Classification And Description Of Ceramic Systems

The ceramic restorations available today may be metal bonded or made completely of ceramic. Based on the substructure or core material used there are two basic groups. They are further divided based on the fabrication method.

1. Metal-ceramic (metal bonded or PFM) restorations

- Cast metal-ceramic restorations

- Cast noble metal alloys

- Cast base metal alloys

- Cast titanium (ultra-low fusing porcelain).

Read And Learn More: Basic Dental Materials Notes

- Burnished foil metal-ceramic restorations

- Capillary casting [sintered gold alloy foil coping Renaissance, Captek)

- Bonded platinum foil coping.

2. All ceramic restorations

- Platinum foil matrix condensed porcelain restorations

- Conventional feldspathic porcelain restorations

- Porcelain restorations with aluminous core

- Ceramic jacket crown with leucite-reinforced core (Optec HSP)

- Castable glass ceramics (Dicor)

- Pressable glass-ceramics

- Leucite-reinforced glass-ceramics (IPS Empress)

- Lithia disilicate reinforced glass-ceramics (IPS Empress 2)

- Glass-infiltrated core porcelains

- Glass infiltrated aluminous core (In-Ceram)

- Glass infiltrated spinel core (In-Ceram Spinell)

- Glass infiltrated zirconia core (In-Ceram Zirconia)

- Ceramic restorations from CAD/CAM ceramic blanks

- Feldspathic porcelain blanks (Vitablocs Mark II)

- Lithia disilicate glass-ceramic blanks (IPS e max CAD, Kavo)

- Glass infiltrated blanks (Alumina, Spinell, Zirconia)

- Partially sintered zirconia blanks (Vita In-Ceram YZ)

- Sintered zirconia blanks (Everest ZH blanks)

- Ceramic restorations from copy-milled ceramic blanks

- Alumina blocks (Celay In-Ceram)

- MgAl 2O4 blocks (In-Ceram spinel).

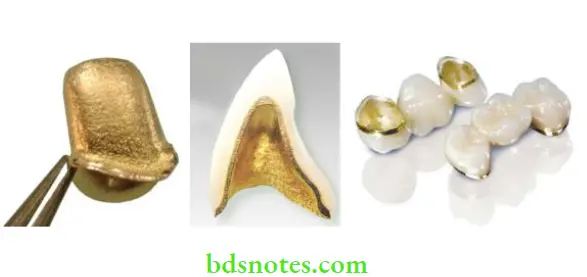

Metal-Ceramic Restorations

Synonyms Porcelain-fused-to-metal (PFM), metal-bonded restorations, ceramic metal, etc.

The early porcelain jacket crowns (PJC) did not use reinforcing cores and were therefore weak.

- The metal-ceramic restorations were developed around the same time Mclean introduced the aluminous core porcelains (1965).

- The cast metal core (called coping) or framework significantly strengthened the porcelain restoration and this soon became the most widely used ceramic restoration.

- According to a 1994 survey, 90% of all ceramic restorations were porcelain-fused-to-metal. The metal-ceramic systems are covered by ISO 9693.

The metal-ceramic system was possible because of some important developments.

- Development of metal and porcelain that could bond to each other

- Raising of the CTE of the ceramic in order to make it more compatible to that of the metal.

This obviously meant that a lot of research had to go into both porcelain and metal composition before they could be used for metal ceramics.

Types Of Metal-Ceramic Systems

As previously mentioned the metal-ceramic systems can be divided into

- Cast metal-ceramic restorations

- Cast noble metal alloys (feldspathic porcelain)

- Cast base metal alloys (feldspathic porcelain)

- Cast titanium (ultra-low fusing porcelain).

- Swaged metal-ceramic restorations

- Capillary cast [sintered gold alloy foil (Renaissance, Captek)]

- Bonded platinum foil coping.

Cast Metal-Ceramic Restorations

- The cast metal-ceramic restoration is hugely popular. Because of the strong metal frame, it is possible to make long-span fixed partial dentures.

- It can also be used in difficult situations where an all-ceramic restoration cannot be given because of high stresses and reduced preparation depth.

Cast Metal Uses

- Single anterior and posterior crowns.

- Short and long span anterior and posterior FDPs.

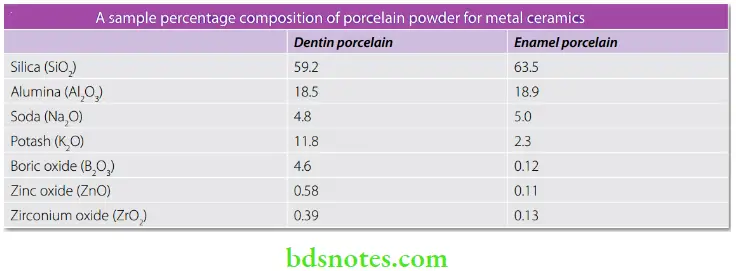

Composition Of Ceramic For Metal Bonding

- Feldspathic porcelains are used for metal bonding.

- The basic composition is quite similar to that of feldspathic porcelain described earlier except for the higher alkali content (soda and potash).

- The higher alkali content was necessary in order to raise the CTE.

- Unfortunately, this also increased the tendency of the ceramic to devitrify and appear cloudy. A typical composition is shown in.

- Special opaque porcelain is needed to mask the underlying metal so that it does not show through the ceramic.

- The opaquer has a high content of opacifiers. Similarly, the composition of glazes would be different. Glazes have a higher concentration of glass modifiers like soda, potash, and boric oxide.

Cast Metal Supplied As

- Enamel porcelain powders in various shades (in bottles)

- Dentin porcelain powders in various shades (in bottles)

- Liquid for mixing enamel, dentin, gingival and transparent

- Opaquer powders in various shades/ and liquids for mixing

- Gingival porcelain powder in various shades

- Transparent porcelain powder

- A variety of stain (color) powders

- Glaze powder

- Special liquid for mixing stains and glaze

Manipulation And Technical Considerations Construction Of The Cast Metal Coping Or Framework A wax pattern of the restoration is constructed and cast in metal. Metals used for the frame or coping include noble metal alloys, base metal alloys, and recently titanium (see chapter on casting alloys and casting procedures).

Metal Preparation

- A clean metal surface is essential for good bonding. Oil and other impurities from the fingers can contaminate.

- The surface is filled with ceramic bonded stones or sintered diamonds.

- Final texturing is done by sandblasting with an alumina air abrasive, which aids in bonding.

- Finally, it is cleaned ultrasonically, washed, and dried.

Degassing And Oxidizing

- The casting (gold porcelain systems) is heated to a high temperature (980°C) to burn of the impurities and to form an oxide layer which helps in the bonding.

- Degassing is done in the porcelain furnace.

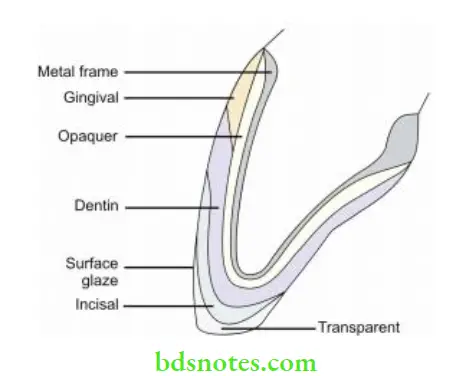

Opaquer

- The opaquer is a dense yellowish-white powder supplied along with a special liquid. The opaquer has two important functions.

- It is used to cover (mask) the metal frame and prevent it from being visible. It also aids in bonding the veneering porcelains to the underlying frame.

- The metal framework is held with a pair of locking forceps. Opaquer powder is dispensed onto a ceramic palette and mixed with the special liquid to a paste-like consistency.

- It is applied onto the metal frame with a brush and condensed. The excess liquid is blotted with tissue paper.

- The opaquer is built up to a thickness of 0.2 mm. The casting with the opaquer is placed in a porcelain furnace and fired at the appropriate temperature.

- Opaquer may be completed in two steps.

Condensation The process of packing the powder particles together and removing the excess water is known as condensation.

Purpose Proper condensation packs the particles together. This helps minimize porosity, improve strength, and reduce firing shrinkage. It also helps remove the excess water.

Condensation techniques

Vibration

- Mild vibration by tapping or running a serrated instrument on the forceps holding the metal frame helps to pack the particles together and bring out the excess water which is then blotted by an absorbent paper.

- An ultrasonic vibrator is also available for this purpose.

Firing of porcelains

- The process of sintering and fusing the particles of the condensed mass is known as filing. The powder particles flow and fuse together during firing.

- Making the restoration dense and strong. Firing is done in a porcelain furnace.

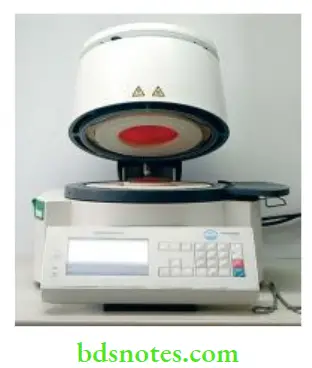

The Porcelain Furnace

- Firing is carried out in a porcelain furnace. There are many companies which manufacture furnaces.

- Modern furnaces are computer-controlled and have built-in programs to control the firing cycle. The programs can also be modified by the operator.

Firing Cycle

- The entire program of preheating, firing, subjecting to vacuum, subjecting to increased pressure, holding, and controlled cooling is known as a firing cycle.

- The firing cycles vary depending on the stage – opaquer filing, dentin firing, glaze firing, etc.

- The firing temperature is lowered gradually for each subsequent firing cycle.

- The opaquer has the highest temperature and the glaze has the lowest.

Preheating

- The condensed mass should not be placed directly into the hot furnace. This can cause a rapid formation of steam which can break up the mass.

- Modern furnaces have a mechanism whereby the work is gradually raised into the furnace. This is known as preheating.

Vacuum Firing

- During the filling of the porcelain, a vacuum (negative pressure) is created in the furnace. This helps to reduce the porosity in the ceramic.

- The vacuum is later released raising the pressure in the furnace. The increased pressure helps to further reduce the size of any residual air bubbles not eliminated by the vacuum.

- The vacuum is not activated during the glaze firing.

Cooling

- The cooling of the fired porcelain should be well controlled. Rapid cooling can cause the porcelain to crack or it can induce stresses inside which weaken the porcelain.

- Cooling is done slowly and uniformly and is usually computer-controlled.

Spatulation A small spatula is used to apply and smoothen the wet porcelain. This helps to bring out the excess water.

Dry powder Dry powder is placed on the side opposite a wet increment. The water moves towards the dry powder pulling the wet particles together.

Dentin And Enamel

- The dentin powder (pink powder) is mixed with distilled water or the supplied liquid.

- A glass spatula should be used (ceramic powder is abrasive and can abrade the metal and contaminate the porcelain).

- The bulk of the tooth is built up with dentin. A portion of the dentin in the incisal area is cut back and enamel porcelain (white powder) can be added building the restoration.

- After the build-up and condensation is over, it is returned to the furnace for sintering.

Additions

- It is not necessary to build up the restoration in one step.

- Large or difficult restorations may be built up and fired in two or more stages.

- After each firing the porcelain may be shaped by grinding and additional porcelain is placed in deficient areas.

- Each additional firing is done at a lower temperature.

- Caution The restoration should not be subject to too many filings. Excessive filings can give rise to an over-translucent, lifeless restoration.

Gingival And Transparent Porcelain

- The enamel of some natural teeth may appear transparent.

- This is usually seen near the incisal edges. If present it can be duplicated using transparent porcelain.

- The cervical portions of natural teeth may appear darker (for example more yellow) than the rest of the tooth.

- When indicated cervical porcelains are used to duplicate this effect (they are also referred to as gingival or neck dentin).

Surface Staining, Characterization, And Effects

- Natural teeth come in a variety of hues and colors.

- Some of them are present at the time of eruption (intrinsic, for example, white fluorosis stains), while others are acquired over a period of time, etc.).

- Staining and characterization help make the restoration look natural and help it blend in with the adjacent teeth.

- The stain powders are mixed with a special liquid, applied, and blended with a brush.

- With more and more emphasis on recreating the natural look, effects are created using special techniques.

- This includes defects, cracks, or other anomalies within the enamel.

Glazing

- Before final glazing, the restoration is tried in the mouth by the dentist. The occlusion is checked and adjusted by grinding.

- Final alterations can be made to improve the shape of the restoration.

- After all changes have been completed the restoration is ready for glazing. The restoration is smoothened with a fine stone prior to glazing to remove gross scratch marks.

- Glazing provides a smooth glossy surface for restoration.

Objectives of glazing

- Glazing enhances esthetics.

- Enhances hygiene.

- Improves strength.

- Glazed porcelain is much stronger than unglazed ceramic.

- The glaze inhibits crack propagation.

- Reduces the wear of opposing teeth. The rough surface on unglazed porcelain can accelerate the wear of the opposing natural teeth.

Glazing versus conventional polishing

- Porcelain can be polished using special abrasives. Porcelain is an extremely hard material and is quite difficult to polish.

- Glazing is considered by some to be superior to conventional polishing.

Glazing Types

- Overglaze The glaze powder is mixed with the special liquid and applied to the restoration.

- The filling temperature is lower than that of the body porcelain.

- The firing cycle does not usually include a vacuum.

- The chemical durability of overglaze is lower because of the high flux content.

- Self-glaze A separate glaze layer is not applied.

- Instead, the restoration is subject to controlled heating at its fusion temperature.

- This causes only the surface layer to melt and flow to form a vitreous layer resembling a glaze.

Porcelain-Metal Bond

Falls into two groups

- Chemical bonding across the porcelain-metal interface.

- Mechanical interlocking between porcelain and metal.

Porcelain-Metal Bond Chemical Bonding

- Currently regarded as the primary bonding mechanism.

- An adherent oxide layer is essential for good bonding. In base metal alloys, chromic oxide is responsible for the bond.

- In noble metal alloys, indium, tin oxide, and possibly iridium oxide do this role.

- Both inadequate oxide formation and excessive oxide build-up can lead to a weak bond resulting in the delamination of the overlying porcelain.

Porcelain-Metal Bond Mechanical Interlocking

- In some systems, mechanical interlocking provides the principal bond.

- Sandblasting is often used to prepare the metal surface.

- The presence of surface roughness on the metal oxide surface improves retention, especially if undercuts are present.

- Wettability is important for bonding.

Advantages And Disadvantages Of Metal-Ceramic Restorations

Advantages

- Better fracture resistance because of the metal reinforcement.

- Better marginal fit because of the metal frame.

Disadvantages

- Poor esthetics when compared to all-ceramic restorations because the underlying metal and opaque reduce the overall translucency of the tooth.

- The metal frame and the lack of translucency sometimes show through the gingiva resulting in the characteristic dark margins.

Other Metal-Ceramic Systems Capillary Cast (Sintered Gold Alloy Foil-Ceramic) Restorations

- Adapting and sintering gold alloy foils (Renaissance and Captek) is a novel way of making a metal frame without having to cast it.

- The system was developed by Shoher and Whiteman and introduced to the dental community in 1993. Captek is an acronym for ‘capillary casting technique’.

- The technique is used to make crowns and field prostheses using proprietary materials and techniques. (Refer chapter on ‘casting procedures’ for additional information).

Composition, mode of supply, and capillary casting

- They are supplied as thin strips in two forms called Captek P and Captek G. Captek P (Platinum/ Palladium/ Gold) has a porous structure and serves as the internal reinforcing skeleton.

- Captek G is 97.5% Gold and 2.5% Silver. On heating in a furnace, the Captek P acts like a metal sponge and draws in (capillary action) the hot liquid gold completely into it.

- Captek G provides the characteristic gold color of this system. The first coping can be described as a composite structure.

Capillary Cast Technique

The technique for fabrication is described in the chapter ‘Casting procedures’.

Capillary Cast Advantages

- The thinner foil alloy coping allows a greater thickness of ceramic, thereby, improving the esthetics.

- The gold color of the alloy improves the aesthetics of the restoration.

- Less reduction of tooth structure.

- The nonesthetic high-intensity high-value opaquer layer seen with conventional metal ceramics is eliminated.

Bonded Platinum Foil—Ceramic Crowns

- A platinum foil coping is adapted onto the die.

- To improve the bonding of the ceramic to the platinum foil coping, an electrodeposition technique is used.

- A thin layer of tin is electrodeposited onto the foil and then oxidized in a furnace.

- The advantages of using bonded platinum foil are similar to that of swaged gold alloy foil.

The electrodeposition technique

- This is a technique used to improve both esthetics and bonding. A layer of pure gold is electrodeposited onto the metal.

- This is followed by a quick minimal deposition of tin over the gold.

Bonded Platinum Foil Advantages

- The gold color enhances the vitality of the porcelain, thereby, enhancing esthetics (the normal technique requires a heavy unesthetic opaque layer to cover the dark metal oxide surface).

- The tin helps in chemical bonding (through the formation of tin oxide).

- Improves wetting at the gold-porcelain interface thereby reducing porosity.

- The electrodeposition technique can be used on metals, such as stainless steel, cobalt chromium, titanium, and other non-gold and low-gold alloys.

All-Ceramic Restorations

The all-ceramic restorations are made without a metallic core or sub-structure. This makes them esthetically superior to metal-ceramic restoration. Unfortunately, all-ceramic restorations had lower strength, thus, metal-ceramics continued to be the restoration of choice for the majority of restorations till the 1990s.

- Continued research has led to improved all-ceramic systems with greater strength and fracture resistance.

- Manufacturers today claim the new generation all-ceramic materials are capable of producing not only single crowns but anterior and even posterior all-ceramic FDPs as well.

- Long-span FDPs have also been attempted.

The all-ceramic restorations are grouped according to their type and method of fabrication

- Condensed sintered

- Traditional feldspathic porcelain jacket crown

- Porcelain jacket crown with aluminous core (Hi-Ceram)

- Ceramic jacket crown with leucite-reinforced core (Optec HSP).

- Cast glass ceramics (Dicor).

- Injection molded (leucite reinforced) glass ceramic (IPS Empress).

- Slip-cast glass infiltrated ceramics

- Glass infiltrated aluminous core restorations (In-Ceram)

- Glass infiltrated spinal core restorations (In-Ceram Spinell)

- Glass infiltrated the zirconia core (In-Ceram Zirconia).

- Milled ceramic restoration or cores

- CAD/CAM restorations

- Copy milled restorations

(Blocks or blanks of various ceramics are machined to form the restoration. Examples are alumina, zirconia, lithia disilicate, etc. The various types are detailed in a subsequent section – see classification of machinable ceramics).

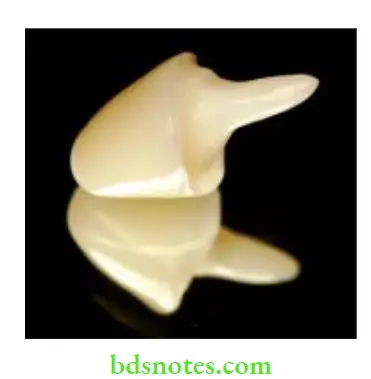

Porcelain Jacket Crown

These are crowns made entirely of feldspathic porcelain. They are constructed on a platinum foil matrix which is subsequently removed.

Porcelain Jacket Crown Types

- Porcelain jacket crown (traditional).

- Porcelain jacket crown with an aluminous core.

- Porcelain jacket crown with leucite-reinforced core (Optek HSP).

Note The above two are generally referred to as ‘porcelain jacket crowns’ or PJCs. The subsequently introduced ceramics are referred to as ‘ceramic jacket crowns CJCs’and ‘glass ceramic crowns’.

Traditional Porcelain Jacket Crown

- The all-porcelain crown (PJC) has been around for a century (the early 1900s).

- These early crowns are also referred to as traditional or conventional PJCs.

- They were made from conventional high-fusing feldspathic porcelains.

- As mentioned before these were very brittle and fractured easily (half-moon fractures).

- The marginal adaptation was also quite poor. Because of these problems they gradually lost popularity and are no longer used presently.

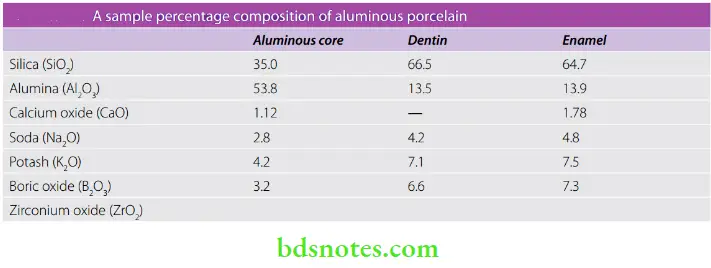

Porcelain Jacket Crown With Aluminous Core

- The problems associated with traditional PJCs led to the development of the PJC with an alumina-reinforced core (McLean and Hughes, 1965).

- The increased content of alumina crystals (40 to 50%) in the core strengthened the porcelain by interrupting of crack propagation.

- In spite of the increased strength they were still brittle and therefore not indicated for posterior teeth and their use was restricted to anterior teeth.

- The composition of the alumina-reinforced PJC is shown in Table.

Technical considerations The porcelain jacket crowns are made using the platinum foil matrix technique.

Platinum foil matrix

- A platinum foil is adapted to the die with a wooden point.

- The platinum foil functions as a matrix. It supports the porcelain during condensation and filing.

Condensation and filing

- The core porcelain is carefully condensed onto the foil. The foil with the condensed porcelain is carefully removed from the die.

- It is then placed in the furnace and fired. After cooling, the rest of the crown is built up with conventional feldspathic porcelain.

Removing the foil After completion of the restoration, the platinum foil is gently teased out and discarded. This can be quite difficult.

Leucite Reinforced Porcelain

Optec HSP is a feldspathic porcelain with a higher leucite crystal content (leucite reinforced). Its manipulation, condensation, and firing is quite similar to the alumina-reinforced porcelain jacket crowns (using a platinum foil matrix).

Leucite Reinforced Porcelain Uses Inlays, onlays, veneers, and low-stress crowns.

Leucite Reinforced Porcelain Advantages

- They are more esthetic because the core is less opaque (more translucent) when compared to aluminous porcelain.

- Higher strength.

- No need for special laboratory equipment.

Leucite Reinforced Porcelain Disadvantages

- Fit is not as good as metal-ceramic crowns.

- Potential marginal inaccuracy.

- Not strong enough for posterior use.

Castable Glass Ceramic

The castable glass ceramic is quite unlike the previously mentioned porcelains.

- Its properties are more closer to that of glass and its construction is quite different.

- This is the only porcelain restoration made by a centrifugal casting technique.

- The subsequent ‘cramming’ process is also quite unique to this porcelain.

- Cramming enhances the growth of mica crystals within the ceramic.

Glass Ceramics

Glass-ceramics are materials that are formed initially as glass and then transformed into ceramics usually by controlled heat treatment.

- The heat induces partial devitrification (crystallization within the glass) which increases the strength as well as improves esthetics by making it less transparent and more tooth-like.

- The glass-ceramics used in dentistry include castable, machinable, and hot-isostatically pressed glass ceramics.

Castable Glass Ceramic Supplied As

- The first commercially available castable glass-ceramic for dental use was ‘Dicor’ developed by Corning Glass Works and marketed by Dentsply.

- They are supplied as glass ingots. A recrystallized form called Dicor MGC is also available as machinable blanks for CAD/CAM.

Castable Glass Ceramic Composition Dicor glass-ceramic contains 55 vol% of tetra silicic Formica crystals.

Castable Glass Ceramic Features

- The Dicor glass-ceramic crown is very esthetic.

- This is because of its greater translucency (unlike some other porcelains which have more opaque cores).

- It also picks up some of the colors from the adjacent teeth (chameleon effect) as well as from the underlying cement.

- Thus the color of the bonding cement plays an important role.

Castable Glass Ceramic Uses Inlays, onlays, veneers, and low-stress crowns.

Fabrication Of A Dicor Crown

- To understand the salient features of this material, the step-by-step construction of a crown will be described

- The pattern is first constructed in wax and then invested in refractory material like a regular cast metal crown.

- After burning out the wax, nuggets of Dicor glass are melted and cast into the mold in a centrifugal casting machine.

- The glass casting is carefully recovered from the investment by sandblasting and the sprues are gently cut away.

- The glass restoration is then covered with an embedment material to prepare it for the next stage called cramming.

- Cramming is a heat treatment process by which the glass is strengthened. Cramming results in the development of microscopic crystals of mica, which

- Improves the strength and toughness of the glass

- Improves the esthetics of the restoration (it reduces the transparency of the glass making it more opaque and less glass-like).

- The cramped glass can be built up with special veneering porcelain and fired to complete the restoration. Surface stains may be applied to improve the esthetics.

Castable Glass Ceramic Advantages

- Ease of fabrication.

- Good esthetics (greater translucency and chameleon effect).

- Improved strength and fracture toughness.

- Good marginal fi.

- Very low processing shrinkage.

- Low abrasion of opposing teeth.

Castable Glass Ceramic Disadvantages

- Inadequate strength for posterior use.

- Internal characterization is not possible. Has to be stained externally to improve esthetics.

Heat Pressed Ceramics

This is another ceramic material that again is quite unlike the previous ceramics because of its unique way of fabrication (injection molding). It is a programmed glass-ceramic having a high concentration of reinforcing crystals.

- The material supplied in the form of ingots is softened under high temperatures and forced into a mold created by a lost wax process.

Synonyms Injection is molded or Heat-pressed glass-ceramics.

Types And Mode Of Supply Heat-pressed ceramics are supplied as ingots of various compositions.

These include

- Heat-pressed glass ceramics

- Leucite or KAlSi2O6 reinforced (IPS Empress, Finesse, Optimal, Cerpress, etc).

- Lithium disilicate reinforced (IPS empress 2, OPC 3G).

- Heat-pressed veneering ceramics [for example IPS ZirPress, Vita PM9] are available for use as a pressed layer over machined zirconia cores.

Compatible veneering ceramics in powder-liquid form may be provided along with the ingots or acquired separately.

Heat-Pressed Ceramics Uses Inlays, onlays, veneers, and low-stress crowns. Small 3-unit FDPs may be constructed with IPS Empress 2.

Microstructure

- IPS Empress—contains 35 to 40% vol of leucite crystals.

- IPS Empress 2—consists of 65 to 70% by volume of interlocked elongated lithia disilicate crystals. The crystal size varies from 0.5 to 4 µm in length.

- The crystals within the structure improve the fracture resistance by reducing crack propagation.

Fabrication

- The wax patterns of the restorations are invested in refractory material and heated to 850 °C in a furnace to burn the wax and create the mold space.

- It is then transferred to the pressing furnace.

- A ceramic ingot and an alumina plunger are inserted into the sprue.

- Pressing temperature for IPS Empress—1075 to 1180 °C

- Pressing temperature for IPS Empress 2—920 °C

- The pressing is done under an air pressure of 1,500 psi.

- The core or restoration is retrieved from the flask.

- Compatible veneering porcelains are added to the core to build up the final restoration

- It can also be directly fabricated as a crown in which case, the crown is stained and glazed directly.

Heat Pressed Ceramics Advantages

- Better fi (because of lower firing shrinkage).

- Better esthetics due to the absence of metal or an opaque core.

Heat-Pressed Ceramics Disadvantages

- Need for costly equipment.

- The potential of fracture in posterior areas.

Glass Infiltrated Ceramics

These are specialized core ceramics reinforced by a unique glass infiltration process. They are also sometimes referred to as slip-cast ceramics.

Glass Infiltrated Ceramics Types Currently, there are three types depending on the core material used.

- Glass infiltrated alumina core (In-Ceram Alumina).

- Glass infiltrated the spinal core (In-Ceram Spinell).

- Glass infiltrated the zirconia core (In-Ceram Zirconia).

Glass Infiltrated Ceramics Supplied as Oxide powder (alumina, spinel, or zirconia) with mixing liquids, glass powder, and veneering ceramics

Glass Infiltrated Alumina Core

This ceramic system has a unique glass infiltration process and is the first of its kind claimed for anterior FDP fabrication.

- The glass infiltration process compensates for firing shrinkage.

- The final core after completion of the glass infiltration is made up of about 70% alumina and 30% (sodium lanthanum) glass.

Glass-Infiltrated Alumina Core Indications

- Anterior and posterior crowns, and

- Short span anterior fixed dental prostheses.

Glass Infiltrated Alumina Core Composition

Fabrication

- Two dies are required. One in stone and the other in refractory die material.

- Preparing the slip—A measured quantity (38 g) of alumina powder is added slowly into a beaker containing 1 ampoule of mixing liquid and a drop of additive liquid. Mixing is done with the help of a special ultrasonic unit (Vitasonic).

- The water in the Vitasonic should be chilled using ice cubes. The prepared slip should be smooth and homogenous.

- The slip is applied to the refractory die using the slip cast method (the water from the slurry is absorbed by the porous die leaving a dense layer of alumina on the surface).

- Once started the slip should not be allowed to dry out before the coping is completed. The process is continued until an alumina coping of sufficient thickness is obtained.

- The fragile slip-cast alumina coping is dried at 120 °C for 2 hours.

- The coping is sintered (Inceramat furnace) for 10 hours at 1120 °C.

- After sintering the copings are tested for cracks using a special dye.

- The next step is glass infiltration. Glass powder is mixed with distilled water. One or two thick coats (1-2 mm) is applied onto the sintered alumina coping (outer surface only) and fied for 2-3 hours at 1110 °C on a platinum foil. The glass melts and infiltrates into the porous alumina coping through capillary action.

- The excess glass forms a glassy layer on the surface which is trimmed of using special diamond burs, followed by sandblasting. A glass control firing (1000 °C) is carried out.

- The coping is then built up using special veneering ceramics (Vita VM 7).

Glass Infiltrated Alumina Core Advantages

- Good fit and marginal adaptation.

- Good strength when compared to the earlier ceramic crowns. Claimed to be strong enough for posterior single crowns and anterior FDP use.

Glass Infiltrated Alumina Core Disadvantages

- Comparatively less esthetic because of the opacity of the alumina core.

- Quite tedious to fabricate.

- Not all the FDPs were successful, a few of them did fracture occasionally.

Glass-Infiltrated Alumina Core Uses

- In addition to inlays, onlays, veneers, and low-stress (anterior and posterior) crowns, this material can be used to construct low-stress anterior FDPs.

- Because of its occasional tendency to fracture when used for FDP construction, its use should be carefully selected.

- For people allergic to metal-based restorations.

- Where esthetics is absolutely critical.

Glass Infiltrated Spinell Core

In-Ceram Spinell is an offhoot of In-Ceram Alumina.

Because of the comparatively high opacity of the alumina core, a new material was introduced known as In-Ceram spinel.

- It uses spinel (MgAl2O4) instead of alumina.

- The fabrication process is quite similar to that for In-Ceram Alumina.

- The In-Ceram Spinell is more translucent and therefore more esthetic compared to the InCeram Alumina core.

- Since the strength is lower, its use is limited to low-stress situations.

Glass-Infiltrated Spinell Core Indications Its high translucency makes it a material of choice for crowns and restorations in esthetic (anterior crowns) and stress-free zones.

Glass Infiltrated Spinell Core Contraindications

- The high translucency contraindicates it in situations where the underlying tooth structure is severely discolored and needs to be masked.

- Its low strength also contraindicates it for posterior situations and FDPs.

Glass Infiltrated Zirconia

Zirconia (ZrO2) is a naturally occurring mineral. Crystals of Zirconia are used as a substitute for diamonds.

- In-Ceram Zirconia is the strongest of the three glass-infiltrated core materials.

- The final glass-infiltrated ICZ cores contain around 30 wt% zirconia and 70 wt% aluminas.

Glass-Infiltrated Zirconia Indications

- Its high strength makes it a material of choice for posterior crowns and short-span fixed partial dentures in high-stress areas (posterior FDPs).

- It is not particularly suited for esthetic zones because of its greater opacity.

- However, in cases where there is severe discoloration, In-Ceram Zirconia helps mask the discolored tooth structure because of its greater opacity.

CAD/CAM Ceramics

Constructing a dental ceramic restoration is technique-sensitive, labor-intensive, and time-consuming.

- Machined ceramics were introduced to overcome some of these problems.

- They are also known as milled or machined ceramics.

Machinable ceramic systems can be divided into two categories

- CAD/CAM systems

- Copy milled systems

CAD/CAM Systems

- These are systems that can design and produce restorations out of blocks or blanks of ceramics with the aid of a computer.

- CAD/CAM is an acronym for computer-aided design-computer-aided manufacturing.

History Of CAD/CAM

- The major development in the field of dental CAD/CAM took place in the 1980s. They were influenced by three important pioneers.

- The first was Duret who fabricated crowns through a series of processes starting with an optical impression of the prepared tooth.

- The milling was done by a numerically controlled milling machine (the precursor of modern CAM/CAM).

- The second pioneer was Mörmann, developer of the CEREC system at the University of Zurich.

- A compact chair-side machine milled the crown from measurements of the preparation taken by an intraoral camera.

- At the time, the system was innovative as it allowed ‘same-day restorations’.

- With the announcement of this system, the term CAD/CAM spread rapidly to the dental profession.

- The third was Andersson, the developer of the Procera system in the 1980s.

- The Japanese also developed many systems in the 1980s but these were not commercially successful because of the resistance from health insurance companies.

- The early systems had to overcome many problems including limited computing power, poor marginal accuracy, etc.

- Current CAD/CAM systems have come a long way. With improvements in technology, material, and software, restoration fabrication is considerably more accurate and operator friendly as well. CAD/CAM systems are now part of everyday dentistry.

Commercially available CAD/CAM systems

- Many systems are currently available using a variety of techniques and materials.

- Some examples of commercially available

CAD/CAM systems are –

- Cerec (Sirona),

- Sirona InLab,

- Everest (Kavo),

- Cercon (Dentsply),

- Lava (3M ESPE), Zeno (Weiland),

- 5-tec (Zirkonzahn), etc.

Essentials Of A CAD/CAM System The CAD/CAM system consists of 5 essentials

- Scanner or digitizer – Virtual impression

- Computer – Virtual design (CAD)

- Milling station – Produces the restoration or framework

- Ceramic blanks – Raw material for the restoration

- Furnace – For post-sintering, cramming, etc.

Combining Various Porcelains And Processing Techniques

In some systems, the entire restoration can be made entirely from the same material.

- Example – An inlay or laminate may be constructed entirely with pressable ceramics or from a machined feldspathic block.

- In many systems, at least 2 or more processing techniques and materials have to be combined to produce the final restoration for a variety of reasons like esthetics, ease of fabrication, need for correction, etc.

Most reinforced core ceramics are too opaque to be used to construct the entire restoration it. These cores have to be built up with veneering ceramics, characterized with stains and then glazed to produce the final restoration.

- Example 1—Glass infiltrated cores are too opaque and have to be layered with condensing-type veneering porcelains to produce the final restoration.

- Example 2—Machined alumina cores are frequently built up with condensable ceramics.

- Example 3—In one system machined zirconia blocks are overlayed with a pressable veneering material (Zir Cad and Zir Pres). An important point to remember is that various ceramics should be compatible with each other when used together.

Non- Non-compatible products may have differences in CTE which can cause the failure of the restoration. The manufacturers usually specify the veneering materials compatible with their products.

Scanner Or Digitizer

The dimensions of the prepared tooth (or die or wax pattern) are picked up and digitized in order to create a 3-dimensional image of the prepared tooth in the computer. This is achieved by scanning the preparation or the die.

The 2 types of digitizers currently employed are

- Contact probes Physically contact the die as it moves along its surface while transmitting the information to the computer. example Procera Forte contact scanner.

- Scanners Unlike contact probes, scanners are optical devices. These include

- Intraoral hand-held wands. These are chairside scanners.

- The intraoral scanner reflects light (visible light, laser, or LED) and

- Captures it with a camera to create an optical impression of the prepared tooth and adjacent structures.

- Multiple images have to be captured to stitch together a composite 3D image in the computer.

- In some systems, a special powder is dusted to reduce reflection and improve readability.

- Laboratory scanners These are larger devices that scan the cast or die using different technologies.

- Some use a camera to capture multiple images similar to the intraoral scanner (white light optical scanner).

- Others use 2 cameras to capture the object from multiple angles using white light or laser planes projected in a grid pattern.

- The Procera optical scanner uses a laser beam to measure distances (conoscopic holography).

Computer -CAD process

The restoration or the core is designed in the computer. Most manufacturers have their own software for the CAD process.

- The CAD process aids in designing either the restoration, coping or the FDP substructure. The computer can automatically detect the finish line.

- Some use a library of tooth shapes that is stored on the computer to suggest the shape of the proposed restoration.

- A recording of the bite registration (the imprint of the opposing or antagonist tooth in a wax-like or rubbery material) is also added to the data.

- The combined information together with the 3D optical impression of the prepared tooth establishes the approximate zone in which the new restoration can exist.

- The proposed restoration can then be morphed to fi into this zone in an anatomically and functionally correct position.

- The dentist can make corrections or modify the design if required and then send it to the milling unit for completion.

Milling Station

Milling stations have evolved considerably since they were first introduced into the market.

- The earlier models ground only the internal surface.

- The external surface had to be manually ground.

- Current CAD/CAM machines can grind the external surface also.

- Signals from the computer control the milling tool which shapes the ceramic block according to the computer-generated design.

- To begin the process the ceramic block is attached to the machine via a frame or built-in handle(s).

- The enlargement factor (see pre-sintered zirconia) is also calculated where applicable.

- Milling is performed by a diamond or carbide milling tool.

- The Cerec station uses 2 diamond burs to grind the internal and external surfaces simultaneously.

- Other machines use a single tool that moves along multiple axes (3 to 5 axis) and performs the milling action.

- The Everest (Kavo) Engine is an example of a 5-axis milling action. Some machines (Kavo Everest) can mill both ceramic and titanium.

Ceramic blanks

A variety of ceramic blanks in various sizes, shades, and shapes are available for milling. Multiple units can be produced from the larger blocks.

- The smaller blanks may produce only a single coping or restoration.

- The blank is attached via a frame to the machine or by one or more handles on the blank itself.

Classification Of Machinable Ceramic Blanks

- Feldspathic porcelain blanks [Vitablocs Mark II (Vita)].

- Glass-ceramic blanks

- Tetrasilicic flormica based glass ceramic [Dicor MGC (Dentsply)]

- Leucite-based [ProCad (Ivoclar), Everest G (Kavo)]

- Lithia disilicate glass-ceramic [IPS e max CAD (Kavo)].

- Glass infiltrated blanks

- Alumina (Vita In-Ceram Alumina)

- Spinell (Vita In-Ceram Spinell)

- Zirconia (Vita In-Ceram Zirconia).

- Presented blanks

- Alumina (Vita In-Ceram AL)

- Yttria stabilized Zirconia (Vita In-Ceram YZ).

- Sintered blanks

- Yttria stabilized Zirconia (Everest ZH blanks).

Brief description of various materials for CAD/CAM

- The fabrication process is system and material-specific.

- The prepared tooth or teeth is scanned directly from the mouth or from a model made from a regular impression.

- Next, the restoration or substructure is designed on the computer.

- The blank is attached to the milling station and the bar code is scanned.

- The time taken for milling depends on the size and complexity of the restoration as well as the material used.

- For example, pre-sintered zirconia is easier to mill than sintered zirconia. It also reduces the wear of the milling tools.

- After milling, the structure is separated from the blank using water-cooled cutting and grinding discs or burs.

- Subsequent processing procedures are then initiated depending on the material and system used.

Feldspathic blanks

- Feldspathic restorations can be milled to full contour.

- The restoration is glazed after milling. Optional processing includes veneering and staining.

- CAD/CAM Uses – inlays, laminates, and anterior crowns.

Leucite reinforced

- These blanks can be milled to full contour.

- The restoration is glazed after milling. Optional processing includes veneering and staining.

- Leucite reinforced Uses – inlays, onlays, laminates, and anterior crowns.

Lithium disilicate

- The ceramic is machined in an intermediate crystalline state in which the material shows its characteristic bluish shade.

- In this stage, the material is easier to shape and can be tried in the mouth.

- This is followed by a simple, quick crystallization process (30 minutes) in a conventional ceramic oven in which it reaches its final strength and the desired esthetic properties such as tooth color, translucence, and brightness.

- Optional processing includes veneering and staining.

- Lithium disilicate Uses – inlays, onlays, and anterior and posterior crowns.

Glass infiltrated ceramics

- These are usually machined as cores or FDP substructures. Subsequent processing includes glass infiltration, veneering, and glazing.

- Glass infiltrated ceramics Uses In-Ceram Spinell is recommended for anterior single crowns copings.

- In-Ceram Alumina is indicated for anterior and posterior crowns and 3 unit anterior FDP substructures.

- In-Ceram Zirconia can be used for anterior and posterior crowns and 3-unit FDP substructures.

Presented zirconia Fully dense zirconia is extremely difficult to machine, taking up to two hours just to fabricate a single unit. Therefore, most restorations with zirconia frameworks are fabricated by machining a porous or partially fied block of zirconia known as pre-sintered zirconia.

- These are usually used as cores for crowns or FDPs. In the pre-sintered condition, they are usually softer and easier to mill.

- They are milled to a slightly (20%) larger size, to compensate for the subsequent sintering shrinkage.

- Following milling they have to be sintered (called post sintering). Sintering is done in a furnace. Sintering time and temperature varies between brands.

- Sintering time – 6 to 7.5 hours

- Sintering temperature – 1350 to 1530 °C

- Because of the high temperatures involved special furnaces are required for zirconia sintering. All grinding and adjustments should be completed prior to sintering.

- Adjustments following post-sintering should be done with water-cooled, vibration-free, fine diamonds.

- The restoration may be immersed in a special coloring liquid to improve the aesthetics. The restoration is then built up with compatible veneering ceramics.

Presented zirconia Uses core construction for crowns and long-span anterior and posterior FDPs. (Zirconia is described in greater detail in a subsequent section).

Sintering Furnaces

Furnaces are an important part of CAD/CAM dentistry. A variety of furnaces are available depending on the type of blank used. For example, In-Ceram alumina blanks have to be glass infiltrated in a furnace following machining.

- Leucite or lithia disilicate blanks have to be crammed to induce partial crystallization.

- The furnace for the sintering of zirconia is highly specialized as it involves very high temperatures.

- Zirconia sintering can involve temperatures greater than 1500 °C.

Copy Milled Systems

Some systems use a copy-milling technique to produce ceramic cores or substructures for FDPs.

In copy milling a wax pattern of the restoration is scanned and a replica is milled out of the ceramic blank (see Table for comparison of CAD/CAM and copy milling).

Commercial systems available Examples of commercially available copy-milling systems are

- Celay (Mikrona AG, Spreitenbach, Switzerland).

- Cercon (Degudent, Dentsply). Cercon has both CAD/CAM and copy-milling systems.

- Ceramill system.

Fabrication of a copy-milled restoration substructure The Cercon system will be described.

- A stone die is prepared from the impression of the preparation.

- A pattern of restoration is created using wax.

- The pattern is found on the left side of the milling machine (Cercon Brain).

- A pre-sintered zirconia blank is attached to the right side (milling section) of the machine.

- The machine reads the bar code on the blank which contains the enlargement information.

- On activation, the pattern on the left side is scanned (noncontact optical scanning) while.

- The milling tool on the right side mills out the enlarged replica (30% larger) of the pattern from the attached ceramic blank.

- The milled structure is removed from the machine and sectioned of from the frame.

- Any remaining attachment stubs are trimmed and final adjustments are made.

- The zirconia structure is then placed in a sintering furnace (Cercon Heat) and fied for 6 hours at 1350 °C to complete the sintering process.

- The restoration is completed using compatible veneering porcelains.

Ceramill system

Unlike the earlier system, the Ceramill system is based on the pantograph type of copy milling which, according to the company, “puts the material back in the hands of the technician”.

- To create a zirconia coping, the user applies a light-cured resin over a traditional die, attaches the resin pattern into a plastic plate, and inserts it into the milling unit, side by side with a YtZP zirconia blank.

- The unit has two conjoined arms that hold the probe tip and the milling handpiece.

- The user manually traces the resin buildup with the probe tip while the other arm simultaneously mills a duplicate coping out of the zirconia block.

Networked CAD Or CAM Production

The Procera system by Nobel Biocare is a unique system where restorations are produced using information sent via the Internet. In this system, the impression is sent to a local Nobel-licenced laboratory.

- Here the impression is poured and the conventional die is scanned by a contact scanner [Procera Forte].

- The coping is designed (CAD) and together with the dimensions of the scanned die, the information is passed via the internet to a fully automated industrial-scale remote production facility which may be in another country.

- Here an enlarged die is milled via the CAM process. The core is produced by dry pressing on to the die and is followed by sintering.

- The sintered copings are individually checked for quality control and shipped to the laboratory of origin where the subsequent veneering is completed.

- Thus in this system, the laboratory needs to invest only in the scanner and the CAD software

Yttria Stabilized Zirconia Ceramics

Zirconium is one of the most abundant elements in the earth’s crust. Zirconia is the oxide of zirconium metal (ZrO2).

- Zirconium oxide is a white crystalline oxide ceramic with unique properties.

- Its most naturally occurring form is the rare mineral, baddeleyite. A form of cubic zirconia is popularly used as a diamond simulant.

Yttria Stabilized Zirconia Ceramics Transformation toughening

- It has the highest strength among dental ceramics because of its high degree of crack resistance.

- This is possible because of a unique property of zirconia to undergo a process known as transformation toughening.

- The stable form of zirconia is the monoclinic form. When zirconia is heated, it changes to its tetragonal high-temperature phase which again reverts back to the monoclinic form on cooling.

- However, the addition of yttrium oxide (3–5%) also known as yttria maintains the zirconia in its high-temperature tetragonal form at room temperature.

- Thus, this form of zirconia is known as ‘yttria-stabilized zirconia polycrystal’.

- When stress is applied to the zirconia as in the beginning of a crack formation, it reverts back to its monoclinic form locally with an accompanying increase in volume.

- The local increase in volume introduces compressive stresses around the crack and slows its growth.

- This is also known as ‘tension expansion’ – a phenomenon otherwise known only in the case of steel. For this reason, zirconium oxide is also known as ‘ceramic steel’.

- The introduction of zirconia as a core material revolutionized dental ceramics.

- Its unique transformation toughening process made it possible to construct relatively long-span fixed partial dentures in both anterior and posterior locations.

Yttria stabilized zirconia

- The addition of minor components to the zirconia, such as yttrium, can produce a crystal that is both strong and resistant to crack generation because of the unique “transformation toughening” that occurs when zirconia goes from a tetragonal phase to a monolithic phase.

- It is this monolithic phase of zirconia that is resistant to breakage when used in full-coverage restorations.

Yttria stabilized zirconia Composition

Yttria-stabilized zirconia is Available as

- Blanks of different sizes and shapes.

- Both sintered and pre-sintered forms are available.

- Presintered form is a partially sintered form and is easier to mill.

- Following milling the dental laboratories complete the sintering to achieve full density.

- Blanks may be of a single color in which case manufacturers provide special coloring liquids for dipping or painting.

- Some manufacturers provide blanks in different shades (pre-shaded blanks).

Yttria stabilized zirconia Manufacture Ingredients that are in powder form are compacted (isostatic or axial) to form blanks of different sizes and shapes.

Properties of zirconia Dental zirconia is an extremely hard, dense, strong, and highly opaque material. Its properties are summarized in Table.

- Density – 9 g/cm3

- Melting point – 2715 °C

- Refractive index – 2.13

- Soluble in – Hydrofluoric acid and hot sulfuric acid.

- Flexure strength – 900 to1200 MPa

- MOE – 210 GPA

- CTE – 10.5 × 10-6/ °C

- Esthetics – Compared to PFM restorations zirconia-based restorations are more esthetic because of the elimination of metal display.

- However, when compared to other more translucent porcelains like lithium disilicate, zirconia appears less translucent and more opaque.

- Higher translucency will let more light into the restoration, and if used in conjunction with clear cement, a more life-like appearance can often be achieved.

- The lower translucency is because of its higher crystalline content.

- When of equal thicknesses, the most translucent zirconia is only 73% as translucent as conventional lithium disilicate.

Chipping of veneering ceramic

- Zirconia is a very strong material that can support an FDP.

- Nevertheless, chipping of the veneering ceramics has been reported, especially in the molar region.

- In several published studies, the veneer chipping rate was approximately 15% after 3 to 5 years.

- The chipping varied between different manufacturers of veneering ceramics.

- Laboratory studies have shown that low-fusing porcelains may be less resistant to cracking than high-fusing porcelains and the porcelain density is lower.

- Zirconia is a good thermal insulator that prevents heat transfer to the veneering porcelain, stopping it from becoming fully dense whether fast-find or fired at a low temperature.

- Also, fast cooling may create stress in the porcelain, which could lead to cracking.

- Any surface adjustment, such as grinding, sandblasting, and even polishing, can change the phase on the surface of the zirconia and may affect the stability and strength of the zirconia as well as the veneer porcelain.

Fracture of zirconia restorations

- Occasionally, total fractures of the zirconia core itself have been observed especially in the region of the second molars and over implants in the posterior region.

- Excessive or coarse grinding can cause cracks, which penetrate into the zirconia substructure, causing transformation that may initially hold these cracks closed.

- However, over time with exposure to the oral environment and reversal of the transformation stress, the cracks can begin to propagate.

- Furthermore, many of the “high-translucency zirconias” have low amounts of alumina, which is an important stabilizer.

- Lower amounts of alumina may cause excessive transformation, cracking, and tooth abrasion; however, clinical trials are expected to provide a more definitive answer.

Wear of opposing teeth

- Studies using natural teeth have shown that zirconia causes excessive wear of the natural tooth structure.

- Glazing alone is not sufficient as the glaze wears of exposing the rough surface underneath. Ongoing studies appear to show that polished zirconia is “wear-kind”.

- Therefore polishing, in addition to glazing is recommended currently to reduce the wear of natural teeth.

Ceria Stabilized Zirconia Alumina Ceramics

- Ceria-stabilized zirconia-alumina nanocomposite (ZrO2/Al 2O3) (Ce-TZP/A) have recently become available and is even claimed to be superior to Y-TZP in clinical use.

- Cerium oxide (CeO2), also known as ceric oxide, ceria, or cerium dioxide, is an oxide of the rare earth metal cerium. Its mode of action is similar to that of yttria.

Advantages And Disadvantages Of CAD/CAM Ceramic Restorations

CAD/CAM Ceramic Restorations Advantages

- Less waiting period. In some cases same-day restorations are possible.

- Stronger porcelain. Milled ceramic is stronger.

- In some systems, the scanning is done directly in the mouth so there is no need to make an impression.

- Reduced porosity, therefore greater strength.

- One visit (only in systems that mill full contour restorations with minimal subsequent processing.

- CAD/CAM restorations which employ core ceramics, and subsequent processing like sintering or glass infiltration, cramming, layering, etc., require more time).

- Lab equipment can be minimized as the equipment involved with metal casting and processing are not required.

- The ability to copy the original form of the tooth can produce restorations that are duplicates of the original tooth.

CAD/CAM Ceramic Restorations Disadvantages

- Costly equipment.

- Scanning the preparation is technique-sensitive.

- Still not as strong as PFM restorations.

- The problem of chipping of veneering ceramic in the case of zirconium core ceramics.

General Properties Of Fused Ceramics

The properties of porcelain vary widely depending on type and composition.

Strength

- The early porcelains were weak and brittle and tended to break easily (fracture or chipping).

- Current porcelain systems have considerably improved in strength and toughness.

- However, care still has to be taken during the manufacture and fabrication of these materials to ensure that flows that can lead to fracture are not incorporated.

- The strength of porcelain is usually measured in terms of flexure strength (or modulus of rupture).

Flexure strength

- It is a combination of compressive, tensile, as well as shear strength.

- The strengths of various types of porcelains are given in Table.

- The flexure strength of dental ceramic restorations varies from 70 MPa for feldspathic veneering porcelains to 1200 MPa for machined zirconia core restorations.

Tensile strength

- Porcelains are inherently brittle materials.

- Tensile strength is low because of unavoidable surface defects like porosities and microscopic cracks.

- When porcelain is placed under tension, stress concentrates around these imperfections and can result in brittle fractures.

Methods Of Strengthening

Porcelains are by nature brittle. Minute scratches, cracks, defects, porosity, etc., on the surface of the porcelain act as stress concentration points. When excessive tensile force or a sharp impact force is applied to the ceramic, the crack propagates through the crack tip until it penetrates through the entire thickness of the ceramic.

- This is the reason why surface glazing or polishing is important to eliminate as many of surface defects as possible.

- The methods to improve the fracture resistance of ceramic materials are described.

Residual Compressive Stresses through CTE Mismatch

- The method is to have layers of ceramic with slight differences in the coefficient of thermal expansion (CTE).

- The inner layer should have a slightly higher CTE than the outer layer.

- Thus on cooling to room temperature after firing the inner layer shrinks faster than the outer layer thereby pulling the outer layer inwards and creating compressive stresses within the outer layer.

- The principle is applied in both metal-ceramic restorations and all ceramic restorations where restorations are built up through layering.

- The inner metal coping usually has a higher CTE than the veneering ceramic.

- The innermost layers of ceramic like the opaquer will have a higher CTE than the enamel and dentin layers.

- Similarly in multilayered ceramic restorations the inner core will have a higher CTE than the outer veneering ceramic.

- (However, one must remember that CTE differences should be precisely calculated.

- Extreme differences in CTE can actually lead to the failure of the ceramic).

Residual Compressive Stresses through Thermal Tempering

- The method is used in the automobile industry to strengthen glass.

- Residual compressive stresses may be created by rapidly cooling the surface of the object while it is in a hot or molten state.

- The outer portion cools and forms a rigid skin while the inner portion is still hot.

- As the inner portion cools it shrinks and creates compressive stresses within the outer portion.

Residual Compressive Stresses through Ion Exchange

- The ion exchange process involves 2 ions with differences in size.

- When a ceramic object is placed in a bath of molten potassium salt, some of the sodium ions present in the surface glass is replaced by the potassium ions.

- The potassium ion is about 35% larger than the sodium ion.

- When the larger ion squeezes into the place formerly occupied by the smaller sodium ion large compressive stresses are created.

- The resulting compression leads to greater toughening of the glass than is possible by thermal strengthening.

- Glass thus treated is used in particular in the aircraft industry and other sectors where safety is all-important.

- The ion exchange process is also sometimes referred to as chemical tempering. One commercially available product GC Tuf-Coat (GC) is used for chemical toughening.

- This potassium-rich slurry is applied to the restoration and heated at 450 °C for 30 minutes in a furnace.

- However, the fracture resistance is confined to the surface of the glass to a thickness of just 100 µm.

Dispersion Strengthening

- Many modern glass-based ceramics use dispersion strengthening. The process involves the dispersion of a crystalline material within the ceramic which interrupts the formation of a crack.

- The crack cannot pass as easily through the crystal particle as easily as it does through the glass matrix.

- Dispersion strengthening is dependent on the type, size, CTE, and total content of the crystal within the ceramic.

- Examples of crystals used for dispersion strengthening are leucite, lithia disilicate, tetracyclic Formica, alumina, spinel, zirconia, etc.

Transformation Toughening

- The transformation toughening phenomenon is primarily associated with yttria-stabilized zirconia core ceramics.

- The process involves the stress-induced transformation of the material at the tip of the crack with accompanying volume expansion.

- This places the area at the tip of the crack under compression and thereby halts the progress of the crack.

- For further explanation see the section on yttria-stabilized zirconia.

Minimizing Stresses through Optimal Design

- Even the strongest ceramics can fail if the restoration is not designed properly.

- This includes sufficient thickness (at least 2 mm) for the ceramic, avoiding sharp internal line angles and point angles, avoiding marked changes in thickness, etc.

- Sharp angles or points on the internal surface of the restoration can act as stress raisers.

- The excessive thickness of porcelain in metal-ceramic restoration may lead to fracture because of insufficient support by the metal substructure.

- In the case of all ceramic FDPs, the connector should have sufficient height and width. It should be concave and should avoid sharp angles.

Strengthening by Bonding to a Stronger Substrate

- The strength of porcelain can be improved considerably when it is bonded to a stronger substructure.

- For example, in metal-ceramic restorations, the inner metal coping provides a stiff and stable support which reduces the tensile forces on the overlying ceramic.

- In all-ceramic restorations, the alloy frame is substituted by high-strength reinforced core ceramics like zirconia and alumina.

- The inner coping also acts as a skin, reducing the formation and propagation of internal cracks. This function is evident is ceramics bonded to platinum or gold foil.

- The foils obviously do not provide the same kind of high-strength support as seen in cast alloy copings but rather provide a protective inner skin that reduces internal defects.

Minimizing Fabrication Defects and Stresses

- The ceramic can be made stronger by proper manipulation and fabrication.

- Proper condensation and vacuum firing reduce porosity in the restoration.

- Proper cooling reduces the development of internal stresses and strains.

- Manufacturer’s instructions should be followed.

- Proper oxidation firing favors bond formation in metal ceramics.

Shear strength is low and is due to the lack of ductility caused by the complex structure of porcelain.

Factors affecting strength

- Composition

- Surface integrity Surface imperfections like micro-cracks and porosities reduce the strength. Thus grinding should be followed by glazing or polishing.

- Improper condensation Poor condensation introduces voids and reduces the density of the porcelain.

- Firing procedure Inadequate filing and overfishing weaken the structure.

Modulus Of Elasticity Porcelain has high stiffness. The stiffness values range from 69 to 210 GPa for the various ceramic systems ceramics.

Surface Hardness Porcelain is much harder (370 to 400 VHN) than natural teeth.

Abrasiveness Of Ceramics

- Wear of opposing teeth is a concern when using ceramic restoration.

- Unglazed or unpolished porcelain can cause severe wear of natural teeth especially if dentin is exposed.

- This can happen in cases of occlusal interferences or when excessive masticatory forces are involved as in bruxing.

- Thus, ceramic restorations are contraindicated in bruxers. Porcelain restorations must always be glazed or polished after grinding.

- Wear of enamel occurs by the gouging action caused by asperities (projecting crystals) on the ceramic surface.

- The abrasiveness of the ceramic depends on the type of asperities present. Alumina and zirconia are more abrasive than plain glass.

- Prolonged exposure to carbonated beverages increases the wear rate of enamel. Ultralow fusing ceramics are less abrasive to enamel than conventional ceramics.

- Ceramics having smaller crystal sizes or fiery particles show reduced enamel wear.

Thermal Properties Thermal conductivity Porcelain has low thermal conductivity which is important to prevent extreme cold or heat transmission to the sensitive dentin and pulpal tissues in cases of restorations in vital teeth.

Low Fusing And Ultralow Fusing Ceramics

Duceram LFC (Degussa) or Finesse (Dentsply)

- This relatively new porcelain is also referred to as a “hydrothermal low-fusing ceramic” (LFC).

- It is composed of an amorphous glass containing hydroxyl ions.

- It is claimed to have higher flexural strengths, greater fracture resistance, and lower hardness than feldspathic porcelain (hence less abrasion).

- The inner core for the crowns is made from Duceram Metal Ceramic porcelain which is leucite-containing porcelain placed on a refractory dye and baked at 930°C.

- The Duceram LFC on the surface is subsequently baked at 660 °C and can be surface characterized.

- There are no clinical studies substantiating these claims but in theory, the material sounds promising.

- It has been suggested that the material is “self-healing” as the potential cracks self-repair within the material.

- The wear rate is similar to that of the natural tooth.

- There are also some reports that the polishing of the surface with rubber wheels (for example Brassler polishing wheels) generates enough heat to “heal” the micro-cracks thus reducing the potential for crack propagation.

Finesse

- This is a low-fusing ceramic that can be used with many high-gold alloys as well.

- In addition to the standard shades, it is available in two new shades AO and BO to match bleached white teeth.

- LFCs do not etch very well and therefore cannot be used alone for bonded restorations.

- For this application, a thin coating of conventional porcelain must first be found.

- Coefficient of thermal expansion The CTE is an important property for dental ceramics especially for layered restorations.

- The CTE of the various layers should be closely matched. Extreme differences can induce a lot of stresses in the ceramic leading to immediate or subsequent failure.

- The CTE values range depending on the type of ceramic.

- Some of the veneering ceramics for metal-ceramic have values ranging from 6.4 to 7.8 × 10-6/°C.

- which is close to that of natural teeth. The CTE values for metal-ceramic alloys have to be lowered to improve their compatibility with ceramics.

Specific Gravity

- The true specific gravity of porcelain is 2.242.

- The specific gravity of fired porcelain is usually less (2.2 to 2.3), because of the presence of air voids.

Dimensional Stability Fired porcelain is dimensionally stable.

Chemical Stability

- It is insoluble and impermeable to oral fluids. Also, it is resistant to most solvents. However, hydrofluoric acid causes etching of the porcelain surface.

- A source of this is APF (acidulated phosphate fluoride) and stannous fluoride, which are used as topical fluorides.

- A 4-minute exposure of feldspathic porcelain to 1.23% APF or 8% stannous fluoride resulted in surface roughness which may lead to subsequent staining.

- The acid attacks the glassy phase rather than the crystalline phase.

- Hydrofluoric acid is used to etch the porcelain. Ceramic etchants are also used for intraoral repair of fractured ceramics.

Porcelain-metal and inter-ceramic bonds

- The interphase between the veneer porcelains and the supporting ceramic or metal core is an area of interest.

- The restoration can fail if the bond is weak. Many test methods have been used to determine bond strengths.

- One study (Petra et al, 2008) using a shear bond test has shown metal-ceramic systems to have a far higher bond strength than zirconia-based all-ceramic systems (12.5±3.2 for Vita In-Ceram YZ Cubes/Vita VM9, 11.5±3.4 for DC-Zirkon/ IPS e.max Ceram, and

- 9.4±3.2 for Cercon Base/Cercon Ceram S compared to 27.6±12.1, 26.4±13.4 MPa).

Esthetic properties Esthetics is a very complex subject and is an interplay of many factors. Esthetics is dependent on the ability of the material to mimic natural teeth in 5 important fields.

- Shape

- Texture

- Color

- Translucence

- Fluorescence

- In general, they have excellent esthetic properties, especially the all-ceramic restorations. The color stability is also excellent. It can retain its color and gloss for years.

- Different porcelains together with internal and external stains are available to mimic almost any effect seen in natural teeth.

- Some of the current ceramics are also able to match the fluorescence of natural teeth under certain artificial lighting, for example in discotheques.

Translucence

The esthetic qualities of porcelain vary according to the type of ceramic. Metal-ceramic restorations do not have the same level of translucence as some of the all-ceramic restorations.

These concerns include

- Darkening of the gums around the margins of the restoration

- The visibility of the margin is a dark line because of the display of metal.

- Certain esthetic concerns have been raised when the dense opaquer layer is visible through thin crowns (in metal-ceramic and In-Ceram crowns).

- However, this is more of an error in technique.

- The dentist must ensure an adequate depth of preparation (at least 1.2 to 1.4 mm) to ensure the sufficient thickness of dentin/enamel veneer to mask the opaque.

Not all metal-free ceramic crowns have the same degree of translucence. Some porcelains are highly translucent lithia disilicate crowns whereas others are highly opaque (zirconia).

Role of the underlying cement

- The underlying cement plays an important role in the case of translucent crowns.

- Resin cement of various shades and translucency are the cement of choice for bonding the more translucent ceramic restorations.

Biocompatibility

- Glazed porcelain is one of the most biocompatible materials in dentistry when placed in direct contact with tissues.

- However, ceramic dust which is produced when grinding or machining ceramics is harmful if inhaled.

- Proper evacuation of the dust and wearing of a mouth mask is mandatory.

Cementing Of Ceramic Restorations

The type of cement used depends on the type of restoration (metal ceramic or full ceramic) and its location (anterior or posterior).

- Both resin-based cement and glass ionomer-based cement have been used to bond ceramic restorations.

- Because of the translucency of some all-ceramic restorations example glass ceramic crowns), the underlying cement may influence the aesthetics (color) of the restoration.

- Therefore the shade of the cement used should be carefully selected.

Resin bonding agents

- Many clinicians advocate resin luting cements for ceramic restorations especially those with greater translucency for a number of reasons.

- Resin bonding generates the high bond strengths needed for such restorations to succeed.

- Esthetics at the margins is better with resin cement.

- Improved translucence.

- Improved fracture resistance and long-term survival.

- Reduces water access to the inner ceramic surface.

- Etching blunts the tips of microcracks within the ceramic thereby inhibiting crack propagation.

Bonding of the cement to the porcelain can be improved by

- Sandblasting

- Chemical etching

- Use of silane primers (for silica-based porcelains)

Sandblasting

- The inner surface of the ceramic restoration creates minute irregularities helping the cement to retain better.

- However, chemical etching appears to be superior.

- Following sandblasting clean in distilled water in an ultrasonic bath for 10 minutes.

Etching of porcelain

- Ceramic restorations which are bonded using resin cement (usually veneers and inlays) have to be etched.

- Etching improves the bond of the resin to the ceramic.

- Etching is commonly done with hydrofluoric acid or ammonium fluoride (NH4HF2).

- The acid attacks and selectively dissolves the inner surface of the ceramic.

- The acid is available in two concentrations 5% and 9.5%. An etching time of 2 minutes is usually sufficient.

- Overetching can result in the formation of a white residue on the surface of the porcelain.

- This is believed to be a mix of acid-reaction salts and crystal fragments.

- Following etching the restoration is cleaned by placing in ethanol followed by a 5-minute immersion in an ultrasonic bath.

- The tooth surface is also etched using phosphoric acid. Before placing the cement, a bond agent is applied to both surfaces (tooth and porcelain).

Precautions

- HF has the ability to readily penetrate skin tissues (often without causing an external burn), and

- It causes extensive internal tissue damage, as well as alters blood calcium levels (due to the formation of CaF2), which can lead to dangerous heart arrhythmia.

- Suitable precautions should be taken while handling concentrated HF.

Bonding of alumina and zirconia-based restorations

Zirconia and alumina restorations can be cemented traditionally with a range of conventional cement for a number of reasons.

- Alumina and zirconia-based ceramics cannot be etched or silanated that easily when compared to are silica-based ceramics.

- They are more opaque and so the cement does not significantly affect esthetics.

- Zirconia/alumina restorations with good retention may be cemented with glass ionomer, resin-modified glass ionomer, and carboxylate cement, or with self-adhesive resin cement.

- However, restorations with less than ideal retention should be bonded with adhesive resin cement, an enamel/dentin bonding agent, and a special zirconia primer.

Silane treatment

- Silanes are a class of organic molecules that contain one or more silicon atoms.

- The specific silane typically used in dentistry for both intraoral repair and treatment of ceramic restorations is 3-metha aryloxy propyl trimetoxy silane.

- This silane is a difunctional molecule. One side of this molecule is nothing more than a methacrylate group capable of copolymerization with methacrylate-based adhesives and resins routinely used for dental procedures.

- The other side, after hydrolysis, has the potential to form chemical bonds to the porcelain surface.

- To be able to function as a coupling agent and interact chemically with porcelain surfaces, silane must first be hydrolyzed or activated with acetic acid. This is done with acetic acid.

The silane comes in 2 forms

- Single bottle (active or hydrolyzed form)

- Two-bottle (nonhydrolyzed form) Two-bottle silane systems typically consist of a nonhydrolyzed silane/ ethanol solution in one container and an acetic acid/water solution in the other.