 14. Define casting defects. Classify and enumerate in detail the different types of porosities and their causes.

Answer:

A casting defect is an irregularity in the metal casting process that is very undesirable.

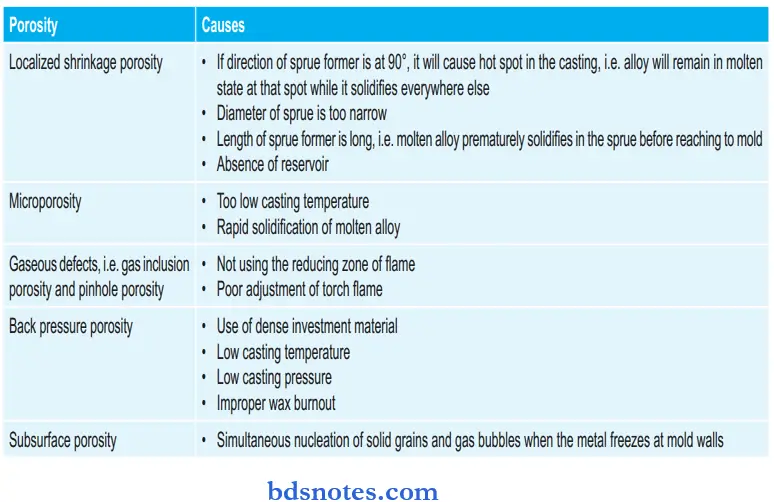

Classification and Enumeration of Different Types of Porosities:

1. Those caused by solidification shrinkage:

- Localized shrinkage porosity

- Suck back porosity (irregular in shape)

- Microporosities.

2. Those caused by gas.

- Pinhole porosity

- Gas inclusions (spherical in shape)

- Subsurface porosity.

3. Those caused by air traps in mold, i.e. back pressure porosity (see Table below).

Question 15. Write a short note on localized shrinkage porosity.

Answer:

Localized shrinkage porosity is also known as shrink spot porosity.

- It is one of the solidification defects.

- These are the irregular voids that are usually found near the sprue casting junction.

It occurs when the cooling sequence is incorrect and the sprue freezes before the rest of the casting. During a correct cooling sequence, the sprue should freeze last.

Dental Casting Alloy

This allows more molten metal to flow into the mold to compensate for the shrinkage of the casting as it solidifies. If the sprue solidifies before the rest of casting no more molten metal can be supplied from the sprue. The subsequent shrinkage produces voids or pits known as localized shrinkage porosity.

Shrink-spot porosity is avoided by:

- Using a sprue of the correct thickness.

- Attach the sprue to the thickest portion of the wax pattern.

- Flaring the sprue at the point of attachment or placing a reservoir close to the wax pattern.

Leave a Reply