Waxes In Dentistry

“What are waxes in dentistry? A detailed question and answers guide”

During construction of a denture and many other appliances, wax is used as a modeling material. Different types of waxes are used to prepare patterns for alloy castings.

There are many varieties of waxes used, both in the clinic and laboratory. Each has particular properties depending on what it is used for. Their basic constituents are essentially similar, their exact proportion is different.

Components Of Dental Waxes

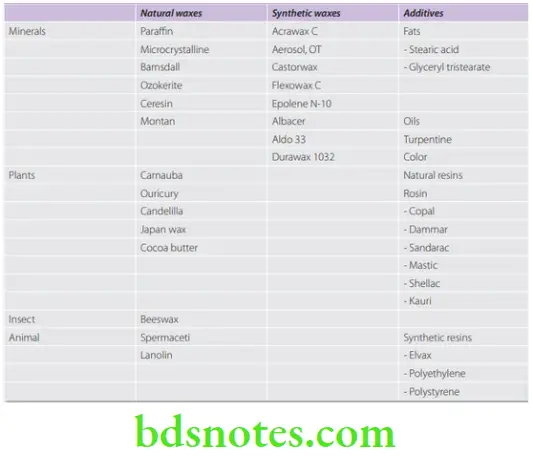

Dental waxes contain natural waxes, synthetic waxes and additives

Read And Learn More: Basic Dental Materials Notes

Chemical Nature Of Waxes

Natural waxes are long chain, complex combinations of organic compounds of reasonably high molecular weight. The two principal groups of organic compounds contained in waxes are—

- Hydrocarbons, e.g. saturated alkanes, and

- Esters, e.g. myricyl palmitate (bees wax).

Some waxes, in addition, contain free alcohol and acids.

Ester—formed from union of higher fatty acids (e.g. carboxylic acid) with higher aliphatic alcohol with elimination of water.

Alcohol + Fatty acid Ester + Water

“Understanding waxes in dentistry through FAQs: Types, composition, and uses explained”

“Importance of studying waxes for dental professionals: Questions explained”

Mineral Waxes

- Paraffin and microcrystalline waxes These are distillation products of petroleum. They are both hydrocarbons. Paraffin (melts 40–70 °C) tends to be brittle. Microcrystalline (60–90 °C) is more flexible and tougher.

Plant Waxes

- Carnauba Carnauba, also called Brazil wax and palm wax, is a wax of the leaves of the palm Copernicia prunifera, a plant native to and grown only in the northeastern Brazil. In its pure state it usually comes in the form of hard yellow-brown flakes. Melting range is 84–91 °C.

- Ouricury Ouricury wax is a brown-colored wax obtained from the leaves of a Brazilian Feather Palm Syagrus coronata or Cocos coronata by scraping the leaf surface. It melts between 79–84 °C.

- Both Carnauba and Ouricury raise melting range and hardness of paraffin.

- Candelilla It is a wax derived from the leaves of the small Candelilla shrub native to northern Mexico and the southwestern United States, Euphorbia cerifera and Euphorbia antisyphilitica. It is yellowish-brown, hard, brittle, aromatic, and opaque to translucent. Melting range is 68 to 75 °C. Mainly hardens paraffin wax.

- Japan wax and cocoa butter These are not true waxes but are chiefly fats. Japan wax is also known as sumac wax, China green tallow, Japan tallow, etc. It is obtained from the lacquer tree and the Japanese wax tree which are native to Japan and China. It is pale yellow, sticky, tough, malleable, has a gummy feel and melts at 51 °C. Cocoa butter is brittle. Japan wax improves tackiness and emulsifying ability of paraffin.

“Common challenges in mastering wax knowledge effectively: FAQs provided”

Insect Wax

- Beeswax (63–73 °C) Brittle at room temperature, plastic at body temperature. Its addition reduces brittleness.

- Shellac wax From the lac insect Kerria lacca.

Animal Wax

- Spermaceti is found in the spermaceti organ inside the sperm whale’s head. It is not widely used. Mainly used as a coating for dental floss.

- Lanolin is a wax obtained from wool, consisting of esters of sterols.

Synthetic Waxes

- The natural waxes are not consistent in their composition, and thus their properties. To overcome this, synthetic waxes are used. These are carefully prepared under controlled conditions to give standardized reliable results. They are highly refined unlike natural waxes which are frequently contaminated. Their use is still limited.

- Ozokerite It is an earth wax found in western US and central Europe. It improves the physical of paraffin.

- Montan Montan wax is a fossilized wax extracted from coal and lignite. It is very hard, reflecting the high concentration of saturated fatty acids and alcohols. It is hard, brittle and lustrous. Although dark brown and smelly, they can be purified and bleached. It can be substituted for plant waxes.

- Ceresin It is obtained from petroleum and lignite refining. They are harder and are used to raise melting range of paraffin.

- Barnsdall It raises melting range and hardness, reduces flow of paraffin.

Wax Additives

- Gums They are viscous, amorphous exudates from plants that harden when exposed to air. They are complex substances mainly made of carbohydrates. They either dissolve in water or form sticky, viscous liquids, e.g. gum Arabic and tragacanth.

- Fats They are tasteless, odorless and colorless substances. They are similar to wax but have lower melting temperatures and are softer. Chemically they are composed of glycerides, e.g. beef tallow and butter. They can be used to increase melting range and hardness of waxes.

- Oils They lower the melting point of paraffin. Hydrocarbon oils soften waxes. Silicone oils improve ease of polishing of waxes.

- Resins are exudates of certain trees and plants (except shellac which is from insects). They are complex, amorphous mixtures of organic substances. They are insoluble in water. They improve toughness. They are also used to make varnishes (by dissolving in an organic solvent).

- Synthetic resins They are also used.

“Factors influencing success with wax selection: Q&A”

Classification Of Dental Waxes

According to Origin (Described Earlier)

- Mineral

- Plant

- Insect

- Animal

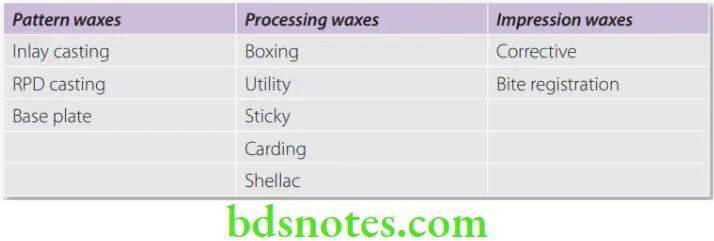

According to Use

“Steps to explain types of waxes in dentistry: Pattern wax vs boxing wax vs utility wax: Q&A guide”

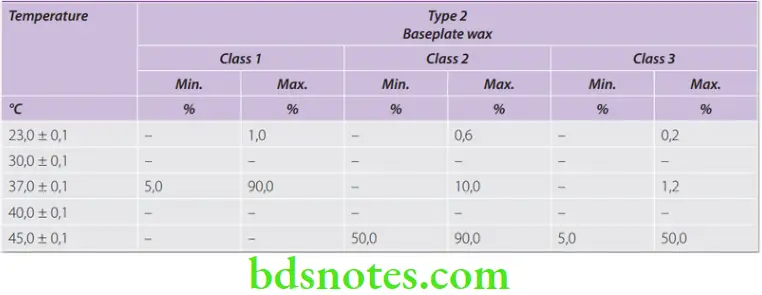

ISO classification (ISO 15854: 2005) for casting inlay and baseplate wax

The ISO recognizes 2 types of waxes which are further sub-classified according to their flow characteristics that represent their hardness.

Type 1 (Casting wax) – for cast metal restorations

- Class 1 – Soft

- Class 2 – Hard

Type 2 (Baseplate wax) – for denture bases and occlusion rims

- Class 1 – Soft

- Class 2 – Hard

- Class 3 – Extra hard

General Properties

Waxes have a number of important properties in relation to their dental use. Different uses require different properties. Waxes for patterns probably require most careful balance. Some of the important properties are

- Melting range

- Thermal expansion

- Mechanical properties

- Flow

- Residual stresses

- Ductility

Melting Range

- Waxes have melting ranges rather than melting points. Mixing of waxes may change their melting range. Melting range varies depending on its use.

Thermal Expansion

- Waxes expand when subjected to a rise in temperature and contract as the temperature is decreased.

- Coefficient of thermal expansion and its importance Dental waxes and their components have the largest CTE among the materials used in restorative dentistry. Temperature changes in wax patterns after removal from the mouth can produce inaccuracies in the finished restoration.

“Role of pattern wax in creating precise dental castings: Questions answered”

Mechanical Properties

- The elastic modulus, proportional limit and compressive strength of waxes are low compared to other dental materials. These properties are strongly dependent on the temperature. As temperature decreases, the properties improve.

Flow

Flow is an important property, especially in inlay waxes. When melted, the wax should flow readily into all the parts of the die. Flow is dependent on

- Temperature of the wax

- Force applied

- The length of time the force is applied.

Flow increases as the melting point of the wax is approached.

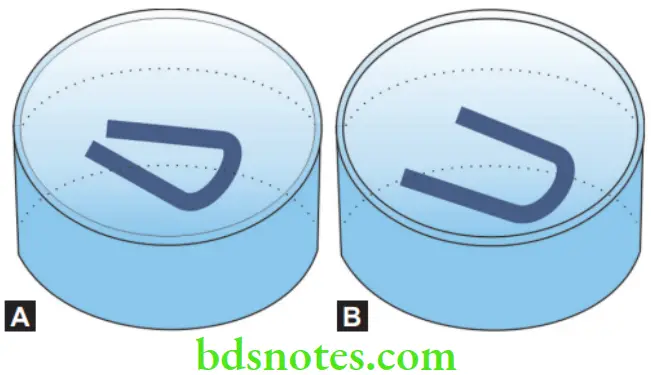

Residual Stress

- Regardless of the method used to make a wax pattern, residual stresses will exist in the completed pattern. The stress may be compressive or tensile in nature.

- Example A When a specimen is held under compression during cooling, the atoms and molecules are forced closer together. After the specimen is cooled to room temperature and the load is removed, the motion of the molecules is restricted. This restriction results in residual stress (hidden stresses) in the specimen. When the specimen is heated, release of the residual stress is added to the normal thermal expansion, and the total expansion is greater than normal.

- Example B When a specimen is cooled while under tension, the release of the residual tensile stress results in a dimensional change that is opposite to thermal expansion, i.e., it can result in overall contraction of the specimen.

Ductility

- Like flow, the ductility increases as the temperature of the wax is increased. In general, waxes with low melting points have greater ductility than those with high melting points.

Pattern Waxes

Many dental restorations or prostheses are first made with pattern waxes. The wax is later replaced with the permanent material, e.g. cast gold alloys, cobalt-chromium-nickel alloys, or polymethyl methacrylate resin.

All pattern waxes have two major qualities which cause serious problems in their use—thermal change in dimension and tendency to warp or distort on standing, e.g. inlay casting wax, RPD casting wax and baseplate wax.

“How does boxing wax improve impression techniques? FAQ explained”

Pattern Waxes Types

- Casting waxes

- Inlay

- Removable partial denture (the metal frame)

- Milling wax

- Baseplate wax (used in the construction of complete and partial denture).

Inlay Casting Wax

The inlay casting wax is among the oldest waxes in dentistry.

Pattern Waxes Uses

- The pattern for inlays, crowns and FPDs is first made in wax, and then replaced by metal during casting.

- Direct and indirect techniques If the pattern is made directly in the tooth (in the mouth), it is said to be prepared by direct technique (Class 2 wax). If it is prepared on a replica of the tooth (die), it is called indirect technique (Class 1 wax).

Ideal Requirements of Inlay Casting Waxes

- When softened, the wax should be uniform, there should be no graininess or hard spots in the plastic material.

- The color should contrast with the die. A definite color contrast helps in identifying and finishing of margins.

- The wax should not flake or crumble when the wax is softened.

- The wax should not chip, flake or tear during carving.

- During burnout (500 °C), it should vaporize completely without residue.

“Early warning signs of gaps in understanding wax types: Common questions”

- The wax pattern should be completely rigid and dimensionally stable at all times until it is eliminated.

- It should be sufficiently plastic slightly above mouth temperature and become rigid when cooled to mouth temperature (for class I waxes).

- The wax should have good flow when heated and set rigidly when cooled (at the recommended temperature.

Classification

According to ISO 15854:2005, inlay casting waxes are classified as

- Class 1 Soft—Extraoral or laboratory use

- Class 2 Hard—Intraoral use

Supplied As

- Blue, green or purple sticks or cakes. Also available as small pellets and cones. The waxes are also available in preformed shapes.

- Commercial Names Harvard, Kerr, etc.

Composition

- Paraffin wax, gum damar, carnauba or candelilla and coloring agents.

- Paraffin wax (40–60%) This is the main ingredient. It is used to establish the melting point. Different varieties, with different melting points can be produced. Paraffin wax flakes trimmed do not give a smooth surface, so other waxes are added to modify.

- Ceresin (10%) Partially replaces paraffin. Increases toughness. Easy to carve.

- Gum damar (1%) Damar resin (a natural derivative from pine tree) improves the smoothness during molding and makes it more resistant to cracking and flaking. It also increases toughness of the wax and enhances the luster of the surface.

- Carnauba wax (25%) This wax is quite hard and has a high melting point. It is combined with paraffin to decrease the flow at mouth temperature. It has an agreeable odor and gives glossiness to the wax surface.

- Candelilla wax This wax can be added to replace carnauba wax. It contributes the same qualities as carnauba wax, but its melting point is lower and is not as hard as carnauba wax.

- Synthetic waxes In modern inlay waxes, carnauba wax is often replaced partly by certain synthetic waxes (Montan). Because of their high melting point, more paraffin can be incorporated and the general working qualities are improved.

“Asymptomatic vs symptomatic effects of ignoring wax type principles: Q&A”

Properties of Inlay Wax

Class 1 inlay wax is meant for use in the laboratory whereas, Class 2 wax is used in the mouth (indirect technique). Obviously, both would have slightly different properties.

Flow

Requirements according to ISO 15854:2005

- At 45 °C – Both Class 1 and Class 2 should have a flow between 70 to 90%.

- At 37 °C – Class 2 should not flow more than 1%.

- At 30 °C – Class 1 should not flow more than 1%.

It is clear that

Class 1 inlay wax This type melts and flows, when heated to around 45 °C. This temperature is tolerated by the patient. Good flow at this temperature ensures good reproduction of the inlay cavity. The wax cools down and hardens at 37 °C (mouth temperature), allowing the operator to carve and shape it in the mouth.

Class 2 inlay wax This type on the other hand hardens at 30 °C (room temperature). This wax is more suitable for the laboratory. The flow characteristics are not suitable for use in the mouth.

Thermal properties

- Thermal conductivity The thermal conductivity of these waxes is low. It takes time to heat the wax uniformly and to cool it to body or room temperature.

- Coefficient of thermal expansion Inlay wax has a high CTE. It has a linear expansion of 0.7% with increase in temperature of 20 °C. Its thermal changes are higher than any other dental material.

- Importance This property is more significant in direct technique because contraction of the pattern can occur when it is taken from mouth to room temperature (especially in air conditioned rooms or in cold climates).

- Factors affecting If the wax is allowed to cool under pressure, its thermal properties are changed. When reheated, the linear CTE is increased. The temperature of the die and the method used to apply pressure on the wax as it solidifies also influences the CTE.

Wax distortion

Wax distortion is the most serious problem in inlay wax. It is due to release of stresses in the pattern caused due to

- Contraction on cooling

- Occluded gas bubbles

- Change of shape of the wax during molding

- From manipulation—carving, pooling, removal, etc.

Thus the amount of residual stress is dependent on

- The method of forming the pattern

- Its handling, and

- Length of time and temperature of storage of the wax pattern

Causes of distortion Distortion is due to any method of manipulation that creates inhomogeneity of wax involving the intermolecular distance.

“Can targeted interventions reduce risks of wax-related complications? FAQs provided”

Factors causing distortion under control of the operator cannot be totally eliminated. Distortion of the wax can occur

- If wax is not at uniform temperature when inserted in the cavity, some parts of the wax pattern may thermally contract more than others when stresses are introduced.

- If wax is not held under uniform pressure during cooling.

- If fresh wax is melted and added in an area of deficiency, the added wax will introduce stresses during cooling.

- During carving, some molecules of wax will be disturbed and stresses will result.

To avoid

- Minimal carving and change in temperature.

- Minimal storage of pattern. Invest immediately.

- Store it in a refrigerator if necessary.

Some relaxation and distortion of pattern occurs regardless of the method used. It cannot be totally eliminated. It can only be reduced to a point which is not of clinical importance.

Residue on ignition

- Waxes vaporize during burnout. ISO 15854:2005 limits the nonvaporizable residue to a maximum of 0.1%. Excess residue can result in an incomplete casting.

Manipulation of Inlay Wax

Direct technique

- Hold the stick of wax over the visible flame and rotate it rapidly until it becomes plastic taking care not to volatilize the wax. The softened wax is shaped approximately to the form of the prepared cavity.

- After the wax is inserted into the cavity, it is held under finger pressure while it solidifies. The wax should be allowed to cool gradually to mouth temperature. Cooling rapidly by application of cold water results in differential contraction and development of internal stresses.

- Localized reheating of wax with warm carving instruments has a similar effect and more distortion may occur. A cold carving instrument should be used for direct wax pattern. Withdraw the wax pattern carefully in the long axis of the preparation. The pattern should be touched as little as possible with the hands to avoid temperature changes.

Indirect technique

Inlay pattern is prepared over a lubricated die. If molten wax is used, very little residual stresses occur.

- Dipping method In case of full crowns, the die can be dipped repeatedly, into hot liquid wax. The wax is allowed to cool, carved, and removed from the die.

- Softening in warm water This technique is not recommended because

- Soluble constituents may leach out and the properties of wax will change

- Water gets into the wax causing splattering on the flame, interference with the softening of the wax surface and distortion of the pattern on thermal changes.

- Addition The wax is melted and added in layers using a spatula or a brush.

“Differential applications of anterior vs posterior procedures: Questions answered”

Polishing

Polishing is done by rubbing with a silk cloth.

Note

- Invest all wax patterns as soon as possible to avoid distortion.

- Waxes oxidize on heating. Prolonged heating causes it to evaporate. There will also be darkening and precipitation of gummy deposits. To avoid this, use the lowest temperature needed for melting.

RPD Casting Wax

The partial denture casting waxes are quite unlike the inlay casting waxes in appearance and handling properties. Currently, no ADA or ISO specification have been formulated for these waxes. However, a US federal specification (U-W-140) has been formulated to cover these waxes. These specifications are different from those of inlay waxes.

Uses

- To make patterns of the metallic framework and sprues of removable partial dentures.

Supplied As

It is available in different forms.

- Sheets 0.40 and 0.32 mm thickness

- Preformed shapes

- Round (10 cm), half round and half pear-shaped rods

- Reticular, grid or mesh form

- Clasp shapes

- Other forms

- Bulk wax as blocks or in containers

- Rolls or coils of various diameters ranging for 2 to 5 mm for forming sprues.

“Steps to explain composition of waxes in dentistry: Natural waxes vs synthetic waxes vs additives: Q&A guide”

Properties

These waxes are tacky and highly ductile as they must adapt easily and stick onto the refractory cast. They should copy accurately the surface against which they are pressed.

The pattern for the RPD frame is made on a special cast known as the refractory cast. Since the wax comes in preformed shapes, it is quite easy to assemble.

The wax forms are sticky and pliable and can be adapted easily onto the cast. After the pattern is completed, it is invested and ignited. Like inlay wax, they too must vaporize with little residue during burnout.

“Role of natural waxes in ensuring biocompatibility: Questions answered”

Milling Wax

Synonyms Machinable wax

Milling or machinable wax is wax that can be shaped by milling or machining using CAD/CAM or dental drills. Machinable wax is an extremely hard wax with high melting temperature that is formulated to deliver machining properties including high resolution detail. The wax pattern formed after machining is invested and cast like regular casting waxes.

Available as

Machinable wax is available as

- Blocks

- Cylinders

- Discs

- Cakes in containers

Properties

It is harder and has a higher melting temperature than most other waxes. It powders or flakes on milling.

Hardness : 53 (Shore “D” Scale)

Specific Gravity : 0.92

Melting Point : 115 ºC

Burnout Residue : 0.0066%

Flexural Modulus : 45,250 PSI

Coefficient of Thermal Expansion: 7.5 x 10–5 (cm/cm/ºC)

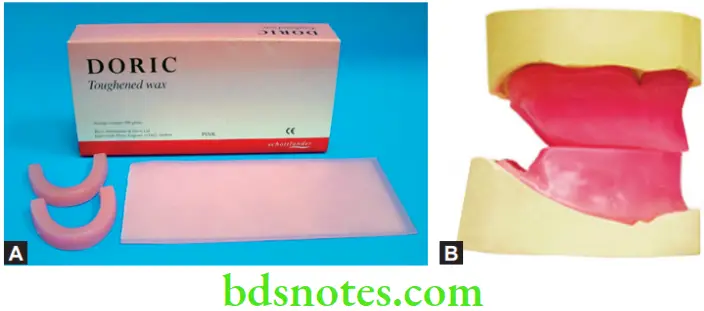

Baseplate Wax

Most students would be familiar with this wax. It is sometimes referred to as modeling or Type 2 (ISO 15854) wax. They are classified under pattern waxes because they are used to create the form of dentures and appliances made of acrylic and like materials. Ideally, these waxes should be easy to carve, should not chip and break at try-in and should boil out without leaving any oily residue.

“How do synthetic waxes improve material properties? FAQ explained”

Baseplate Wax Uses

These waxes are used for the following

- To make occlusion rims.

- To form the contour of the denture after teeth are set.

- To make patterns for orthodontic appliances and other prostheses which are to be constructed of plastics.

Baseplate Wax Classification

- Type 1 Soft — for building veneers

- Type 2 Hard — to use in mouths in normal climates

- Type 3 Extra-hard — for use in tropical climates

Baseplate Wax Supplied As

- Sheets of pink or red color.

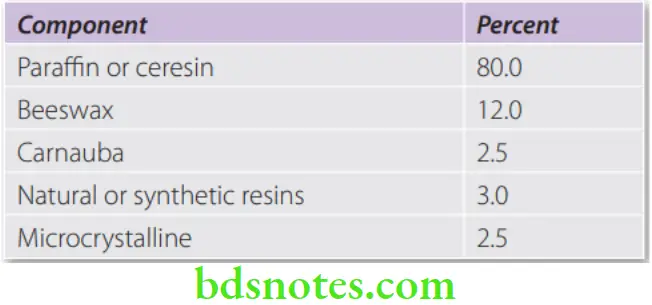

Baseplate Wax Composition

“Early warning signs of untreated composition concerns: Common questions”

Processing Waxes

These are those waxes used mainly as accessory aids in the construction of a variety of restorations and appliances, either clinically or in the laboratory, e.g. boxing wax, beading wax, utility wax, blockout wax, carding wax and sticky wax.

Boxing Wax And Beading Wax

Uses

- Used to build up vertical walls around the impression, in order to pour the stone and make a cast. The procedure is known as boxing.

Supplied As

- Boxing wax as sheets, beading wax as strips.

Advantages of Beading and Boxing

- Preserves the extensions and landmarks.

- Controls the thickness of the borders.

- Controls the form and thickness of the base of the cast.

- Conserves the artificial stone.

Properties

- They are pliable and can be adapted easily. A slight tackiness allows it to stick to the impression.

- Note The terms carding wax and boxing wax have been used interchangeably. Carding wax was the original material on which porcelain teeth were fixed when received from the manufacturer. Boxing wax is a more acceptable term.

“Asymptomatic vs symptomatic effects of delayed maintenance: Answered”

Technique

- Beading wax is adapted around the periphery. This wax should be approximately 4 mm wide and 3–4 mm below the borders of the impression. The height is adjusted until a boxing wax strip extends approximately 13 mm above the highest point on the impression. Stone is vibrated into the boxed impression.

Utility Wax

Composition

- Consists mainly of beeswax, petrolatum, and other soft waxes in varying proportions.

Supplied As

- It is available in the form of sticks and sheets.

Uses

- It is used to adjust contour of perforated tray for use with hydrocolloids (e.g. to raise flange height, to extend the tray posteriorly, to raise palatal portion of the tray in cases of deep palate, etc.). It is pliable and can be easily molded. It is adhesive and can stick to the tray.

Sticky Wax

Composition

- It consists mainly of yellow beeswax, rosin, and natural resins such as gum dammar.

Properties

- It is sticky when melted and adheres closely to the surfaces to which it is applied. At room temperature, it is firm, free from tackiness, and brittle.

Uses

- Used for joining (assembling) metal parts before soldering and for joining fragments of broken dentures before repair procedure. A variety of other uses, mainly joining, are possible with this wax.

Carding Wax

- Carding wax is used by manufacturers for the packaging of acrylic or porcelain teeth. They are soft, tacky and pliable at room temperatures. The are available as sheets or strips.

“Can lifestyle changes support post-wax procedure care? FAQs provided”

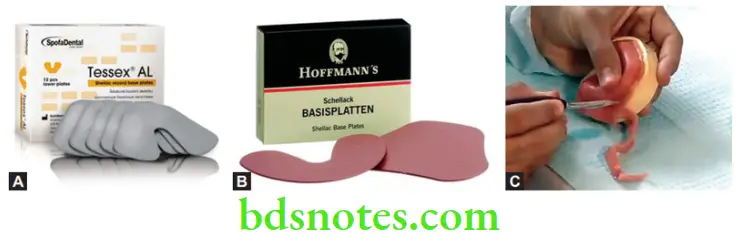

Shellac

Shellac was once extensively used in dentistry to fabricate temporary denture bases and custom trays. It is also used for bite registration.

Composition

- It contains shellac wax which is a wax from the lac insect Kerria lacca, plasticizers like stearin and stearic acid and fillers like mica (strength), talc. Some contain aluminum which is also used as a filler to adjust viscosity. It may be white (bleached), brown (natural color) and pink or bronze (dye).

- Heating of the shellac in water above 70 °C causes leaching of the plasticizers. Heating over flame above 100 °C results in polymerization with release of water (characterized by bubbling). This results in a marked increase in its viscosity (becomes stiffer).

Manipulation

- Being a thermoplastic material, it is manipulated by softening with heat to adapt, cut and shape it.

Drawbacks

- Again being a thermoplastic material, it is affected by heat and is, therefore, potentially unstable and subject to distortion. It is now largely replaced by resins which are more stable.

“Differential applications of functional vs aesthetic considerations: Questions answered”

Impression Waxes

These are used to record non-undercut edentulous portions of the mouth, and are generally used in combination with other impression materials such as polysulfide rubber, ZOE, or dental impression compound, e.g. corrective impression wax, bite registration wax.

Corrective Impression Wax

Waxes were used widely in the past for making dental impressions. Waxes are highly unstable and susceptible to distortion and are, therefore, not particularly suited for conventional impressions. However, they may be used in certain situations.

Types

- Aluwax

- Korecta wax (No. 4) (extra soft – orange)

- Iowa wax—Available as 6 inch sticks or in a small container

- H-L physiologic paste (yellow-white)

- Adaptol (green)

Uses

It is used as a wax veneer over an original impression to contact and register the details of the soft tissues.

- To make functional impression of free end saddles (Class I and II removable partial dentures).

- To record the posterior palatal seal in dentures.

- Functional impression for obturators.

Composition and Properties

They consist of paraffin, ceresin and beeswax. It may also contain metal particles like copper or aluminium. One product uses aluminum particles. The flow at 37 °C is 100%. These waxes are subject to distortion during removal from the mouth. They should be poured immediately.

Each grade is designed for a specific purpose.

“Steps to explain disadvantages of waxes in dentistry: Brittleness vs thermal sensitivity vs handling complexity: Q&A guide”

Bite Registration Wax

Uses

- It is used to record the relationship between the upper and lower teeth. This is necessary in order to mount the casts correctly in the articulator.

Supplied As

- U-shaped rods or wafers. A thin metallic foil may be present on the undersurface or between the wax layers.

Composition

- Beeswax or paraffin or ceresin. Some contain aluminum or copper particles.

Procedure

- The wax is softened in warm water. The soft wax is then placed between the teeth and the patient is asked to bite. After the wax hardens, it is then taken out and placed in chilled water.

“Early warning signs of undiagnosed wax disadvantages: Common questions”

“Role of brittleness in limiting wax longevity: Questions answered”

It is replaced back in the mouth and the patient asked to occlude for a final check. The casts of the patient is placed in the indentations formed by the teeth in the wax. It is then mounted with plaster on the articulator. Mounting should not be delayed as wax distortion can lead to inaccurate results. Bite registration can be done with other materials like zinc oxide, eugenol and silicones.

Leave a Reply